Alignment mark and its producing method

A technology for alignment marks and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, photo-plate-making process of patterned surface, photo-plate-making process exposure device, etc., can solve the problem of energy not being effectively utilized, and achieve compact structure, Effect of small grating line width and improved alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

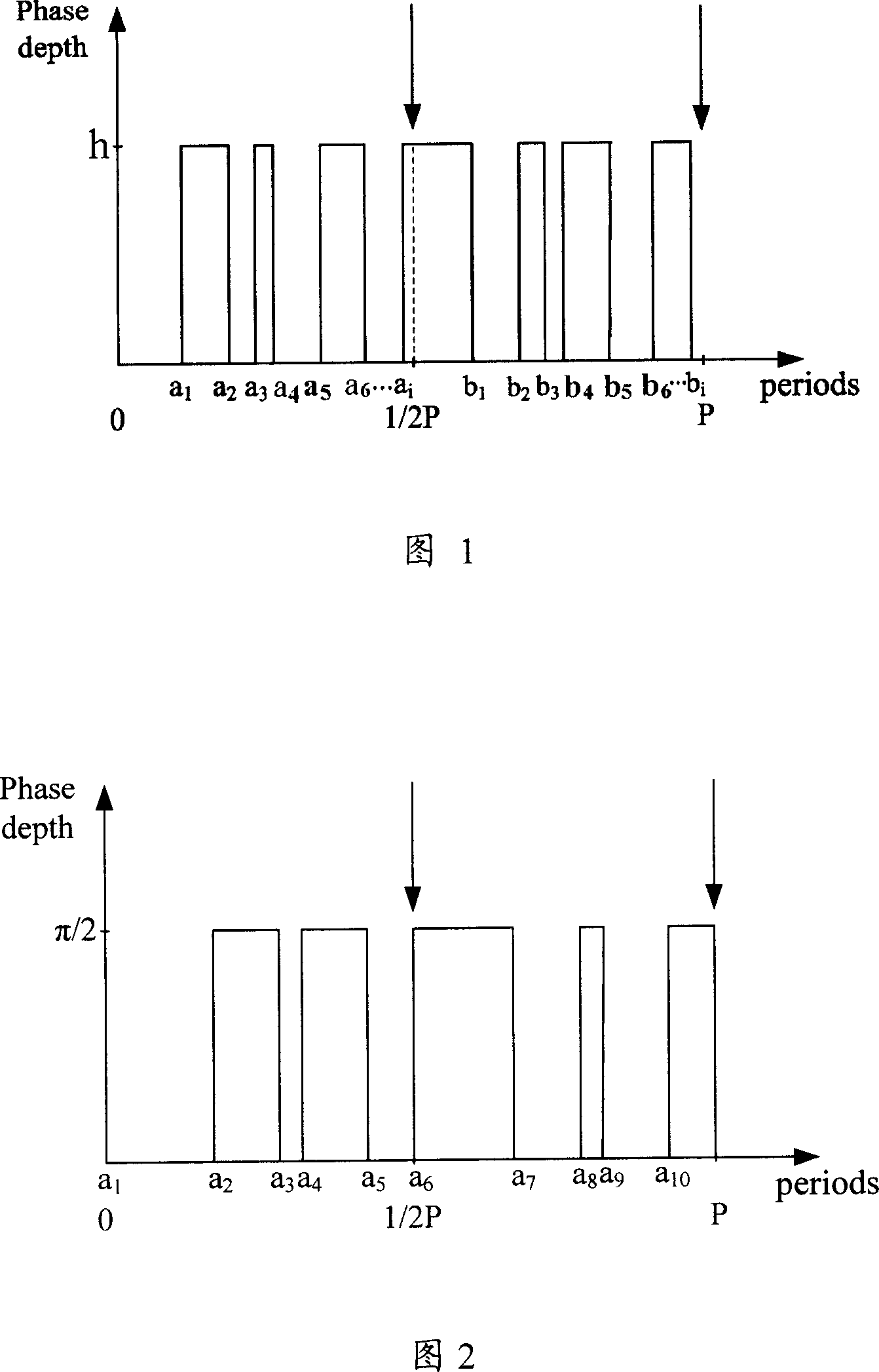

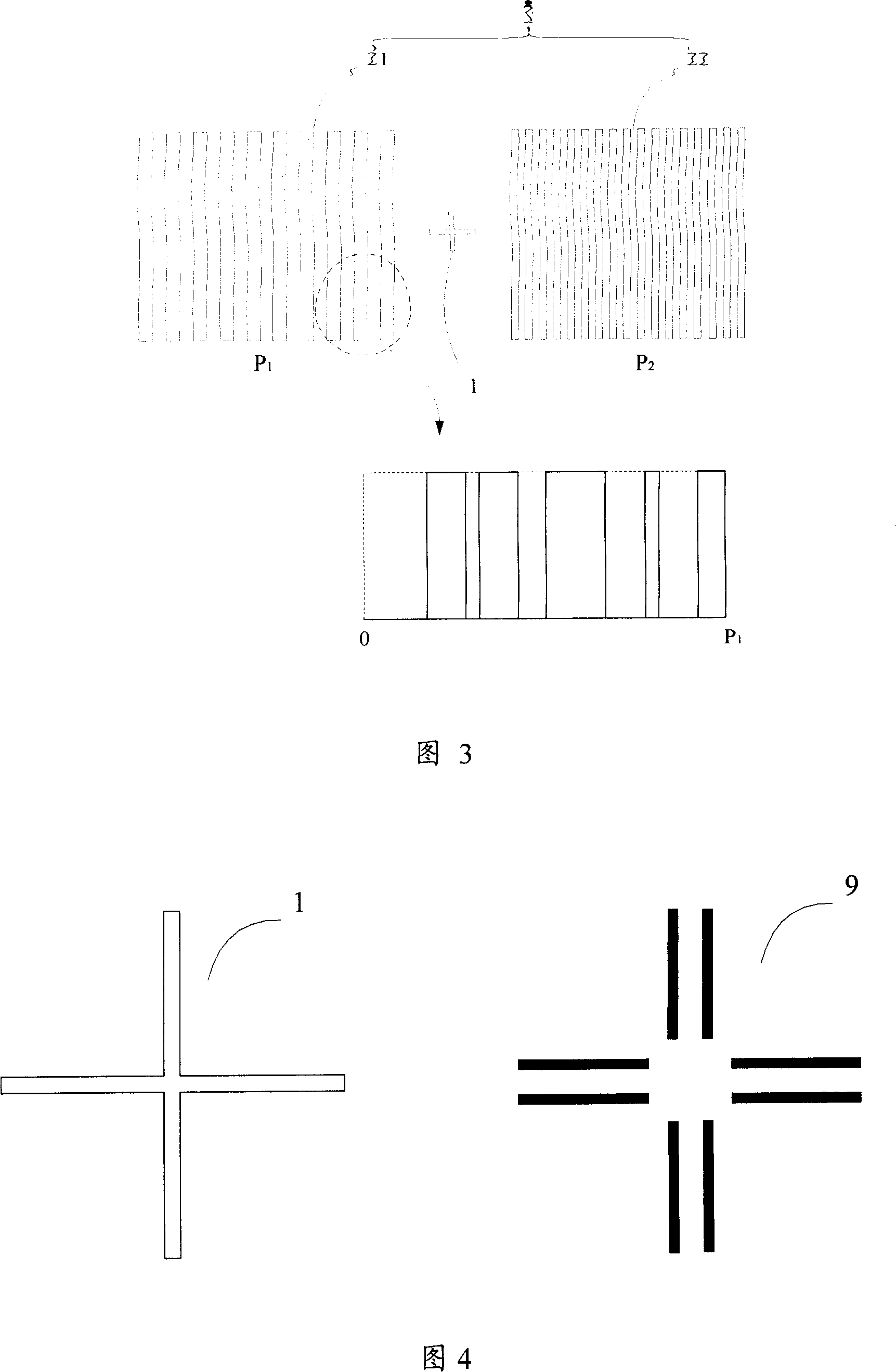

[0038] FIG. 1 is a high-order diffracted light-enhanced subdivision structure of the alignment mark of the present invention. The basic principle of the high-order diffractive light-enhanced subdivision structure is based on the reflection-type Dammann grating principle of an even-numbered array.

[0039] The Damman grating is a phase grating with a special aperture function, and the Fraunhofer diffraction pattern (Fourier spectrum) produced by it on the incident light wave is a certain number of equal-intensity spots. The Damman grating can transfer the energy of the zero-order diffraction spot to the positive and negative orders of the edge. It is a Fourier transform beam splitter with high diffraction efficiency, and the light intensity uniformity of the spot array i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com