Manufacturing method for dry type grinding wheel of archaized brick and formula thereof

A manufacturing method, antique brick technology, applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of water consumption, easy pollution of water sources, customer dissatisfaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

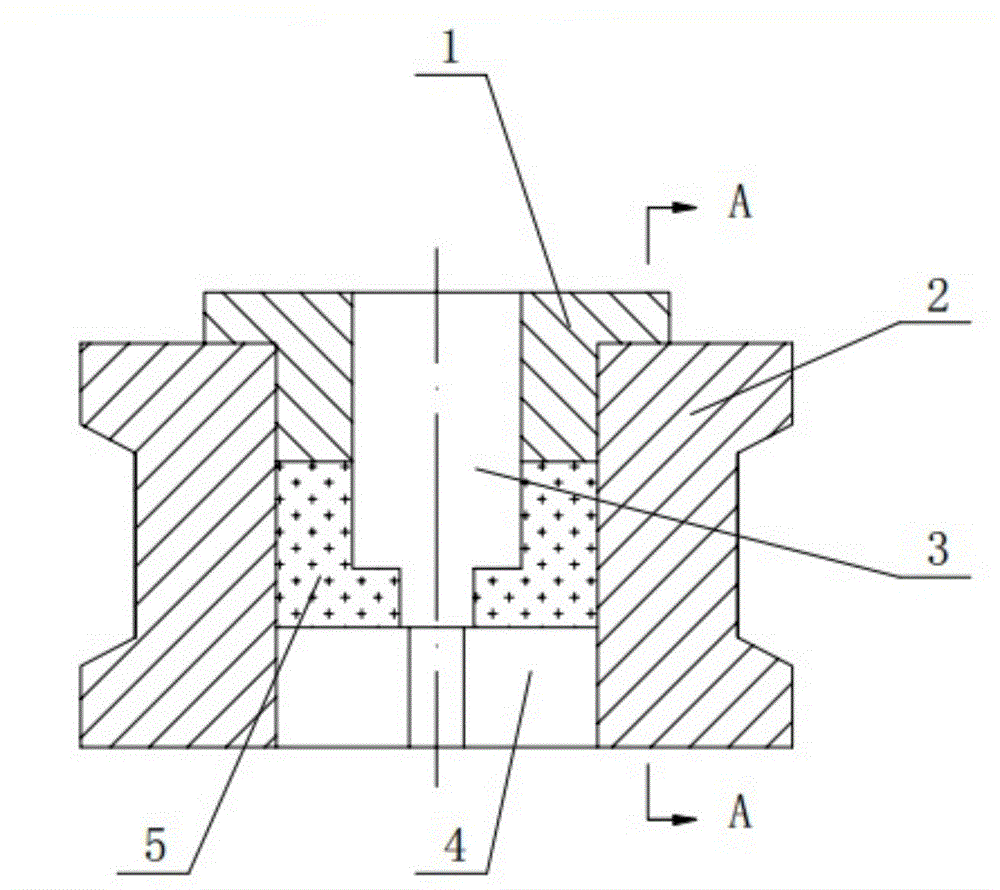

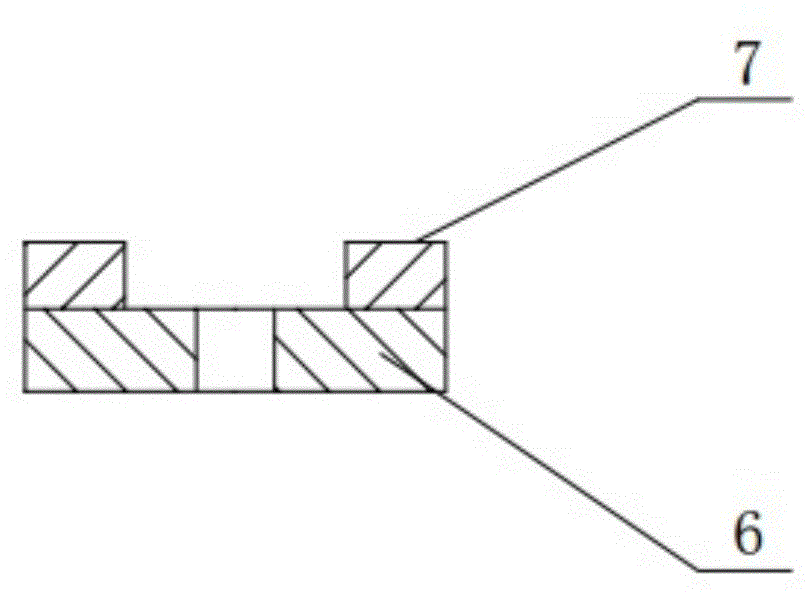

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

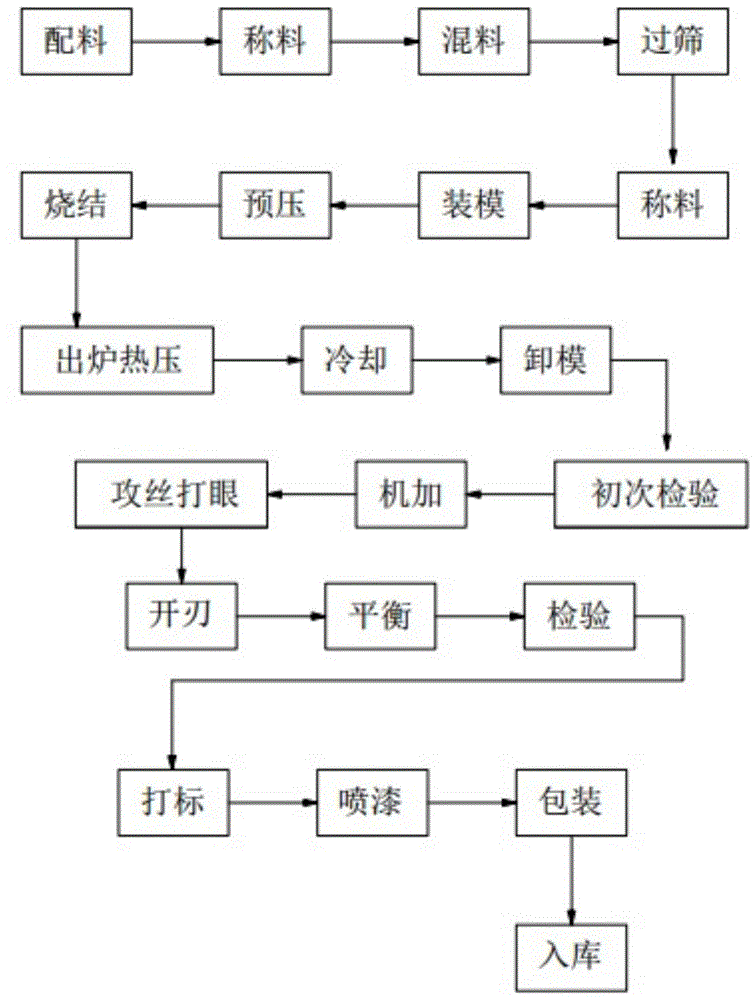

[0032] Such as Figure 1-Figure 3 Shown, a kind of antique brick dry-type grinding wheel manufacture method and formula thereof of the present invention, it adopts following technical scheme:

[0033] Its formula by weight is as follows: diamond 28-35g, silicon carbide 32-45g, copper powder superfine 50g, 300 mesh reduced iron powder 400g, 663 bronze powder 180g, special alloy powder 180g, cryolite 15g, light calcium carbonate 20g ;

[0034] Its manufacture adopts following method steps:

[0035] 1) Powder batching stage:

[0036] Step 1: Ingredients, diamond, silicon carbide, superfine copper powder, 300 mesh reduced iron powder, 663 bronze powder, special alloy powder, 15g of cryolite and 20g of light calcium carbonate;

[0037] Step 2: Weigh the ingredients, and weigh the above ingredients according to the following weight ratio according to the steps: 28-35g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com