White-light luminescent component and its production

A white light-emitting and component manufacturing technology, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of difficulty in obtaining dispersants, foaming and cracks, and rising costs, and achieve the effect of improving luminous efficiency and color coordinates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

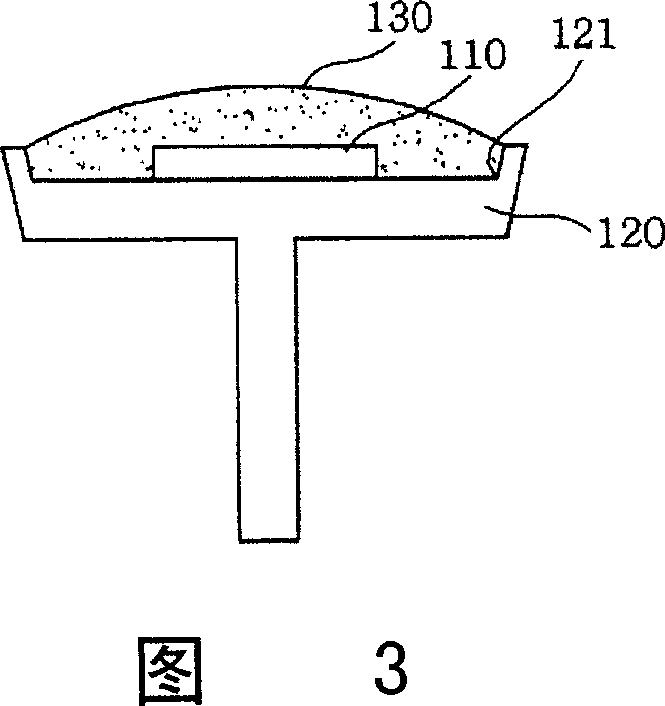

[0061] Embodiments of the white light-emitting element and its manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings.

[0062] FIG. 3 is a schematic conceptual diagram of a state in which a polymer resin in which organic phosphors are melted and inorganic phosphors are dispersed is coated on the light emitting diode 110 according to the present invention. Wrap and bond the LEDs on the cup-shaped reflector 121 of the lead frame 120, and coat the polymer resin 130 in which organic phosphors are melted and inorganic phosphors are dispersed.

[0063] Here, the organic and inorganic phosphors function to absorb light emitted from the light emitting diode 110 to change the wavelength.

[0064] That is, the light emitted from the light emitting diode 110 passes through the organic and inorganic phosphors contained in the polymer resin 130 to generate white light and is emitted to the outside.

[0065] For example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com