Column type membrane assembly and its producing method

A column membrane and component technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as uneven distribution of fiber filaments, reduced overall strength, and reduced service life of membrane components, so as to avoid fiber The effect of dense silk, reducing pouring height and increasing pouring height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] First weigh 70 kilograms of epoxy resin and 30 kilograms of curing agent, and mix them fully for later use.

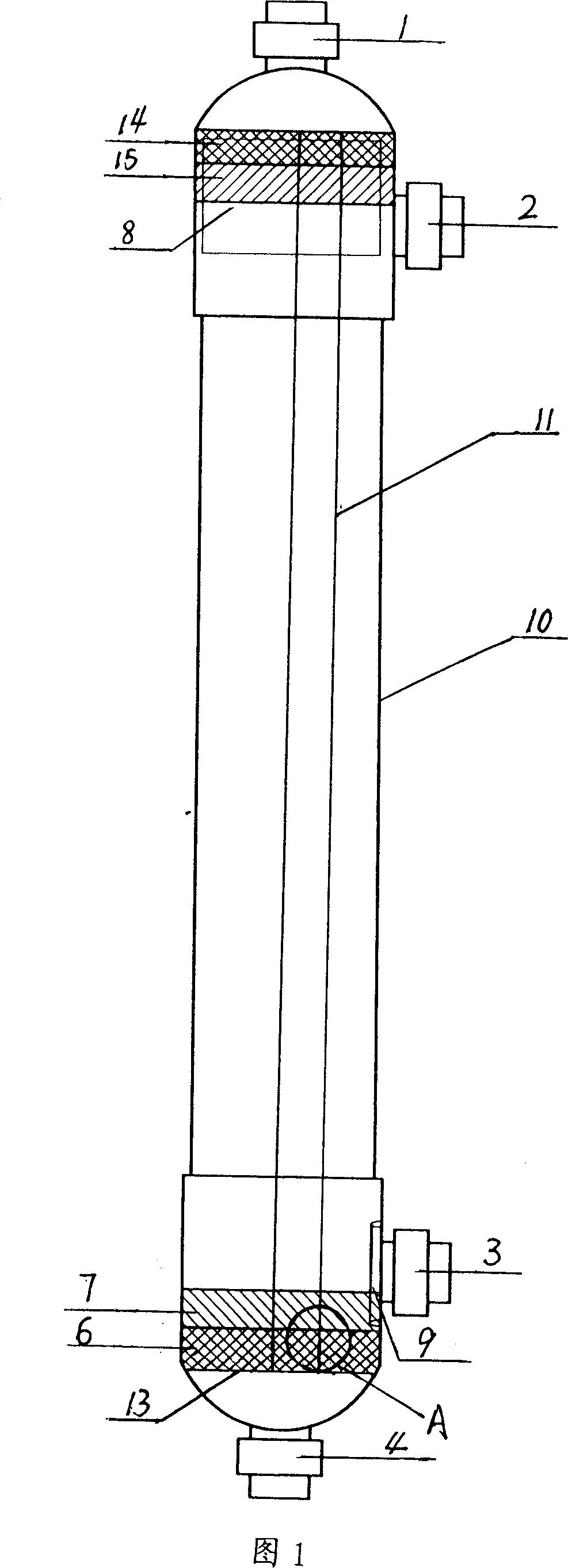

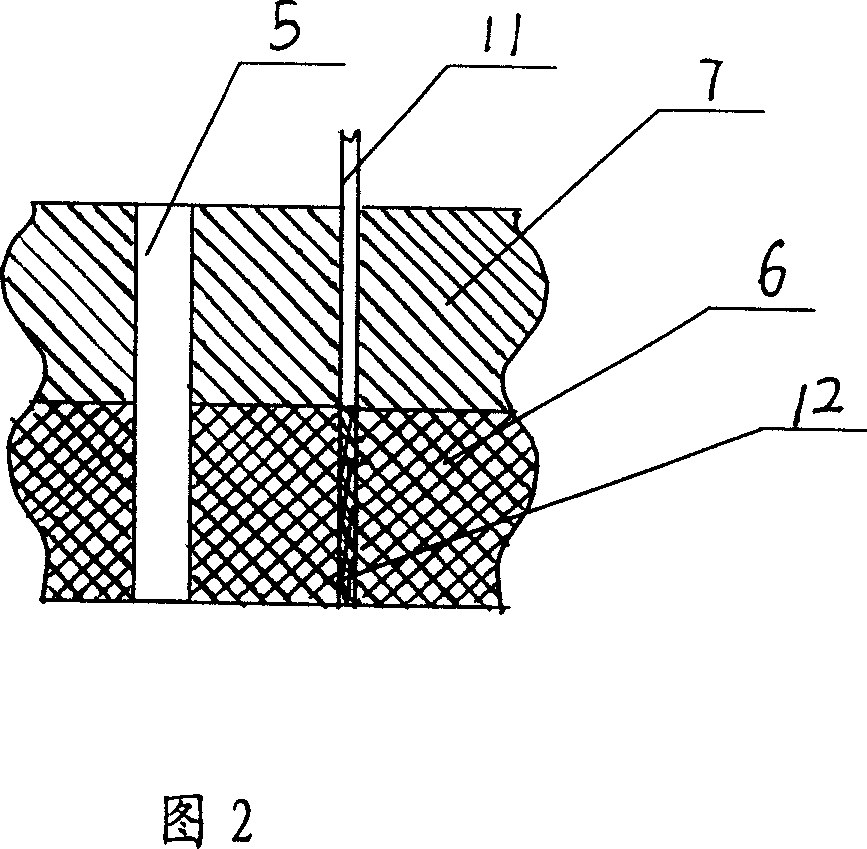

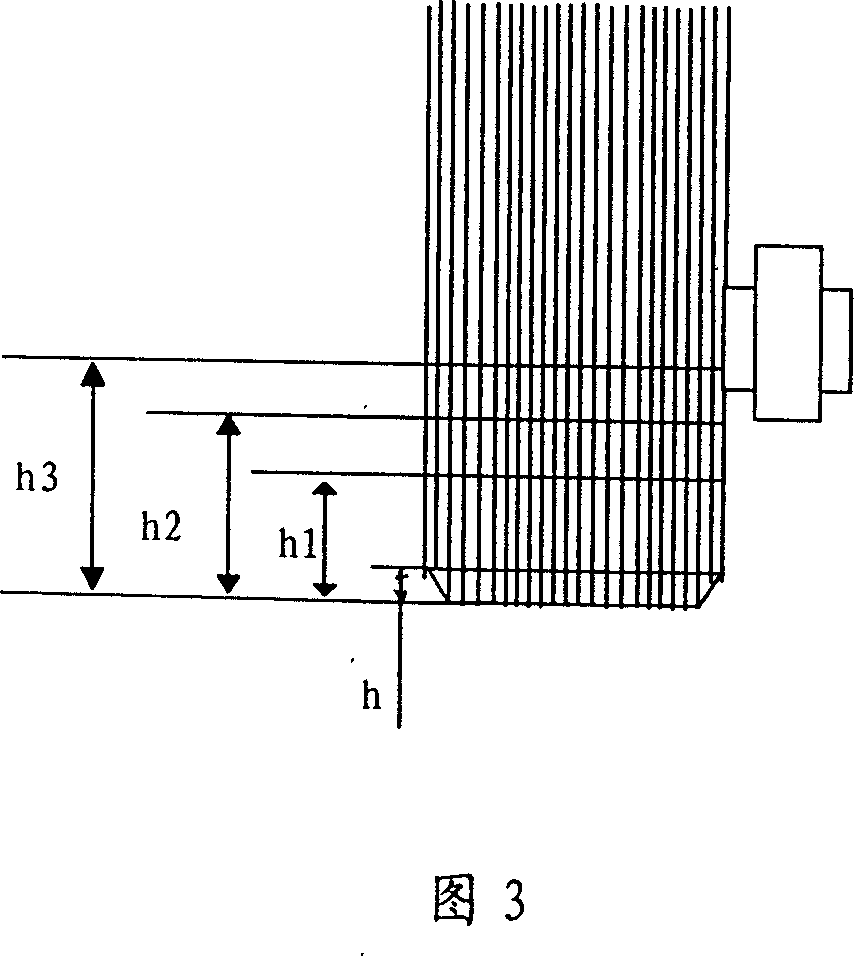

[0048]Glue the baffles and retaining rings on the spare port and the concentrate outlet. Fix one end of the fiber filament on the special support according to the specified amount of filament, and install the membrane shell. After that, cut the fiber at the outlet end to the specified length. Install the pouring plate at the water outlet and 15 diversion holes and socket columns. The depth h of the pouring plate groove is 2mm. Put the fibers exposed from the membrane shell into the pouring plate to ensure that the gap between the fiber and the bottom of the pouring plate is 2mm, The above-mentioned mixture of epoxy resin and curing agent is poured into the pouring pan at the end, and the pouring height h1 is 35 mm. After the surface has a certain strength, a resin fixed layer at the water outlet is formed. Polyurethane is poured into the pouring tray again, an...

Embodiment 2

