Method and system for operating physical gas-phase deposition

A physical vapor deposition and device technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems that are difficult to realize, and achieve the effect of high device output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] According to the present invention, there are provided techniques related to integrated circuits and integrated circuit processing methods for manufacturing semiconductor devices. More specifically, the present invention provides a method and system for operating a physical vapor deposition process using active feedback control for fabricating semiconductor integrated circuit devices. It should be recognized, however, that the invention has broader applicability. For example, the invention can be applied to various other applications such as displays, MEMS.

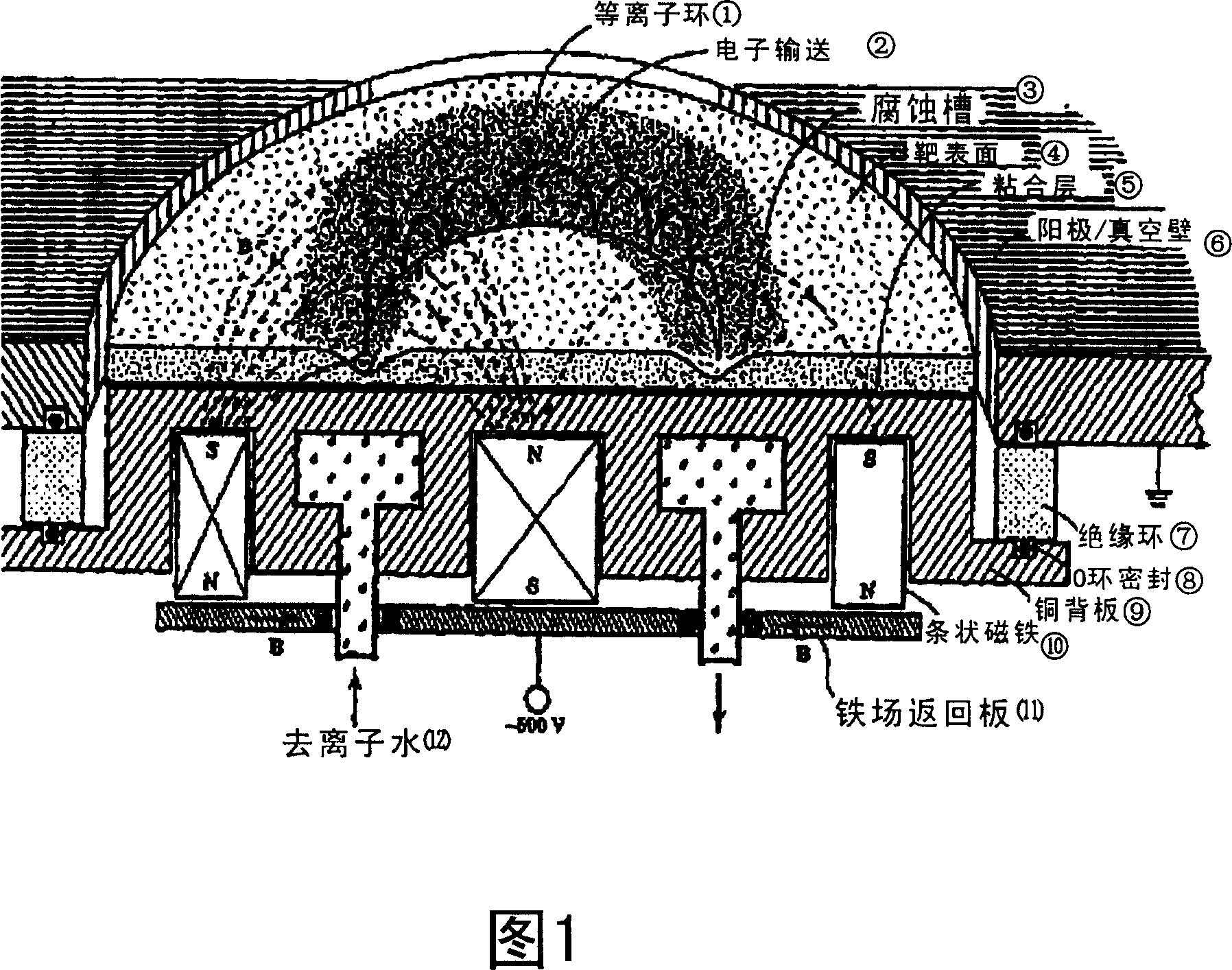

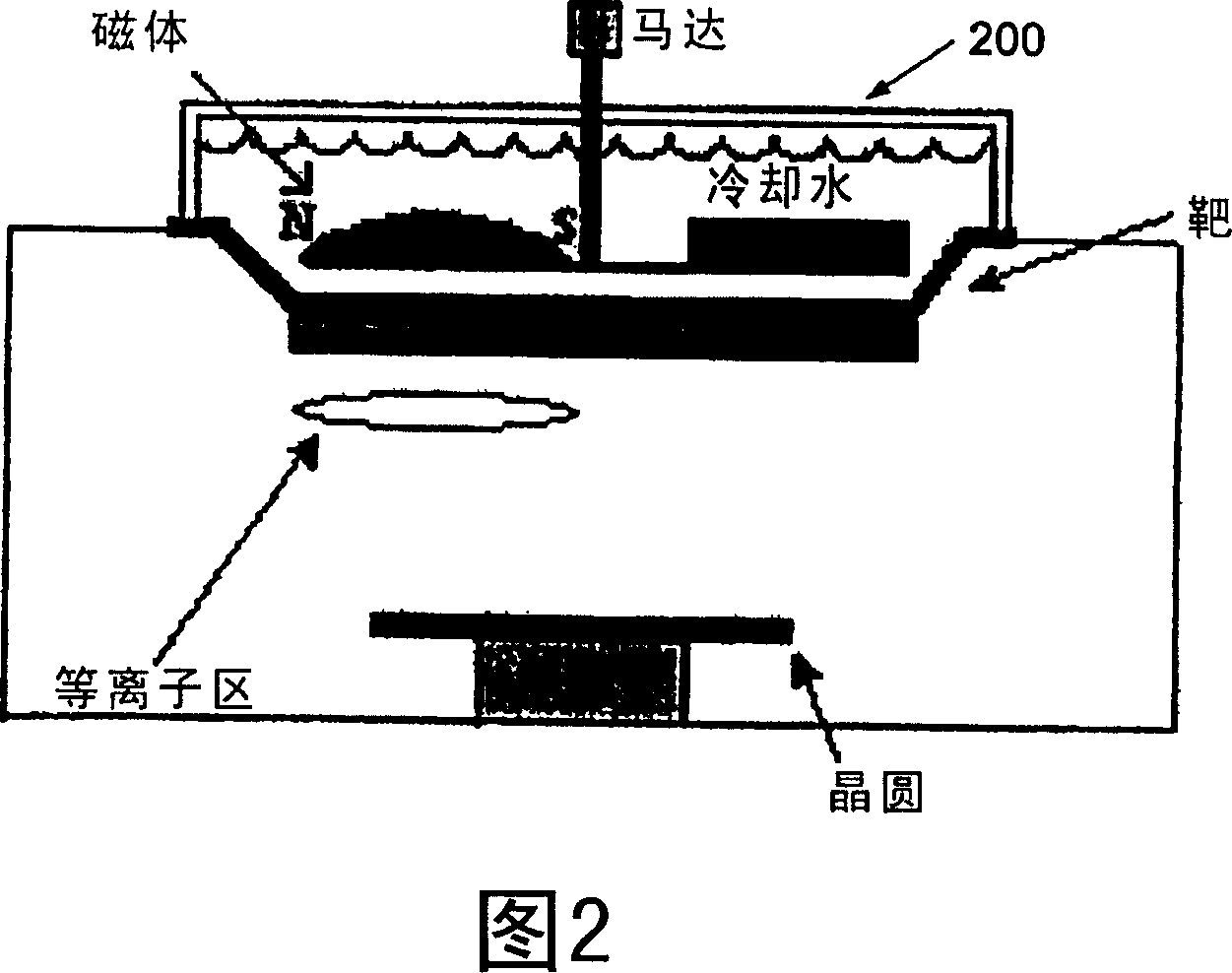

[0020] FIG. 1 is a simplified cross-sectional illustration of a conventional PVD system 100 . As shown, a PVD system (which is widely used to deposit metal layers and related materials in the process of fabricating semiconductor integrated circuits) includes a flat metal target to be sputtered and a wafer to be coated opposite the metal target. Working gas (usually argon) fills the reaction chamber at low pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com