Forming process of activated carbon carving

A molding process, activated carbon technology, applied in decorative arts, decorative structures, etc., can solve the problems of a large number of equipment and production time and energy consumption, complex production process, loss of adsorption capacity, etc., to achieve convenient production, ensure physical health, adsorption The effect of polluting gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

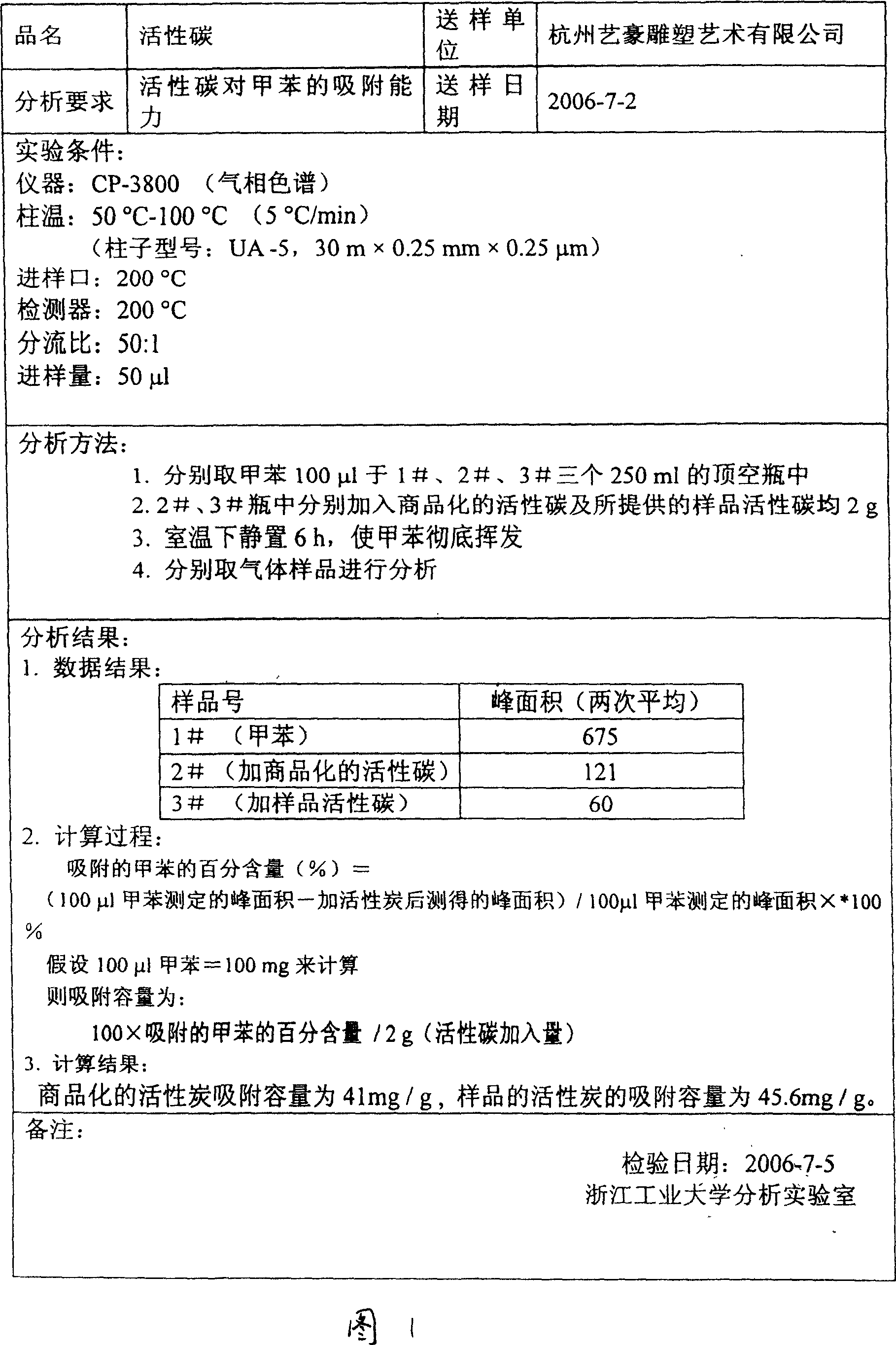

Embodiment 1

[0009] The molding process of activated carbon carving described in this embodiment is to mix and stir powdered activated carbon and water-soluble adhesive according to a certain ratio, and then put it into a molding mold to form and solidify. The water-soluble adhesive is a silicone acrylic emulsion. , when gluing and curing, a specified amount of defoamer (such as tributyl phosphate) can be added according to the curing requirements of the silicone acrylic emulsion. The ratio of the silicone acrylic emulsion to activated carbon can be 20 parts of the silicon acrylic emulsion added to 100 parts of powdered activated carbon. In the ratio of silicon-acrylic emulsion and activated carbon, the ratio of silicon-acrylic emulsion and activated carbon can also be 150 parts of silicon-acrylic emulsion added to 100 parts of powdered activated carbon. The shape formed and solidified in the forming mold can be directly used as a complete sculpture product, or it can be formed and solidifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com