Pouring-basket plug-rod with continuous temperature measuring function

A temperature measurement function, continuous casting tundish technology, applied in the fields of measurement and detection, metallurgical equipment accessories, can solve the problems of increasing temperature measurement costs, etc., and achieve the effect of saving costs, low maintenance costs, and low temperature measurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

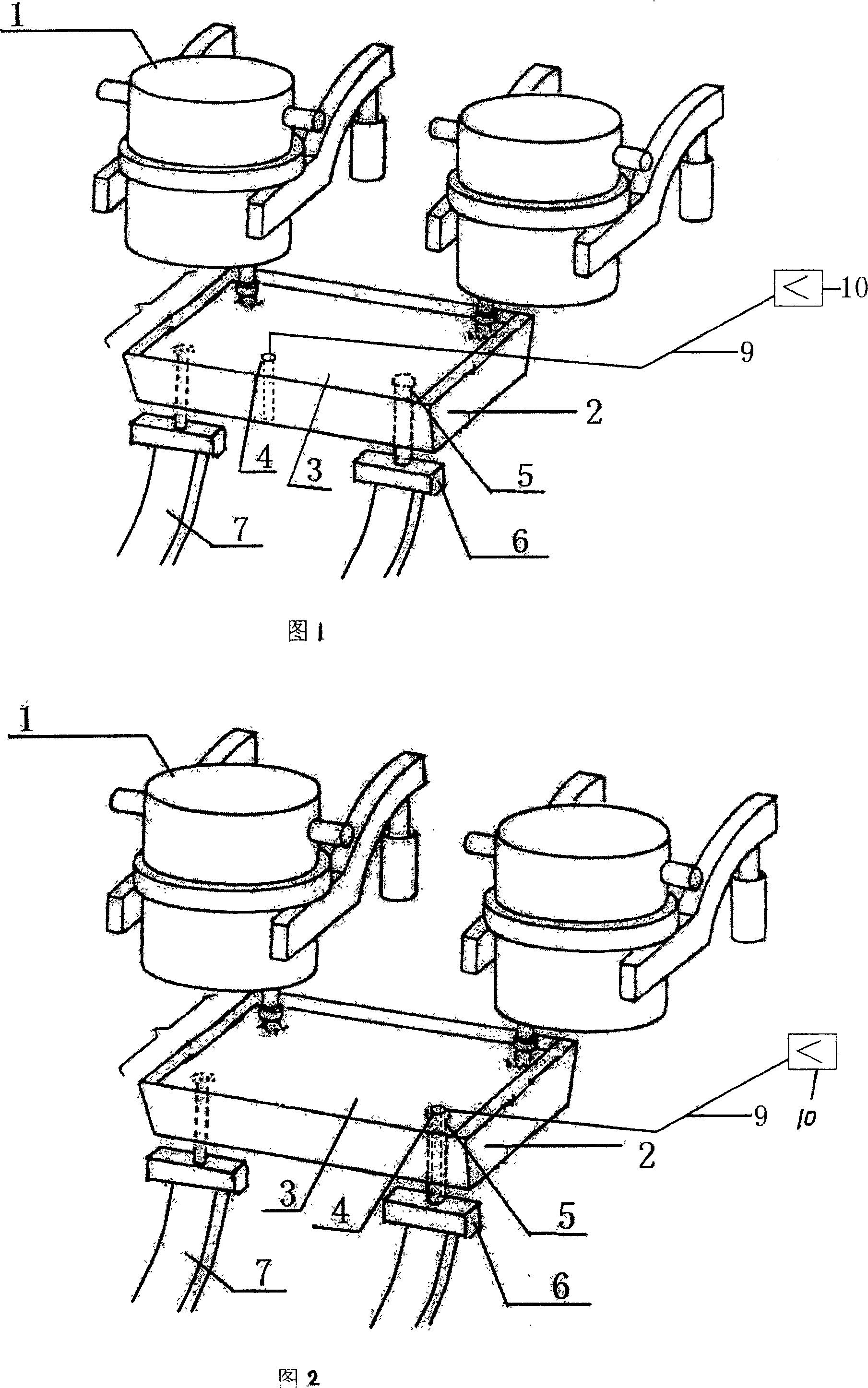

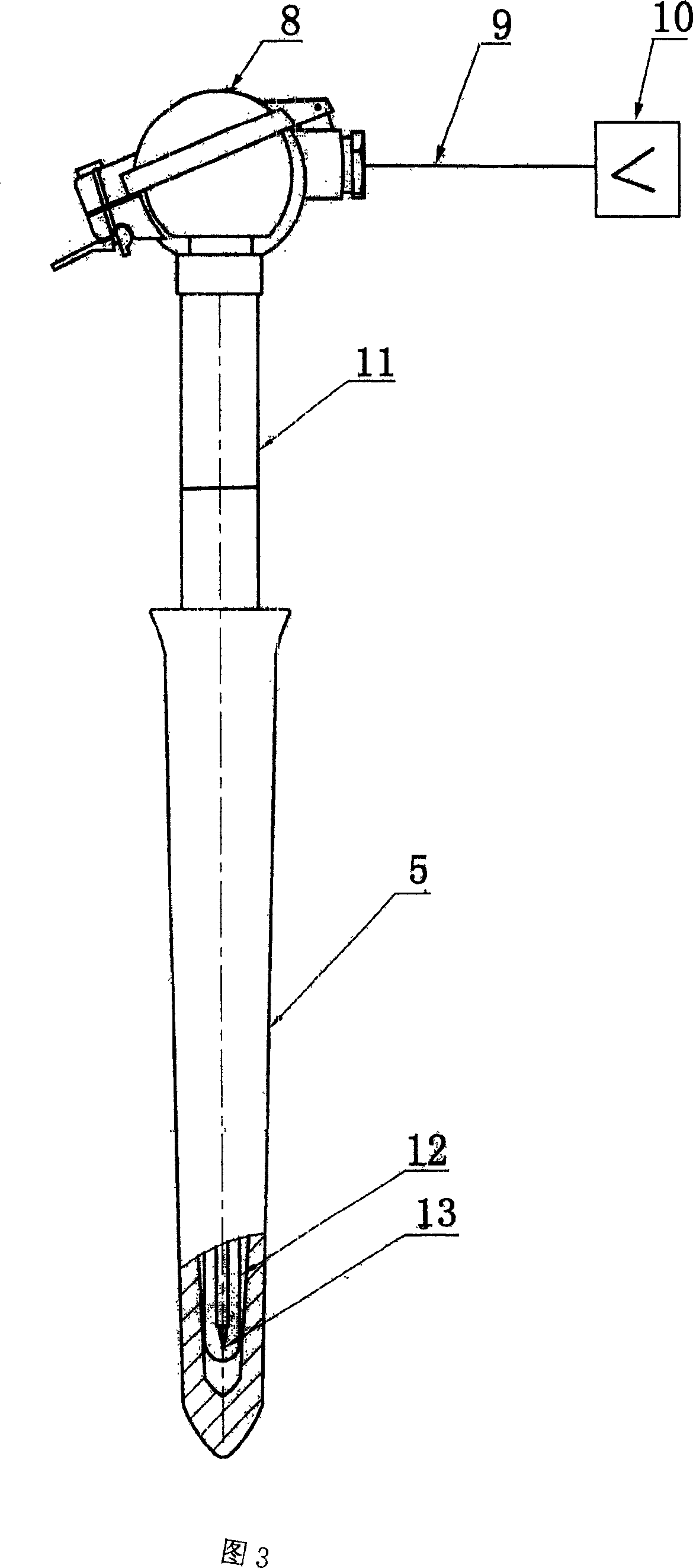

[0027] Embodiment 1: as shown in Figure 2 and Figure 3, the structure of the present invention: a temperature measuring device is installed on the tundish plug rod 5, and the temperature measuring device is a thermocouple temperature measuring device in this example, as shown in Figure 3, It includes a thermocouple 13, a compensation wire 9 and a temperature measuring instrument 10. The thermocouple 13 is connected to the temperature measuring instrument 10 through the compensation wire 9. The thermocouple 13 is equipped with a protection tube 12, which is placed in the stopper rod 5. The protection tube 12 passes through the clamp The holding pipe 11 is connected with the junction box 8 . Its thermocouple 13 is S type, or B type, or W3 type, or W5 type thermocouple, adopts S type in this example.

[0028] When in use, just move the installation bracket of the thermocouple temperature measuring device above the stopper rod 5 and get final product. The present invention can be...

