Moving phase grating mark and method for utilizing same in detecting image forming quality of photoetching machine

A technology of imaging quality and lithography machine, which is used in microlithography exposure equipment, photolithography process exposure devices, electrical components, etc. The problem is to overcome the incomplete detection, improve the detection accuracy of coma, and simplify the detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

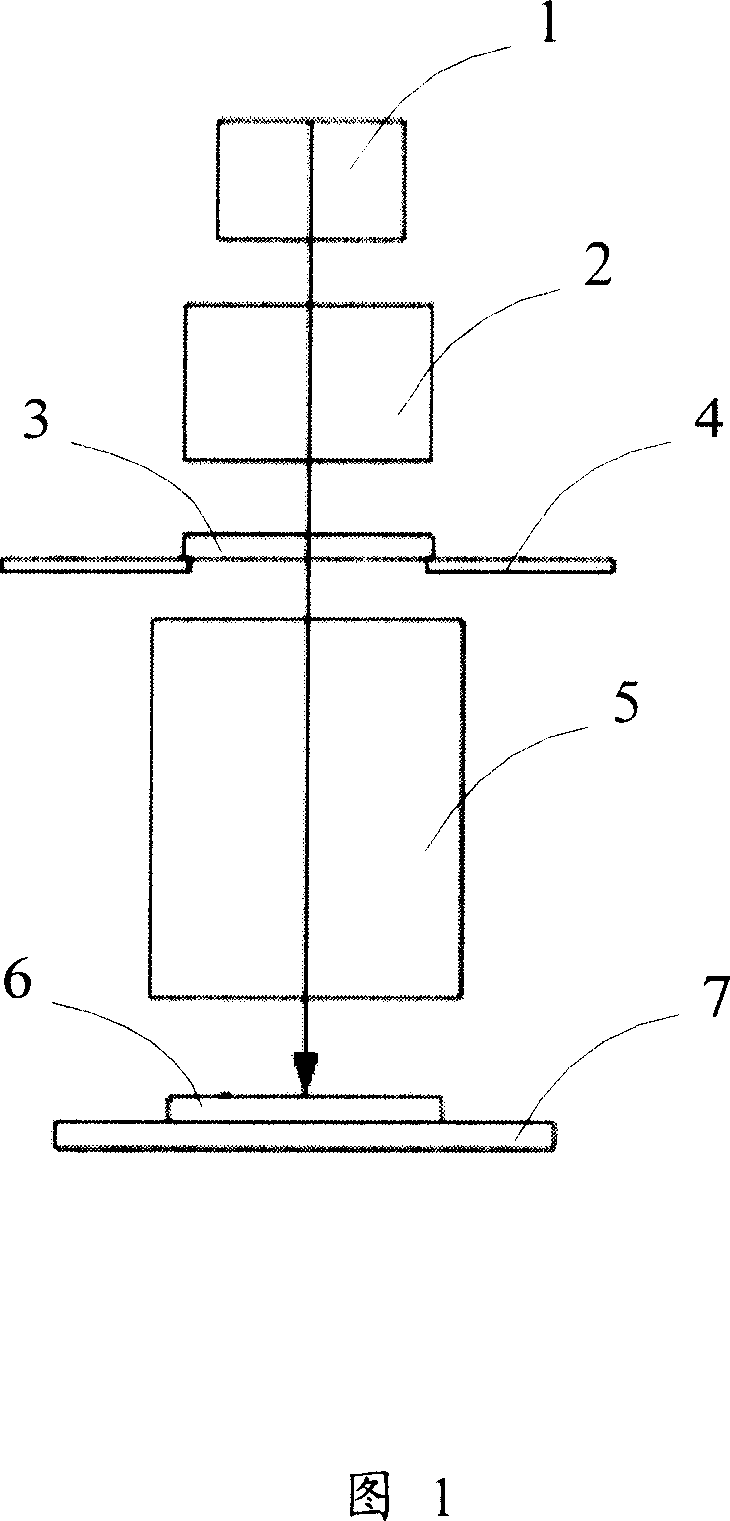

[0016] Please refer to Fig. 1, the lithography machine system of the present invention comprises a light source 1, an illumination system 2, a mask 3, a mask table 4 carrying a mask 3, a projection objective lens 5, a substrate 6 coated with photoresist and a workpiece carrying a substrate 6 Taiwan 7. Wherein, phase-shifting grating marks 31 are formed on the mask 3 . The light source 1 is used to generate an exposure beam. The illumination system 2 adjusts the light intensity distribution of the light beam emitted by the light source 1 , and the projection objective lens 5 images the phase-shifting grating marks 31 on the mask 3 on the substrate 6 .

[0017] The deep ultraviolet laser emitted by the light source 1 is irradiated on the mask 3 after passing through the illumination system 2, and the phase-shifting grating mark 31 on the mask 3 is imaged on the substrate 6 coated with photoresist through the projection objective lens 5, and finally the substrate 6 is post-baked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com