Bar rust cleaning machine and rust cleaning method

A technology for descaling machine and bar material, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high production cost, energy consumption, bar material waste, etc., and achieve low production cost and low energy consumption , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

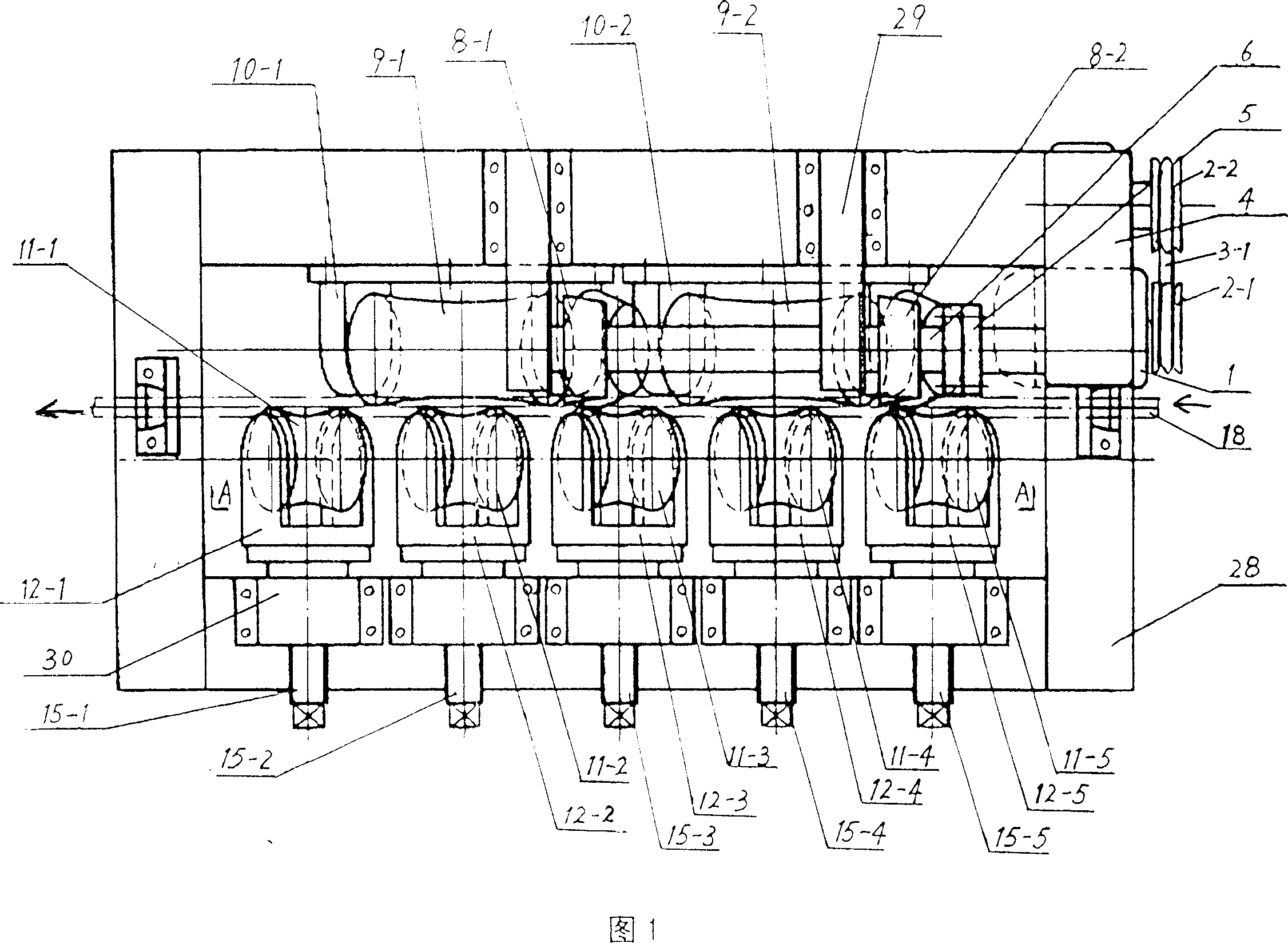

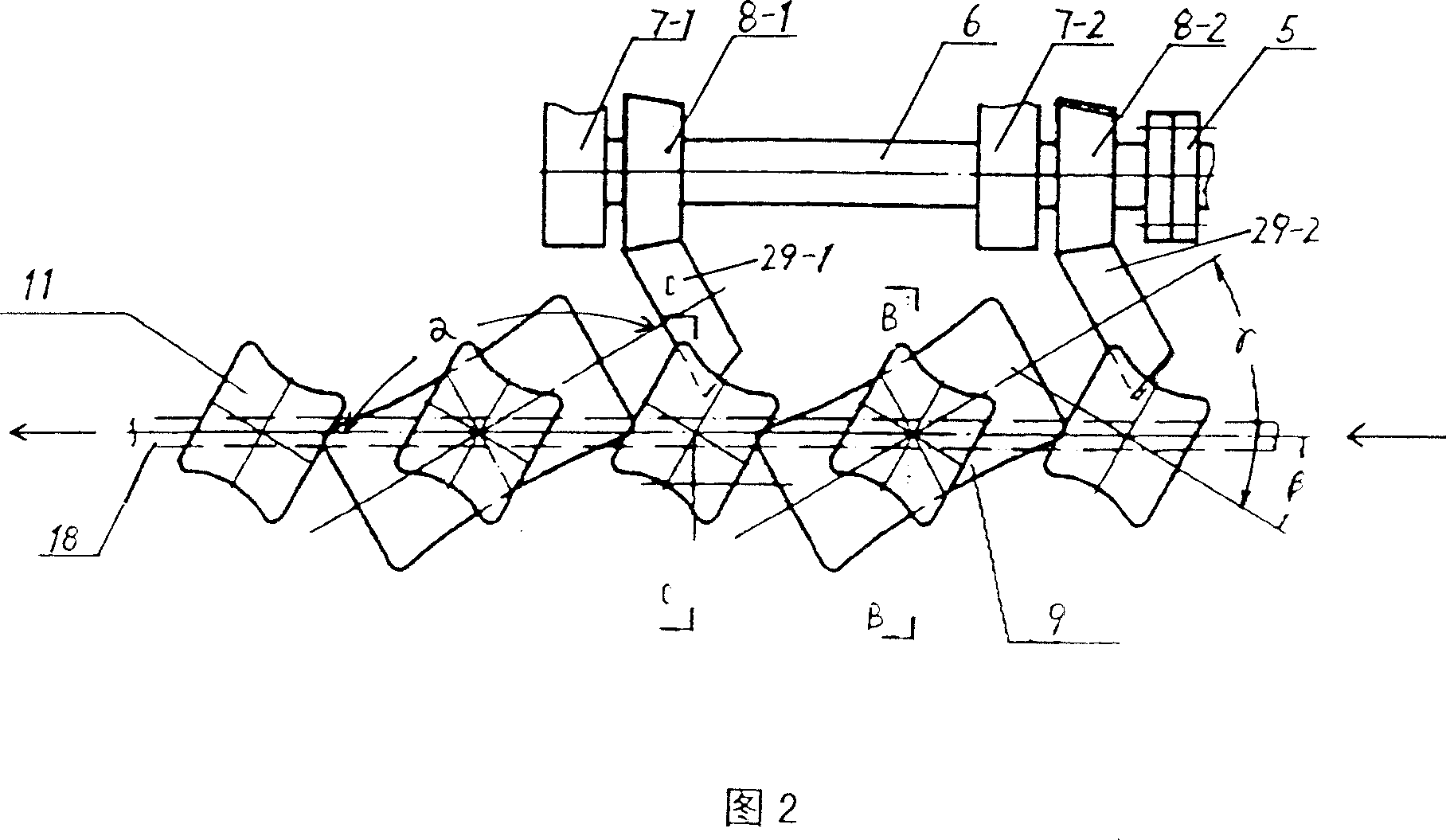

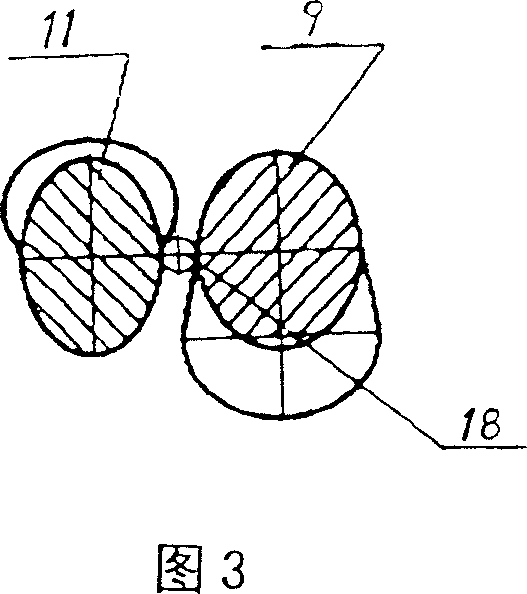

[0018] Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention comprises frame 28, power transmission mechanism 29, roller clamping conveying mechanism 30 and rolling brush mechanism 31, and frame 28 is provided with power transmission mechanism 29, roller clamp Tight conveying mechanism 30 and rolling brush mechanism 31, described power transmission mechanism 29 comprises motor 1, belt pulley 2-1 and 2-2, V-belt 3-1, speed reducer 4, coupling 5, transmission shaft 6, bearing 7 -1 and 7-2. The motor 1 is connected with the pulley 2-1, and the pulley 2-2 is dragged by the V-belt 3-1, the pulley 2-2 is connected with the speed reducer 4, and the speed reducer 4 is connected with the coupling 5, and the The transmission shaft 6 is installed in the bearings 7-1 and 7-2 and connected with the coupling 5.

[0019] The roller clamping conveying mechanism 30 includes large bevel gears 8-1 and 8-2, small bevel gears 29-1 and 29-2, main rolls 9-1 and 9-2, main roll stands...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com