Method for preparing multiple high-purity anisotropic gold nano particle

A gold nanoparticle and anisotropic technology, which is applied in the field of high-purity anisotropic gold nanoparticles and its preparation, can solve the problems of low purity and low yield of anisotropic gold nanoparticles, and achieves high purity and equipment. Low requirements and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

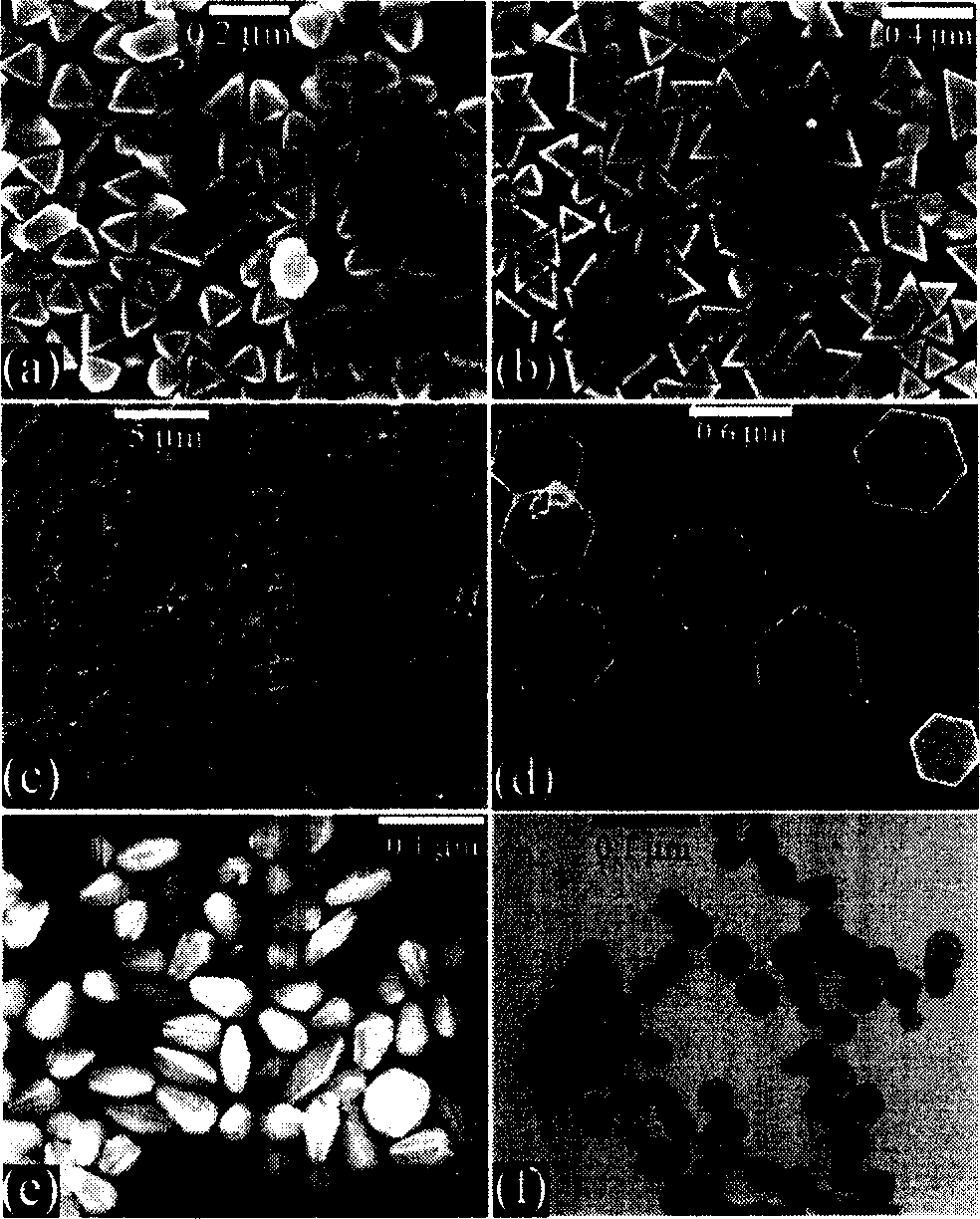

[0010] Embodiment 1: the preparation of regular octahedral gold nanoparticles (Fig. 1a), its steps are:

[0011] (1) Prepare 60 ml of C in a covered reaction vessel 6 h 5 o 7 Na 3 2H 2 O (0.5wt%) aqueous solution (6.5wt%) / PVP (K30, 7.5wt%) / n-amyl alcohol (86wt%) multiple solution system;

[0012] (2) 1.5 ml HAuCl 4 4H 2 Add O (0.024M) ethanol solution into the system under stirring, continue to stir for 5 minutes, and then put it into a constant temperature box for heat treatment at 95°C for 24 hours;

[0013] (3) centrifuging the heat-treated reaction solution to obtain octahedral gold nanoparticles.

Embodiment 2

[0014] Embodiment 2: the preparation of acicular gold nanoparticles (Fig. 1e), the steps are:

[0015] (1) Prepare 60 ml of C in a covered reaction vessel 6 h 5 o 7 Na 3 2H 2 O (0.5wt%) aqueous solution (3wt%) / PVP (K30, 2.7wt%) / n-amyl alcohol (94.3wt%) multiple solution system;

[0016] (2) 1.5 ml HAuCl 4 4H 2 Add O (0.024M) ethanol solution into the system under stirring, continue to stir for 5 minutes, and then put it into a constant temperature box for heat treatment at 95°C for 24 hours;

[0017] (3) centrifuging the heat-treated reaction solution to obtain needle-shaped gold nanoparticles.

Embodiment 3

[0018] Embodiment 3: the preparation of gold nanoparticles, its steps are:

[0019] (1) Prepare 60 ml of C in a covered reaction vessel 6 h 5 o 7 Na 3 2H 2 O (0.05wt%) aqueous solution (7wt%) / PVP (K30, 10wt%) / n-amyl alcohol (83wt%) multiple solution system;

[0020] (2) 1.5 ml HAuCl 4 4H 2 Add O(2M) ethanol solution into the system under stirring, continue to stir for 30 minutes, and then put it into a constant temperature box for heat treatment at 100°C for 48 hours;

[0021] (3) centrifuging the heat-treated reaction solution to obtain needle-shaped gold nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com