Low-opacity release paper, release paper backing and methods

A technology of release paper and backing, applied in the direction of copying/marking method, paper making, paper coating, etc., which can solve the problem of expensive preparation of high-density paper products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The method of making the release paper and release paper backing of the present invention can be accomplished by forming a core sheet, applying the first and second coatings and hot soft calendering the overall product. These steps can be accomplished using conventional papermaking equipment. For example, the core can be formed by a continuous process using a Fourdrinier paper machine or with a twin wire forming section. The Fourdrinier paper machine includes a "wet end" where the pulp is mixed and then deposited on a screen, pressed and dried. Dye can be added at the wet end before the sheet forming section of the paper machine. This generally promotes even incorporation of the dye into the core.

[0056] In embodiments comprising a first coating and a second coating, these coatings may be applied separately or simultaneously. A variety of coaters can be used to apply the primary coat and / or the secondary coat, including: knife coaters, roll coaters, gravure coaters...

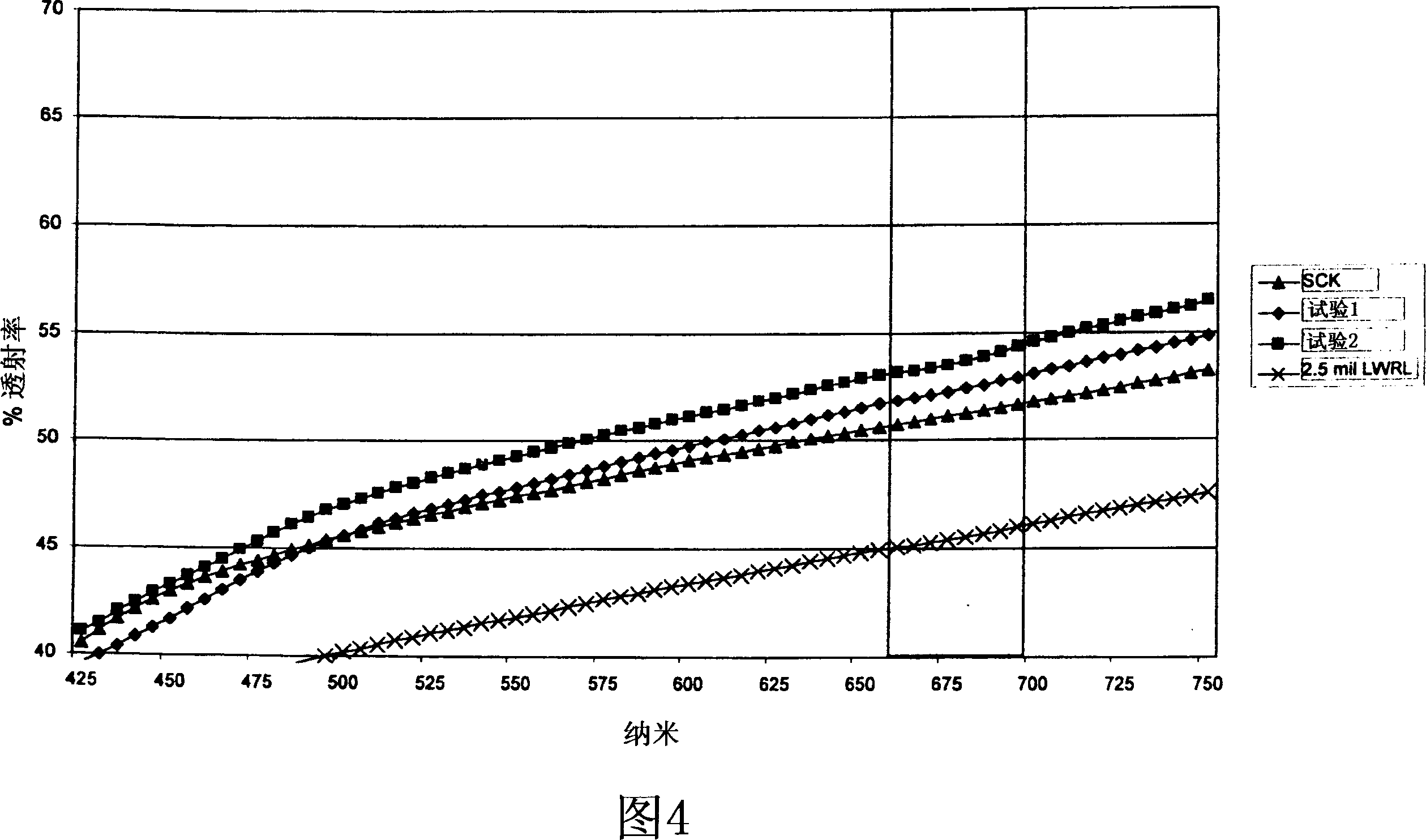

Embodiment 1

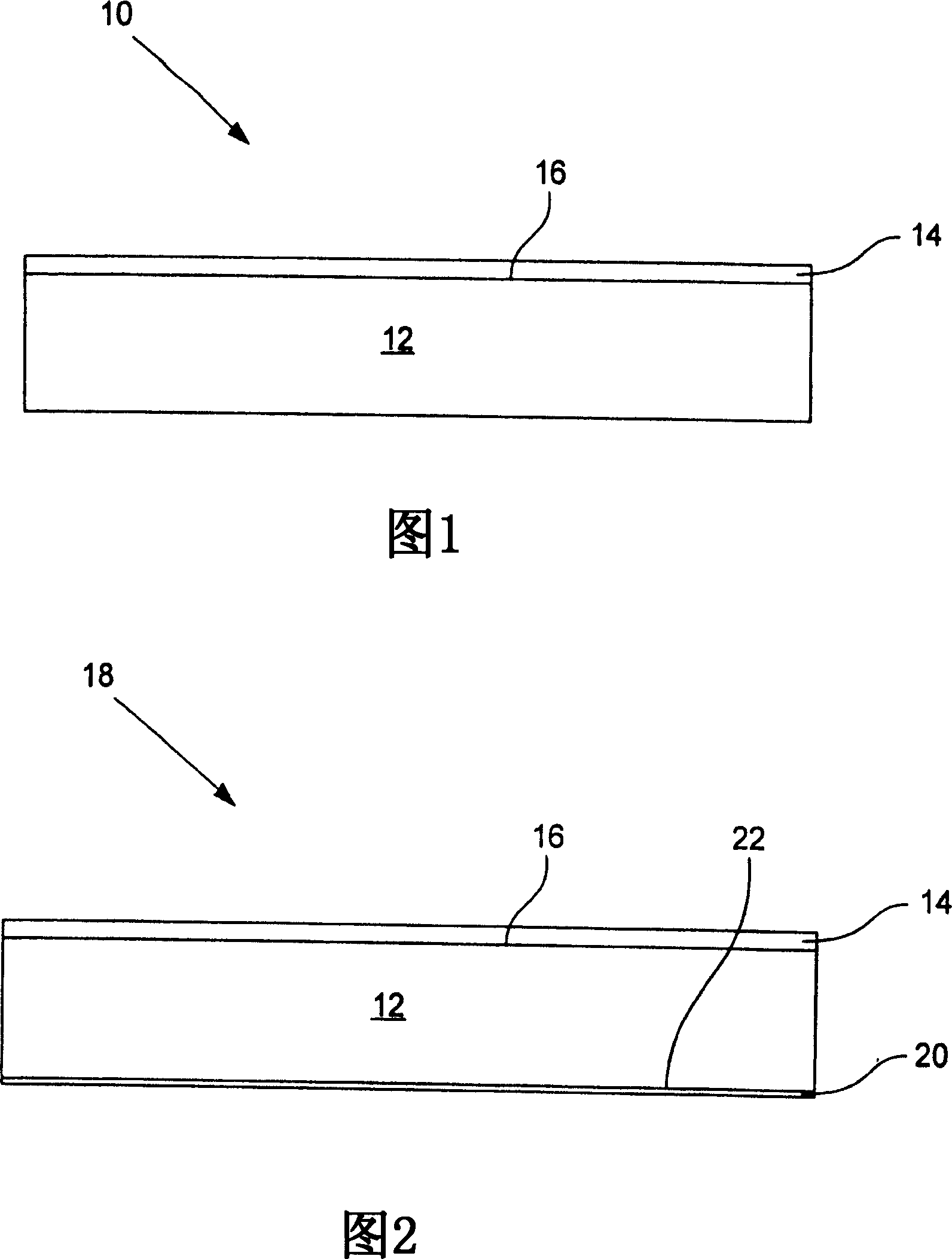

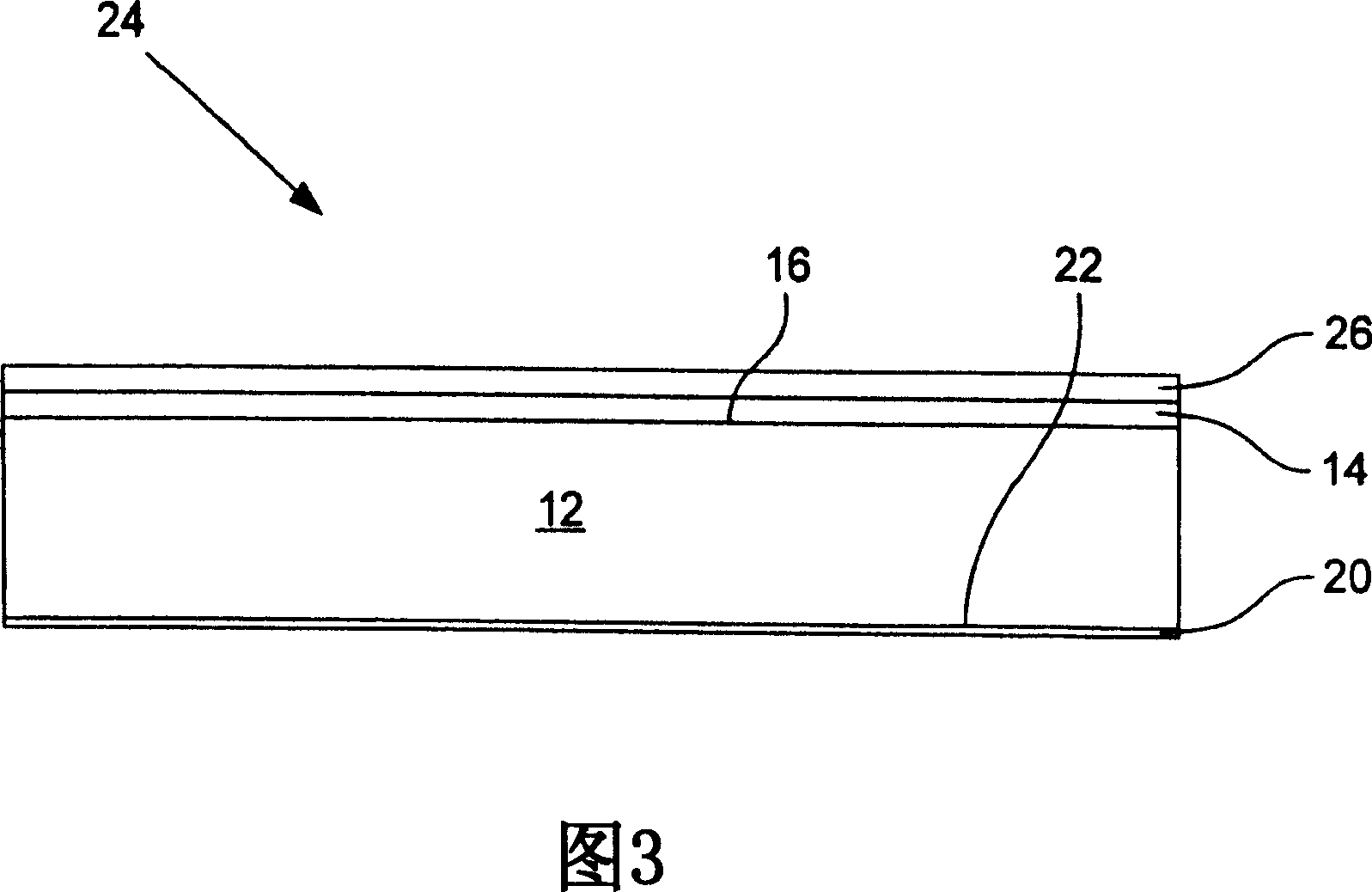

[0071] This example describes an exemplary embodiment of the release paper backing of the present invention. This embodiment includes a core, a first coating, and a second coating arranged in the configuration shown in FIG. 2 .

[0072] The coreboard consists of bleached chemical pulp from the kraft pulping process, containing both hardwood and softwood fiber types. Yellow dye was added to the core material at about 1.9 oz / ton. The yellow dye was CARTOSOL supplied by Clariant Corporation (Muttenz, Switzerland) Yellow 3GF.

[0073] The first coat comprises about 100 parts clay, about 5 parts starch, about 25 parts latex, and about 1 part crosslinker. This first coat is applied such that the clay, starch, latex and crosslinker are each applied in amounts of approximately 5.0 lbs / 3000 ft 2 (260lbs / ton), about 0.25lbs / 3000ft 2 (13lbs / ton), about 1.2lbs / 3000ft 2 (66lbs / ton), about 0.05lbs / 3000ft 2 (2.7lbs / ton). The total application amount of the first coat is about 6.5lb...

Embodiment 2

[0080] This example describes the method used to prepare the release paper backing described in Example 1. Bleached chemical pulp and yellow dye are mixed at the wet end of a Fourdrinier paper machine. After pressing and drying, the first and second coats were applied, respectively, using a knife coater and a roll coater in a simultaneous double-side coating application system. The coated product was subsequently calendered in-line with two nips for hot soft calendering. The calender rolls are heated to about 200 F to about 250 F and loaded to 500 pli to about 1000 pli.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com