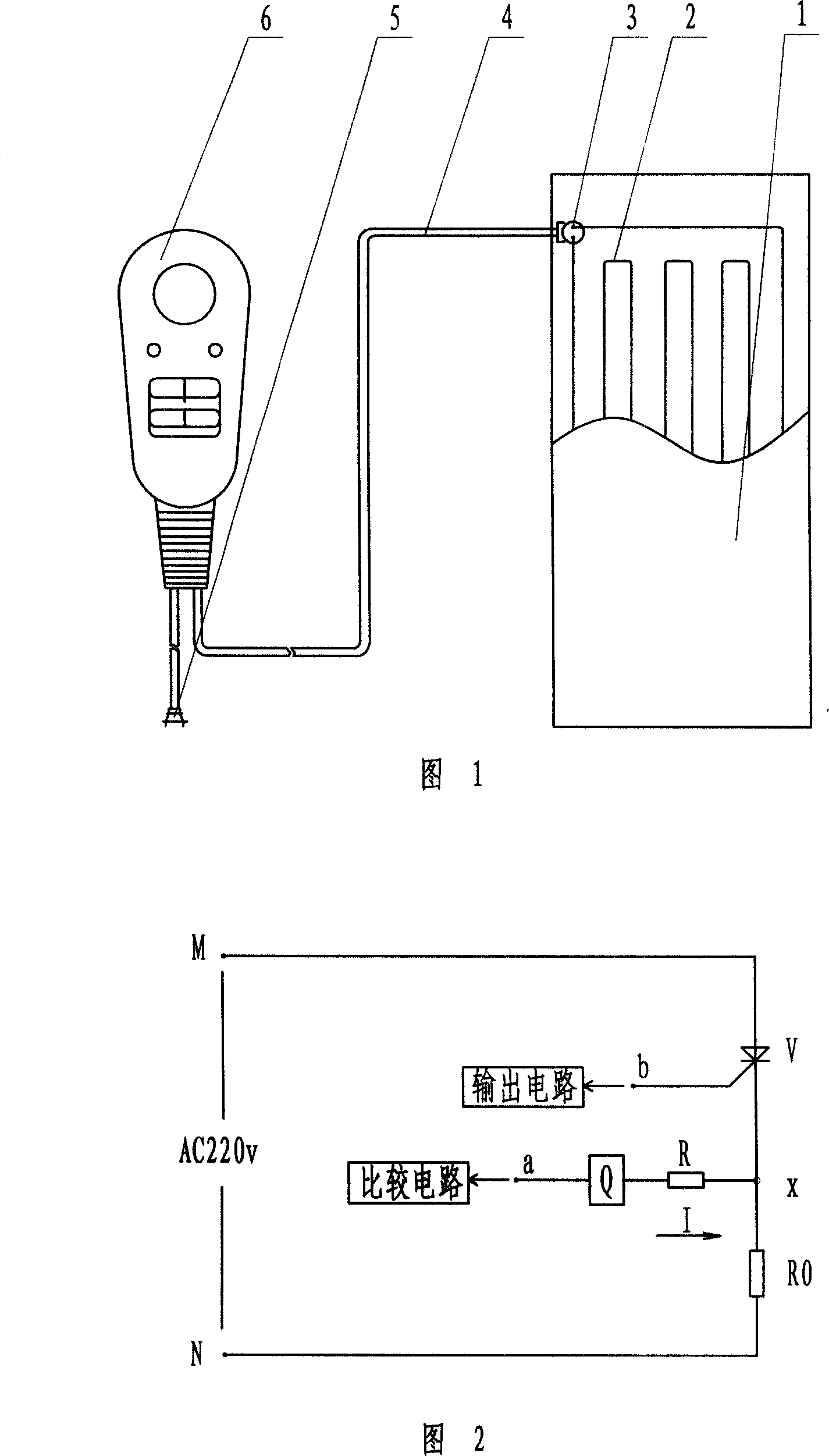

Whole circuit temperature-controlling electric heating device

A circuit and electric heating technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of harmonic interference of phase-shift temperature control appliances, high failure rate of appliances, and difficulty in temperature control, so as to achieve no harmonic interference. , high safety, no effect of electromagnetic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

