Alignment mark and its imaging optical system and imaging method

A technology for alignment marks and optical systems, applied in the field of optical systems, can solve problems affecting alignment accuracy, quasi-signal intensity attenuation, and diffraction efficiency reduction, and achieve the goals of improving alignment accuracy, strong process adaptability, and increasing capture range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

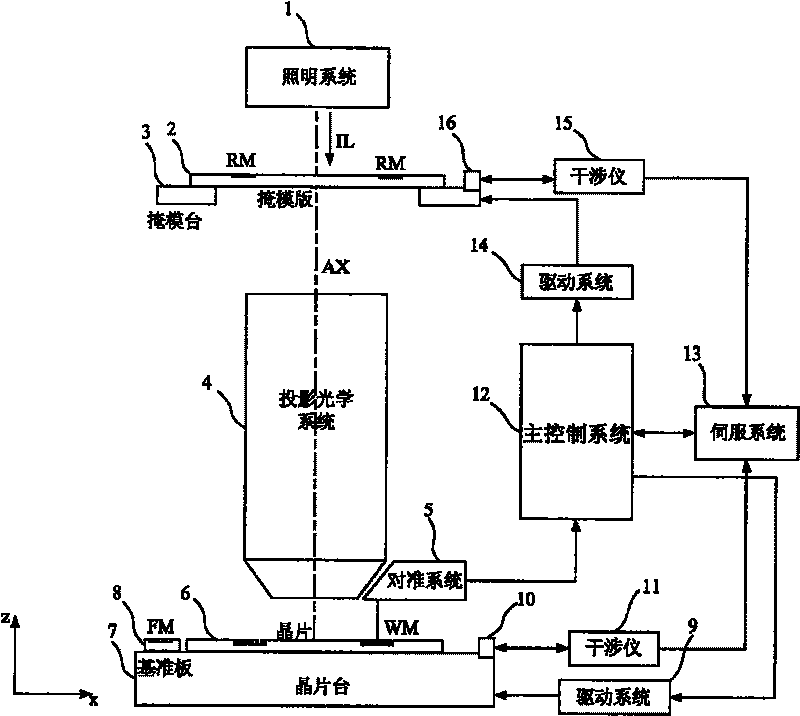

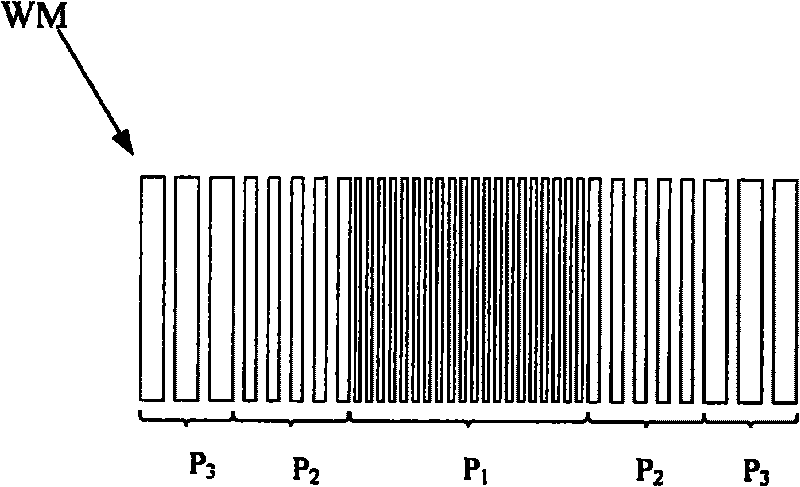

[0046] figure 1 It is a schematic structural diagram of the alignment system of the lithography apparatus of the present invention and the overall layout and working principle between the alignment system and the existing lithography apparatus. like figure 1 As shown, the composition of the lithography apparatus includes: an illumination system 1 for providing exposure beams, an alignment mark RM reticle 2 provided with a mask pattern and a periodic structure, and a mask table 3 for supporting the reticle 2 , a wafer 6 provided with an alignment mark WM of a periodic optical structure, a wafer stage 7 for supporting the wafer 6 , and a projection optical system 4 for projecting the mask pattern on the reticle 2 onto the wafer 6 . On the wafer stage 7, there is a reference plate 8 engraved with a reference mark FM. In addition, the lithography apparatus includes an off-axis alignment system 5 for mask and wafer alignment, mirrors 10, 16 and interferometers 11, 15 for measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com