Embodiment 2

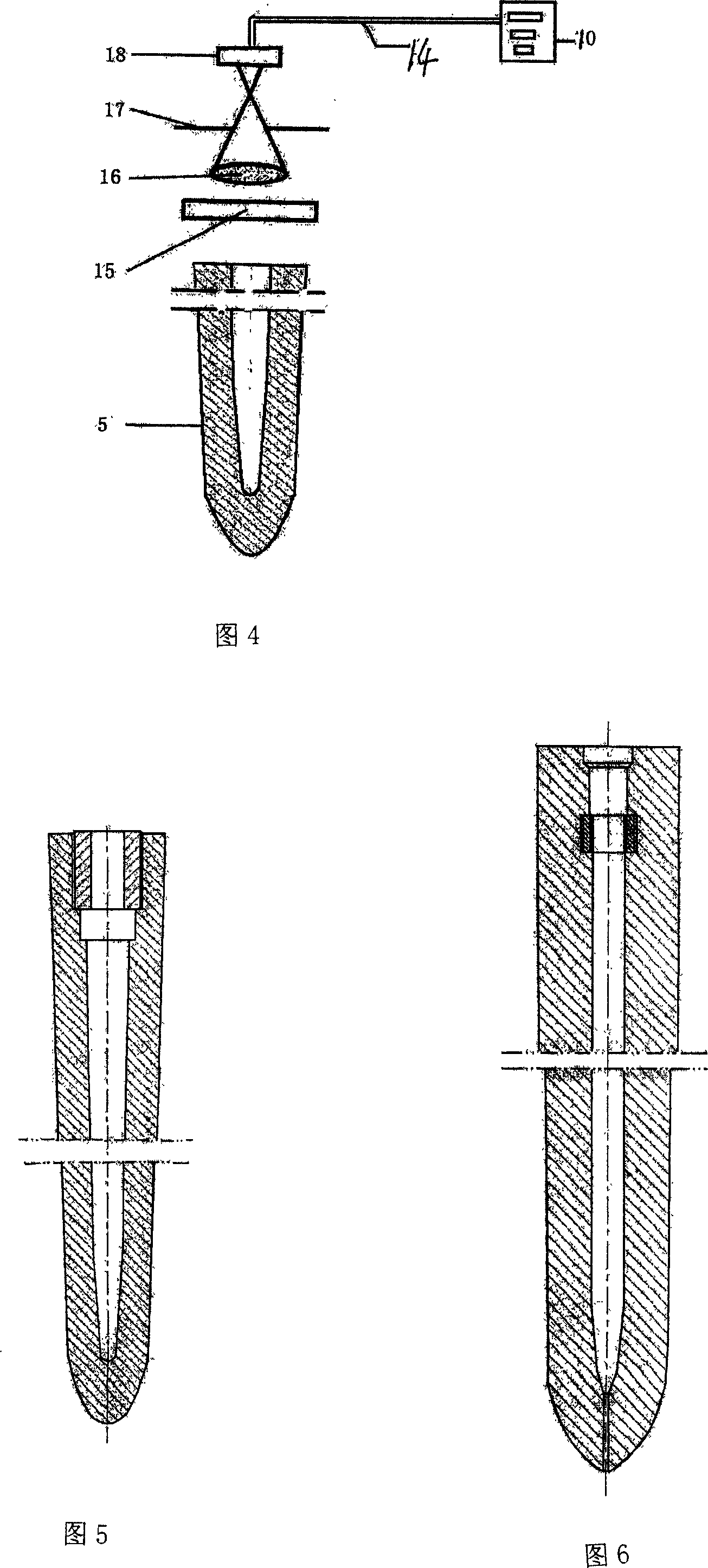

[0029] Embodiment 2: as shown in Figure 2 and Figure 4, the structure of the present invention: a temperature measuring device is installed on the continuous casting tundish plug rod 5, and the temperature measuring device is a radiation temperature measuring device in this example, as shown in Figure 4 shown, including a lens 16, an adjustable light bar 17, a detector 18, an optical fiber 14, and a temperature measuring instrument 10. The detector 18 is connected to the temperature measuring instrument 10 through an optical fiber 14, and the adjustable light bar 17, The lens 16 and the protective glass 15 are placed above the stopper rod 5 . In this example, the stopper rod is a stopper rod with a small hole at the top, as shown in Figure 6.

[0030] During use, as long as the radiation temperature measuring device is aimed at the upper opening of the stopper rod 5 . The light barrier 17 is adjusted so that the infrared light beam inside the stopper rod 5 is focused on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com