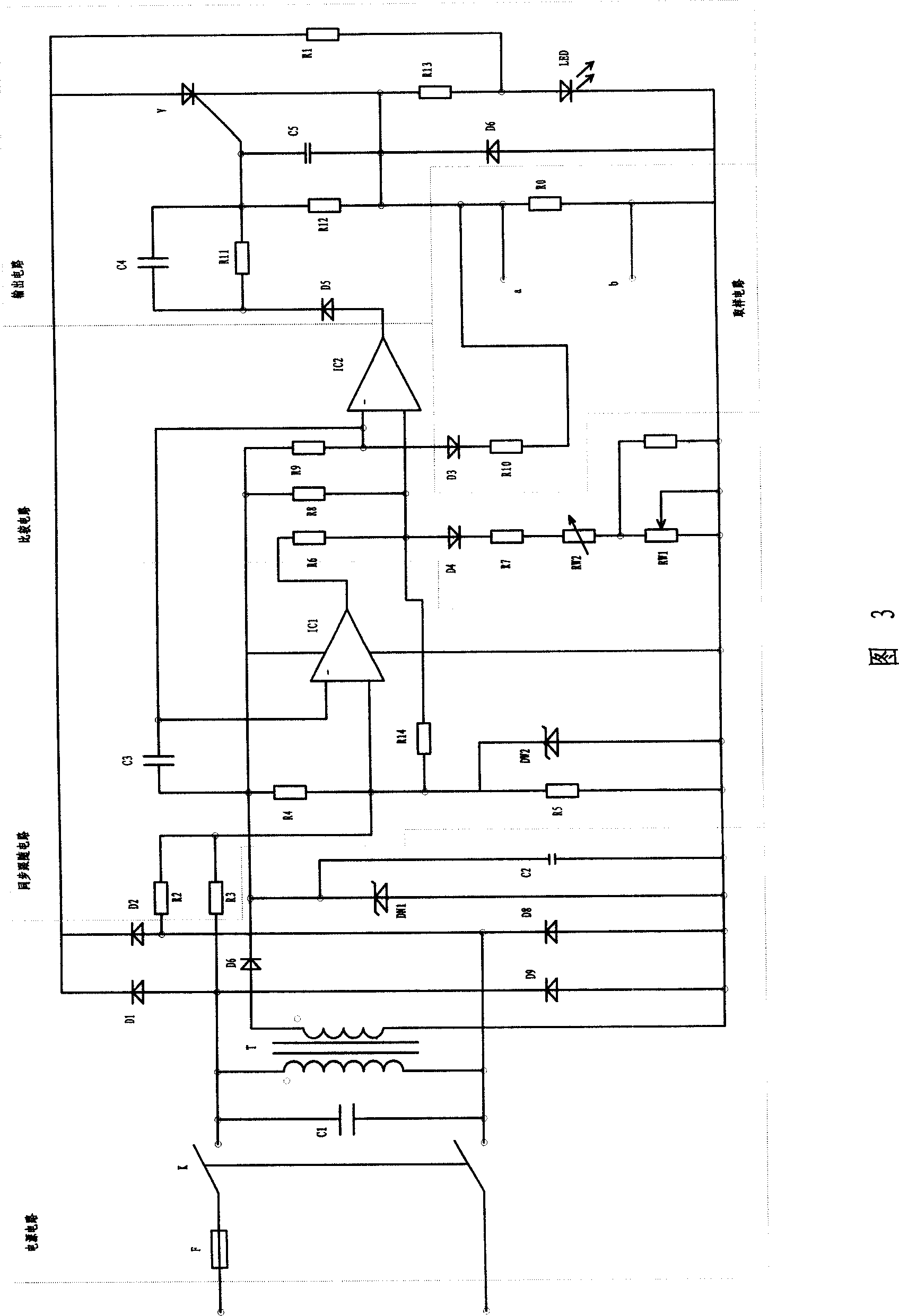

[0029] Embodiment 1, the electrical schematic diagram of the full-wave working power supply, such as image 3 As shown, the power supply circuit is divided into two circuits, one is composed of fuse F, transformer T, diode D6, voltage regulator DW1, and filter capacitor C2, which provides the control circuit with a regulated power supply; the other is composed of diode D1 1 , D2, D8, and D9 are composed of the executive element thyristor V, which is controlled by the control circuit to apply voltage to the heating element RO.

[0030] The synchronous follower circuit is composed of resistors R2, R3, R4, R5, operational amplifier IC1, capacitor C3, and limit regulator DW2. The potential of the negative input terminal of the operational amplifier IC1 is taken from the negative input terminal of the comparison circuit of IC2. R4 and R5 are bias resistors, and R2 and R3 follow the resistors synchronously to provide the input voltage of the positive terminal of IC1, so that the ou...

