Industrial marsh gas producing process

A biogas and production method technology, applied in gas production bioreactors, biochemical instruments, biological sludge treatment, etc., can solve problems such as harsh operating environment, difficult sealing, and difficult collection of human feces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

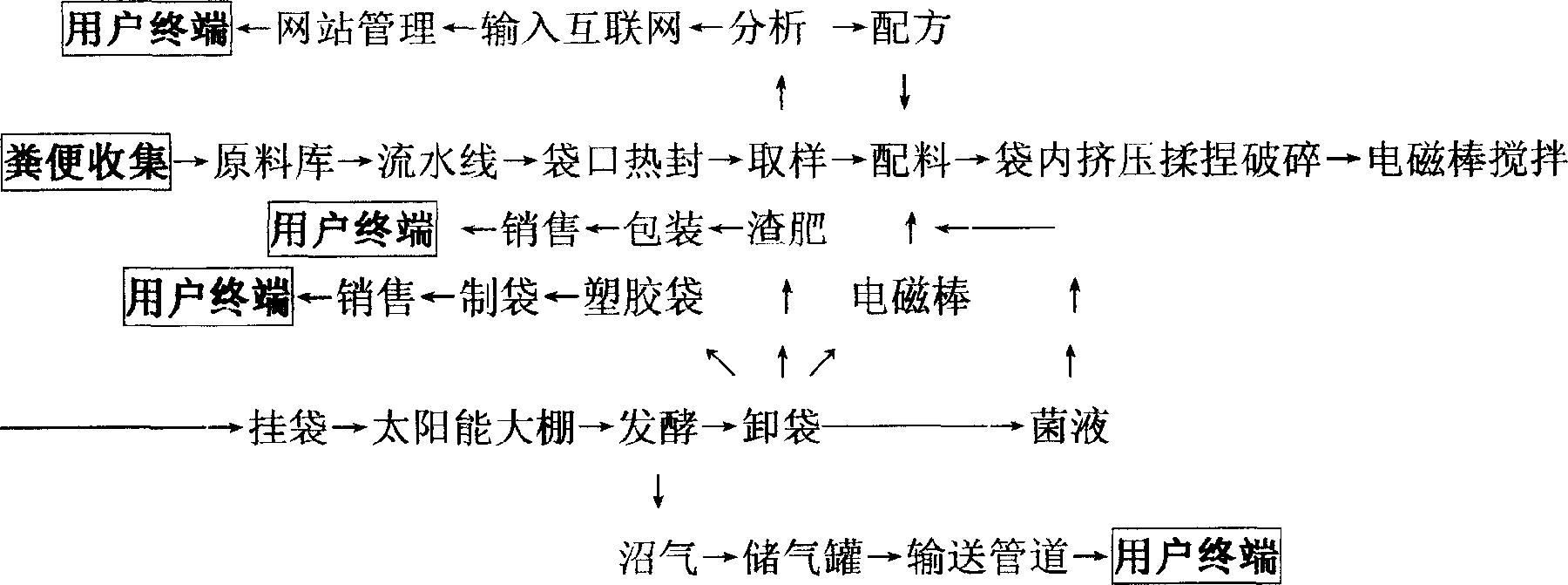

Method used

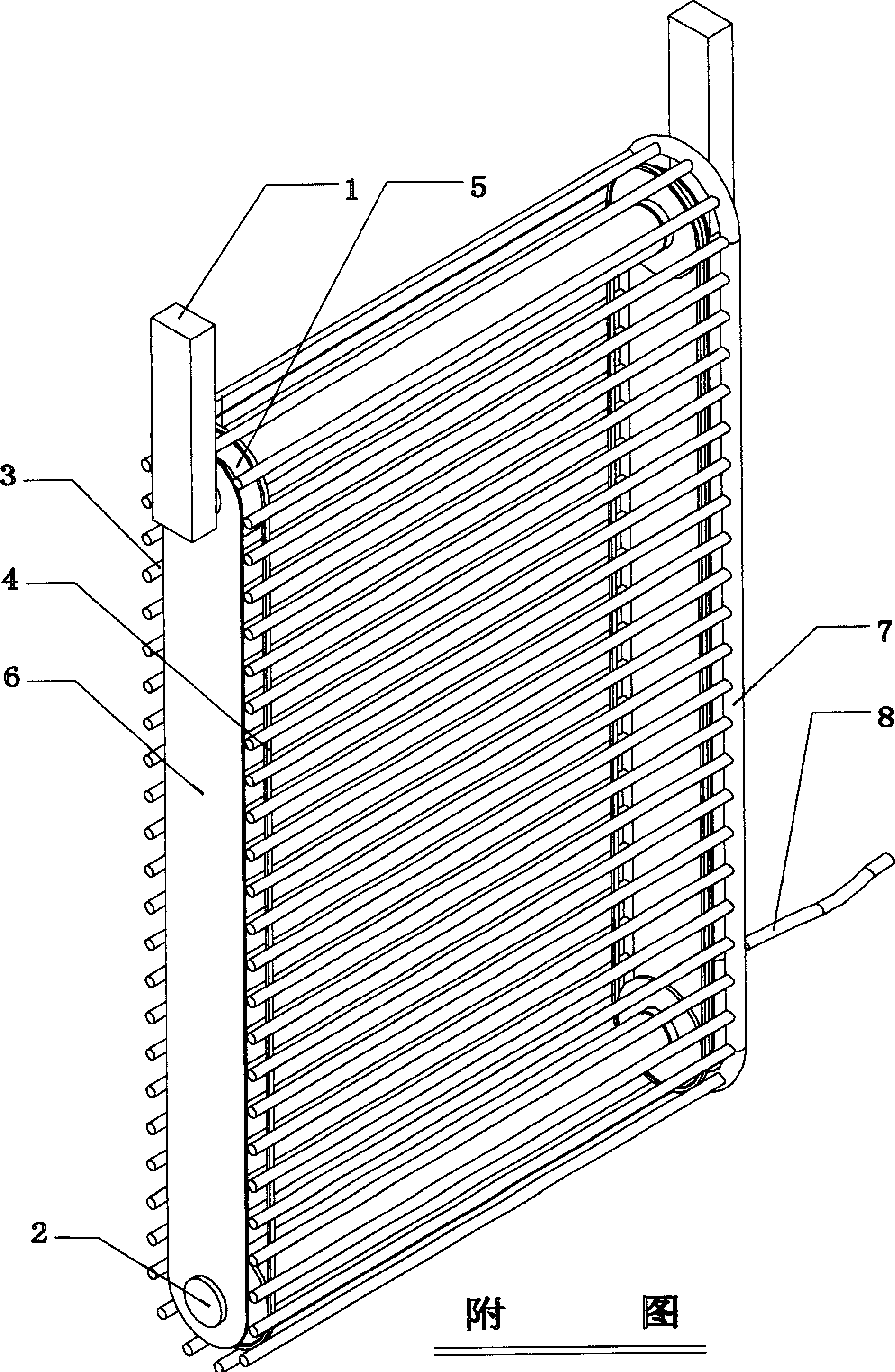

Image

Examples

Embodiment Construction

[0041] It is extremely easy to establish green ecological experimental communities or small towns in the form of low-cost housing to make people accept and get used to this method of excrement collection.

[0042] In order to attract people to live in, new concepts of transportation, construction, wind and solar energy utilization, and disaster prevention and avoidance are adopted in this green ecological experimental community or small town to completely improve people's living environment.

[0043] Here, people live in a safe and convenient environment where they know their health information every day and arrange their diets reasonably, without traffic accidents, traffic jams, traffic pollution and excrement pollution, without worrying about fires and earthquakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com