Precision balance measuring instrument

A measuring instrument, high-precision technology, applied in the direction of measuring device, static/dynamic balance test, instrument, etc., can solve the problems of high interference and low precision, and achieve the effect of high measurement precision, wide measurement range and many types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

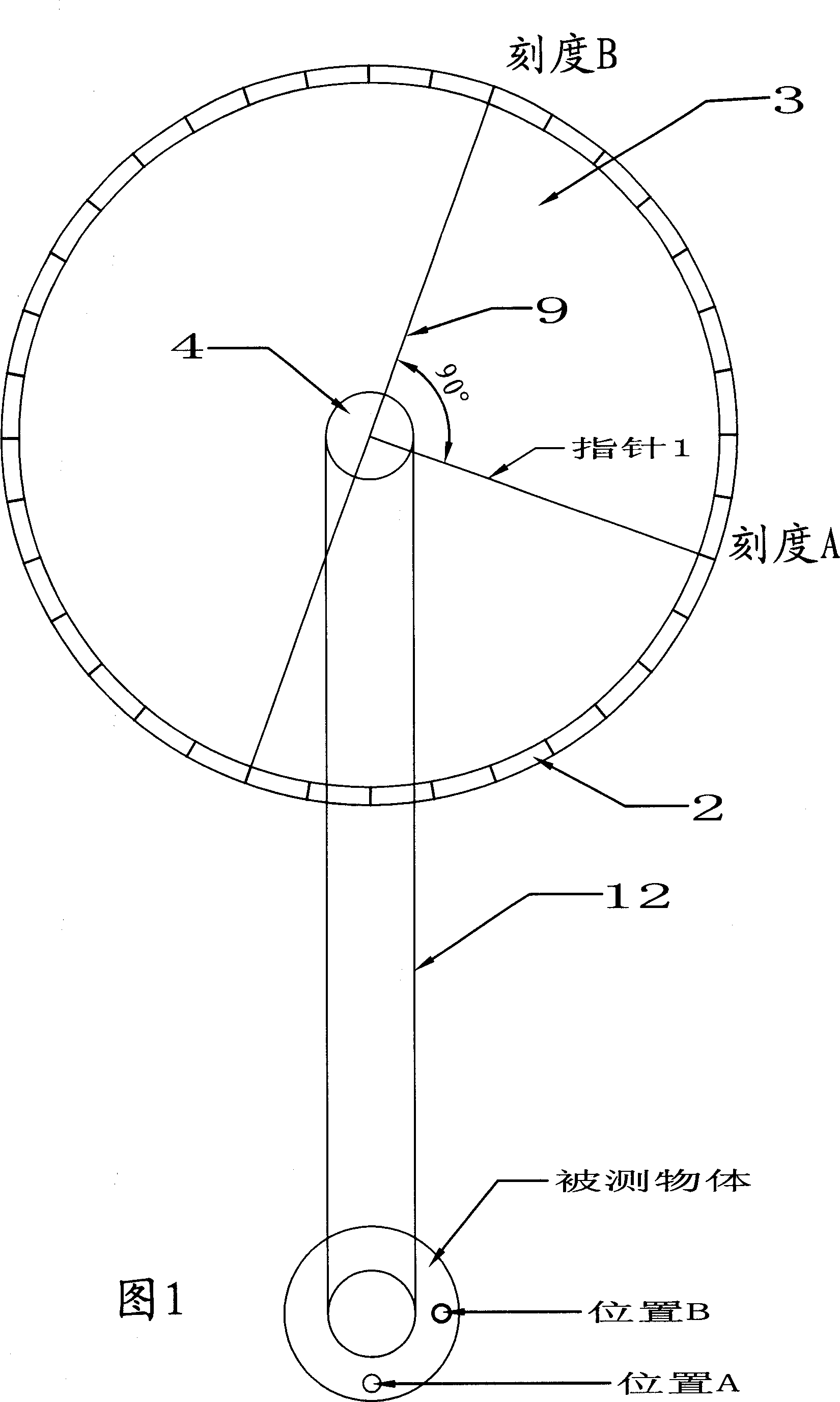

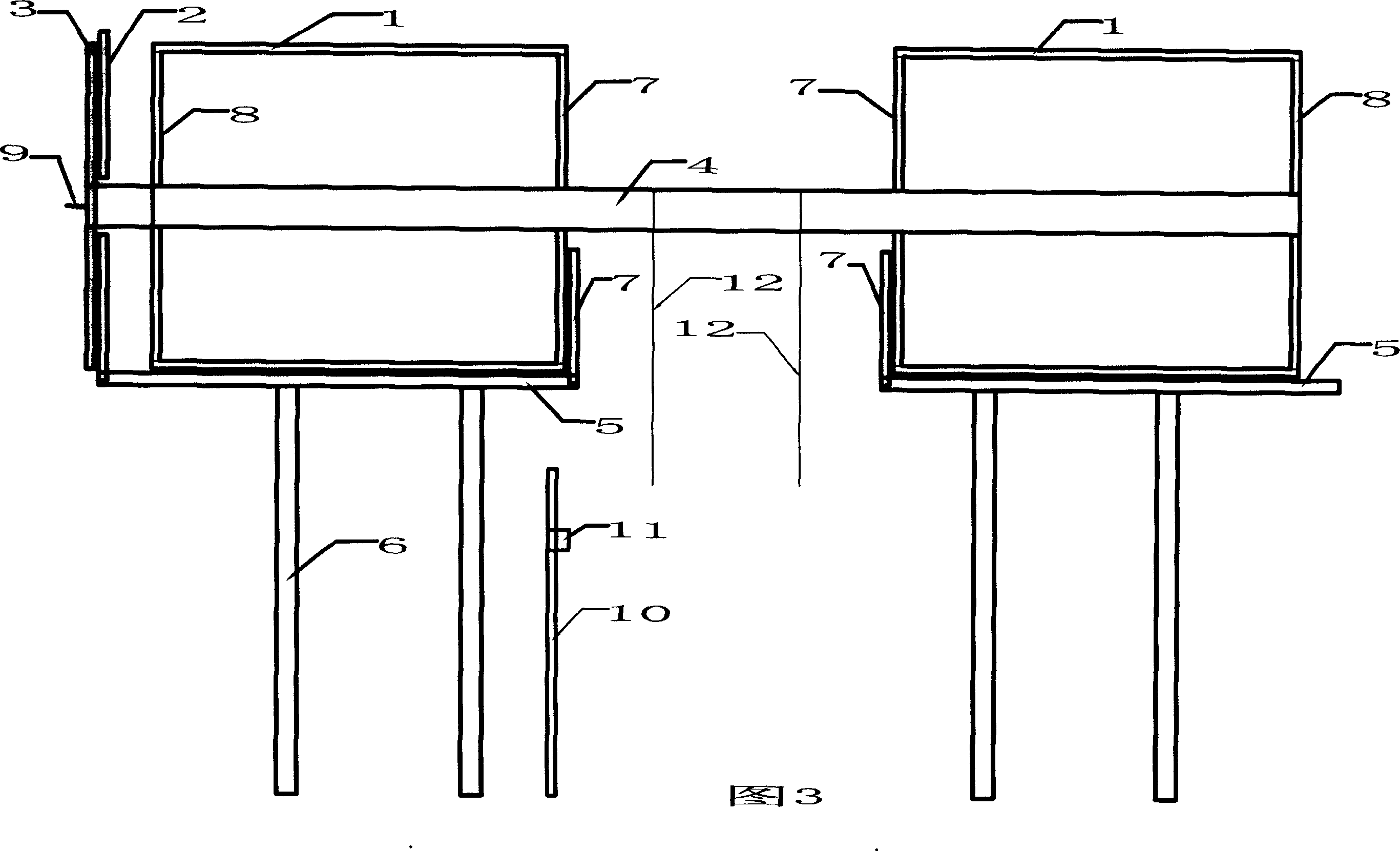

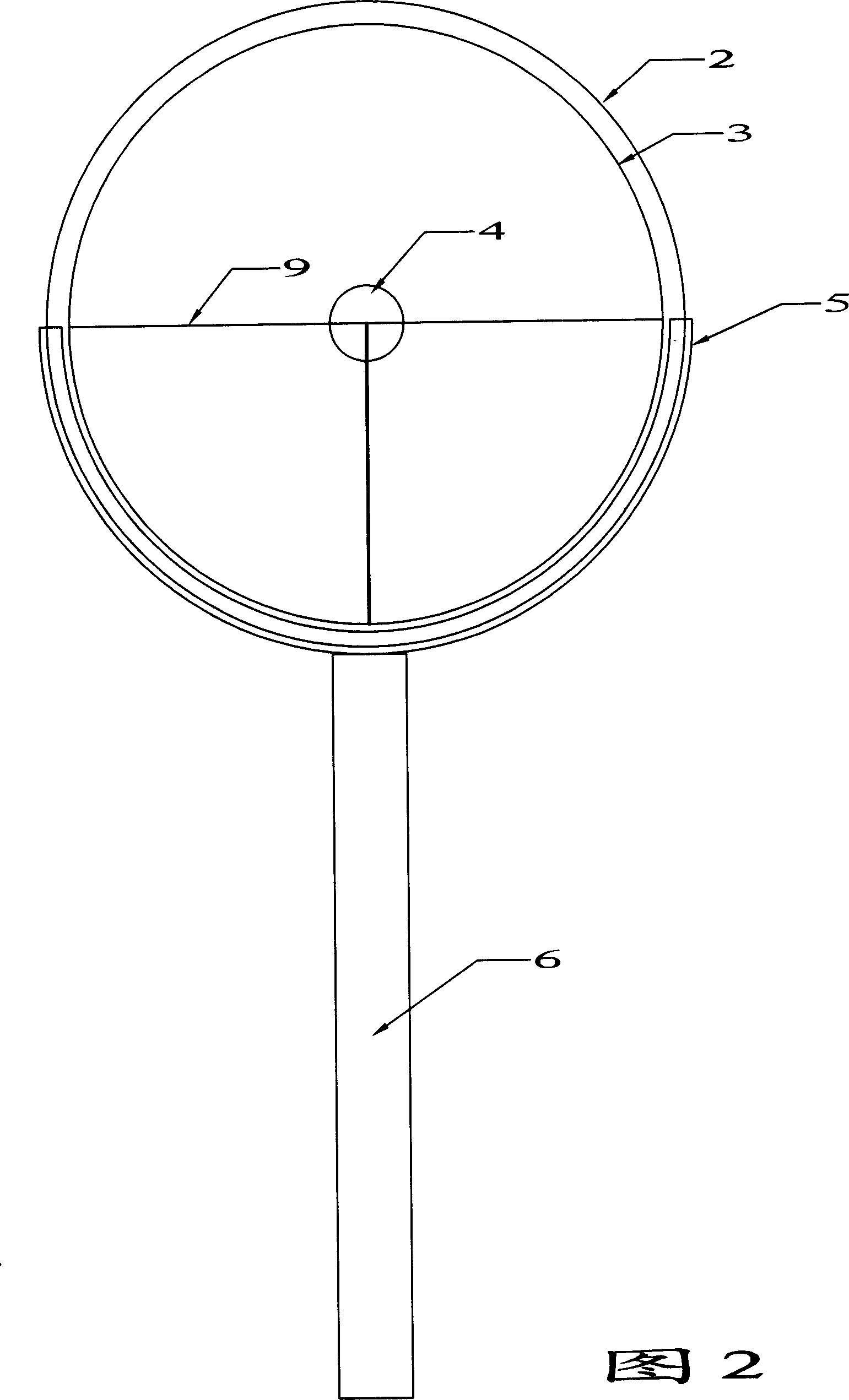

[0011] Embodiment one, in Fig. 3, the rare-earth strong magnet magnetic tube (1) of two uniform magnetic fields of the same size is connected together by the aluminum alloy circular tube (4) of 0.5 centimeter of tube wall thickness, wherein two magnetic tubes ( 1) The axis line of the aluminum alloy round tube (4) is on the same horizontal straight line, and is parallel to the axis line of the two semicircular magnetic slots (5) directly below, and the magnetic cylinder (1) is placed In the slightly larger magnetic groove (5), the polarity of the outer side of the magnetic cylinder (1) is the same as that of the inner side of the magnetic groove (5) and they are relatively opposite to each other, thus forming a suspension component. The magnetic cylinder (1) can be placed in the magnetic groove ( 5) Roll freely without resistance. One end of the aluminum alloy round tube (4) stretches out the bottom seal plate (8) of the magnetic cylinder and fixes an indicator plate (3) at th...

Embodiment 2

[0013] In the second embodiment, the rare earth ferromagnetic material of the magnetic cylinder and the magnetic groove is replaced with an electromagnet or a superconducting magnet. Others are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com