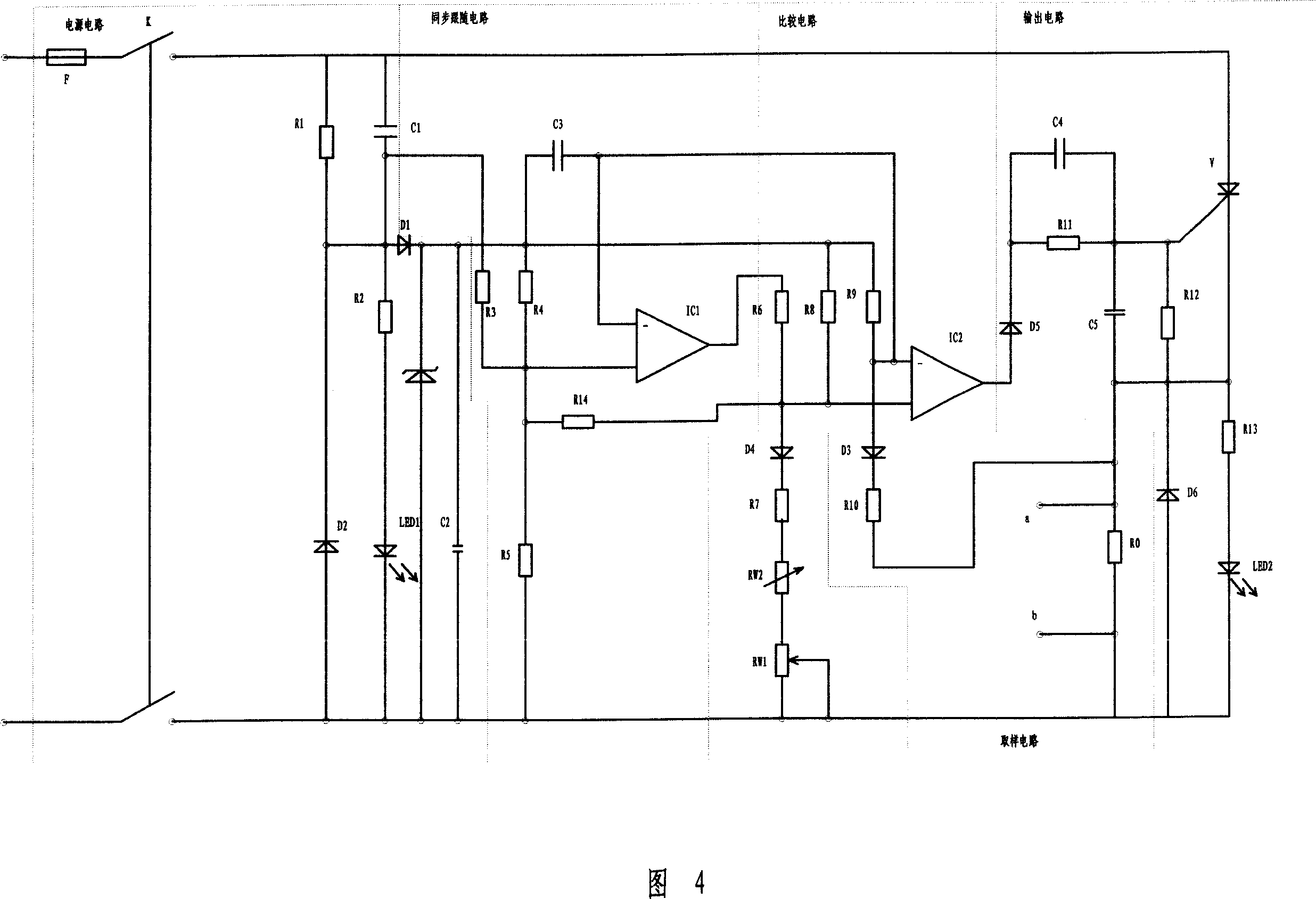

Embodiment 2

[0033] Embodiment 2, as shown in the figure, is a schematic diagram of the half-wave control circuit. Its principle is the same as that of the full-wave control, except that the control circuit is in the half-wave control state, and the heating element RO is controlled to work when the grid voltage is half-wave. The wave control circuit outputs a low level, the thyristor V is turned off, and the heating element RO does not work all the time.

[0034] In order to prevent the output circuit and output signal of the control circuit from interfering with the sampling circuit and causing the control circuit to get out of control, two methods are adopted. The first is that the output circuit adopts transformer coupling and photoelectric coupling (solid state relay). The output signal of this type of output circuit Without passing through the heating element RO, the sampling circuit will not be disturbed when sampling near the zero point of the grid waveform. The entire control circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com