Diesel engine thin-wall cylinder casing and its mfg. method

A diesel engine and cylinder liner technology, which is applied in the field of cylinder liner manufacturing, can solve the problems of different properties, occupying the cooling medium circulation channel space, and the undiscovered technical solution cylinder liner requires nodular cast iron varieties, etc., to achieve overall performance improvement and guarantee The effect of reliability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

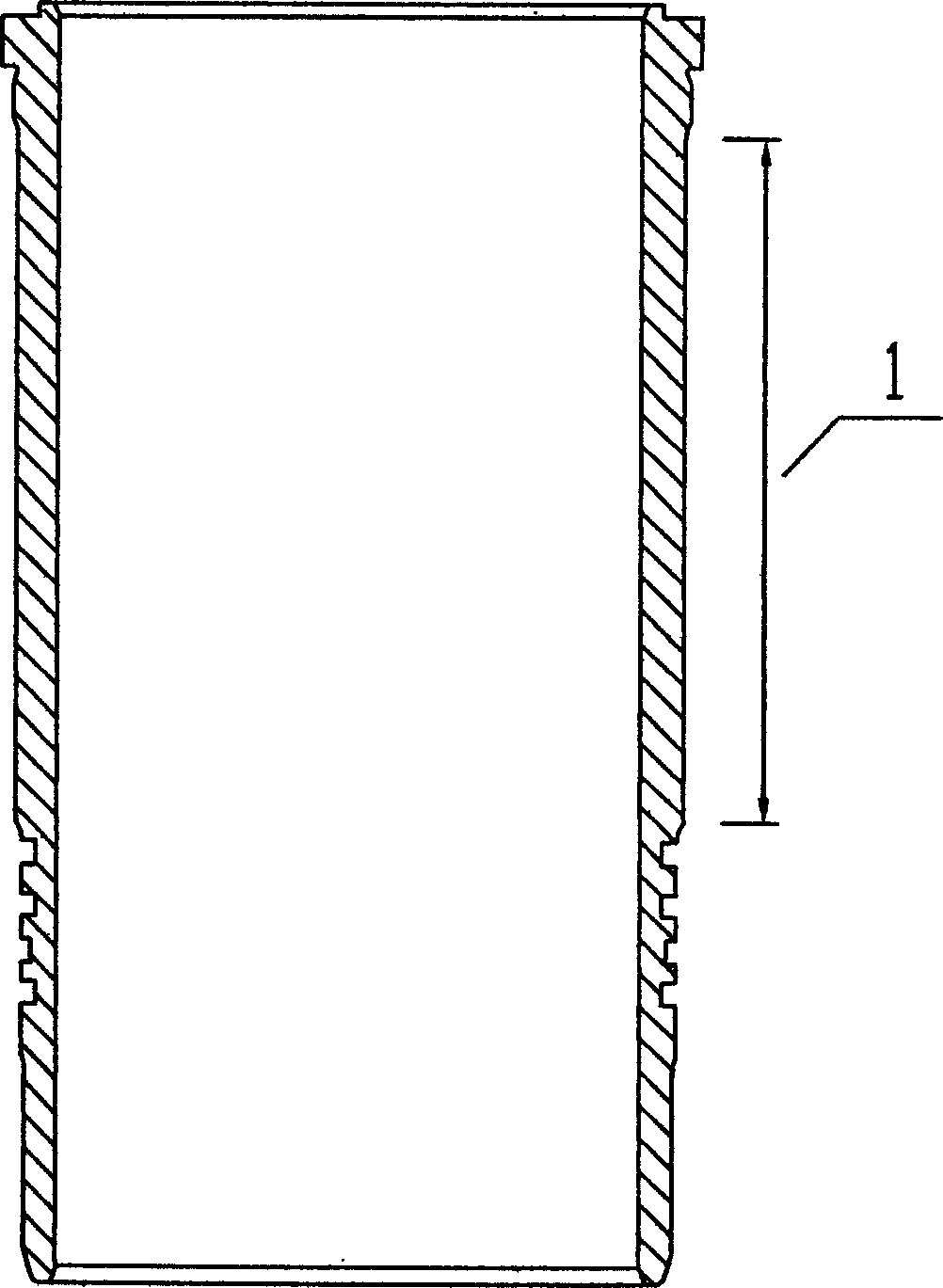

[0029] Embodiment 1: As shown in the accompanying drawings, the wall thickness of the cylinder liner 1 is 6.0 mm, the material of the cylinder liner body is pearlitic ductile iron, and the pearlite content in the pearlitic ductile iron is 90%.

[0030] The cylinder liner with an inner hole of Ф105mm, according to the reliability requirements, uses an alloy cast iron cylinder liner, and the minimum wall thickness should be above 6.5mm. In the case of the limitation of the cylinder center distance, the cooling channel is greatly reduced, and the wall thickness is 6.0mm. The pearlitic ductile iron cylinder liner has passed the 1000-hour durability test in the laboratory, and the performance of the diesel engine meets the design requirements, and the water temperature is stable within the design range.

Embodiment 2

[0031] Embodiment 2: As shown in the accompanying drawings, the wall thickness of the cylinder liner 1 is 5.0 mm, the material of the cylinder liner body is pearlitic ductile iron, and the pearlite quantity in the pearlitic ductile iron is 80%.

[0032] For cylinder liners with an inner hole of Ф110mm, alloy cast iron cylinder liners are used according to reliability requirements, and the minimum wall thickness should be above 6.5mm. If used in high-power or marine diesel engines, the minimum wall thickness of cylinder liners should be above 7.5mm. When the cylinder center distance is limited and the wall thickness of the alloy cast iron cylinder liner cannot guarantee the reliability requirements, the pearlitic ductile iron liner is used with a wall thickness of 5.0mm. After 1000 hours of durability test in the laboratory, the performance of the diesel engine meets the design requirements and the water temperature is stable. within the design limits.

[0033] After the test, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com