[0050] The method is the same as in Example 1, wherein 80 kilograms of epoxy resin, 20 kilograms of curing agent, the gap between the fiber at the water outlet end and the bottom of the pouring pan is 6 mm, the gap between the fiber at the water inlet end and the bottom of the pouring pan is 6 mm, and the groove depth of the pouring pan is h is 10mm, the pouring height h1 of the resin fixed layer at the water inlet end and the resin fixed layer at the water outlet end is 23mm, and the pouring height h3 of the flexible protective layer at the water inlet end and the water outlet end is 60mm. The number of the diversion hole jack posts is 20. The flexible resin is silicone rubber.

Embodiment 3

[0052] Method is identical with embodiment 1, wherein 75 kilograms of epoxy resins, 25 kilograms of curing agent.

[0053] The gap between the fiber at the water outlet and the bottom of the pouring tray is 10mm, the gap between the fiber at the water inlet and the bottom of the pouring tray is 10mm, the groove depth h of the pouring tray is 20mm, and the pouring height of the resin fixed layer at the water inlet and the resin fixed layer at the water outlet h1 is 30mm, the pouring height of the flexible protective layer at the water inlet and water outlet to h3 is 65mm, and the number of diversion holes is 25. Flexible resins are elastomers.

[0054] The membrane module of the present invention has ultra-low operating capacity, higher water flux, wider water quality application range, can work under harsh water quality conditions, and has stable water production and excellent water quality, and is more suitable for large-scale reverse osmosis water control System preprocessi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com