Digital electro-hydraulic regulating system for steam turbine

A digital electro-hydraulic and regulating system technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large overshoot, insufficient self-tuning, asynchronous high and low pressure oil motors, etc., and achieve high reliability , flexible configuration mode, ensure the effect of advanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

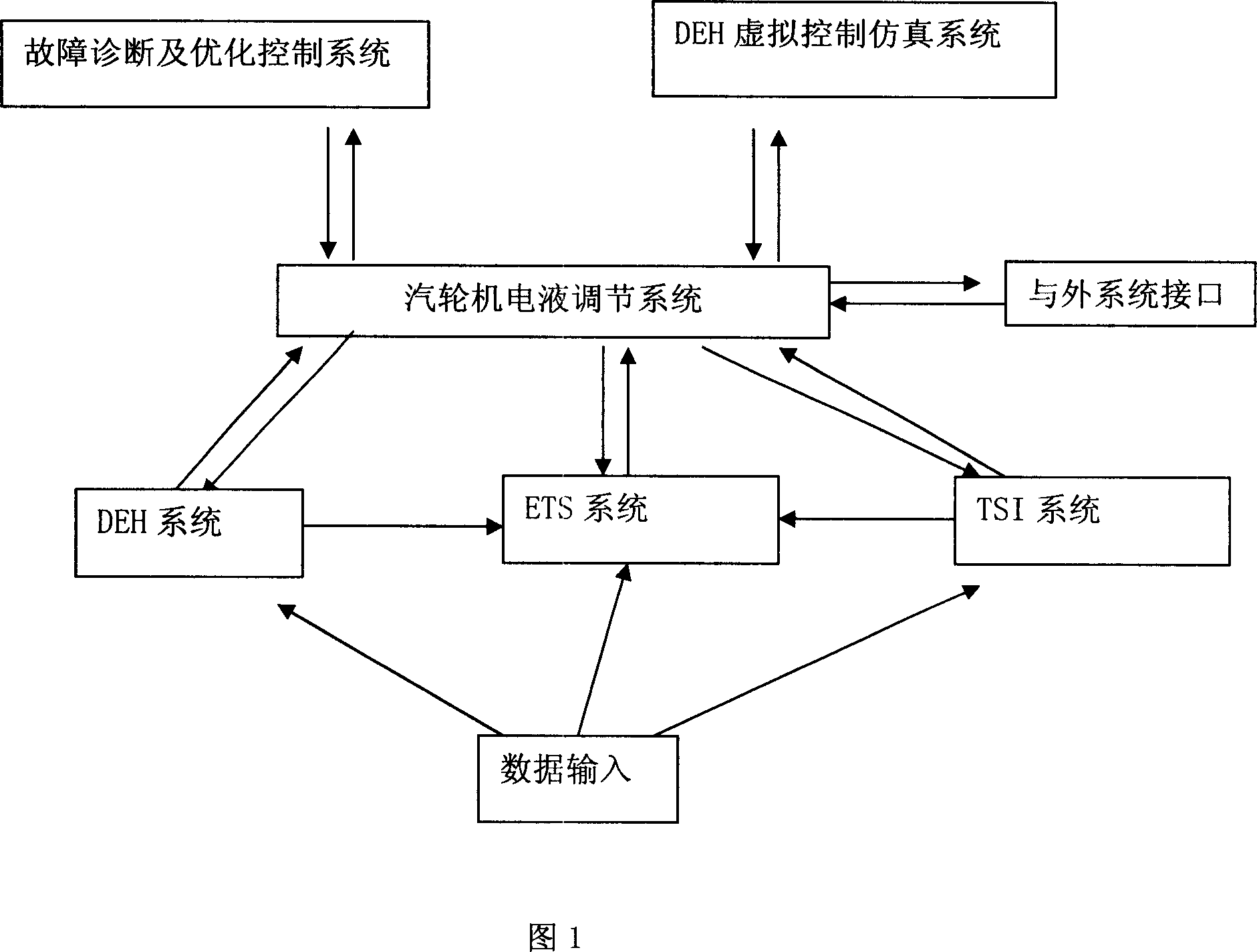

[0104] A steam turbine digital electro-hydraulic regulating system, including a distributed control system, a virtual control simulation system, a program control system, a monitoring information system, and a fault diagnosis and optimization control system; the distributed control system and the virtual control simulation system set at each control point of the unit and Program control system connection; according to the production simulation state, the virtual control simulation system with various data set by the user is connected with the program control system; the program control system will transfer the actual operating parameters of each unit from the distributed control system and the target value set in the database Compare and correct the operating parameters of each unit, so that the unit operates under the best parameters and working conditions, and at the same time transmit the data to the monitoring information system; the information monitoring system integrates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com