Process for continuously preparing nitro-xylene isomer monomer

A technology of nitroxylene and nitro-m-xylene, applied in chemical instruments and methods, preparation of nitro compounds, preparation of organic compounds, etc.

Inactive Publication Date: 2007-04-11

GANSU YINGUANG CHEM IND GRP CO LTD

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Another major disadvantage is the need for post-treatment of spent acid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0069] The following examples cannot be interpreted as limiting the scope of protection of the invention.

[0070] raw material

[0071] raw material

[0072] raw material

[0073] raw material

[0074] raw material

[0075] raw material

[0076] raw material

[0077] raw material

[0078] raw material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention is continuous xylene isomer monomer nitrifying and rectifying process with sulfuric acid and nitric acid mixture to obtain nitro xylene isomer monomer. The optimized process has product yield over 97 %; consumption of xylene, nitric acid and sulfuric acid of 750kg / ton, 465kg / ton and 40kg / ton separately; and purity of the 2, 6-dimethyl nitrobenzene, 2, 4-dimethyl nitrobenzene, 3, 4-dimethyl nitrobenzene, 2, 3-dimethyl nitrobenzene and 2, 5-dimethyl nitrobenzene up to 99.5 %. When the process has the material changed from xylene to o-xylene or p-xylene and the technological conditions changed correspondingly, 3, 4-dimethyl nitrobenzene, 2, 3-dimethyl nitrobenzene and 2, 5-dimethyl nitrobenzene may be produced.

Description

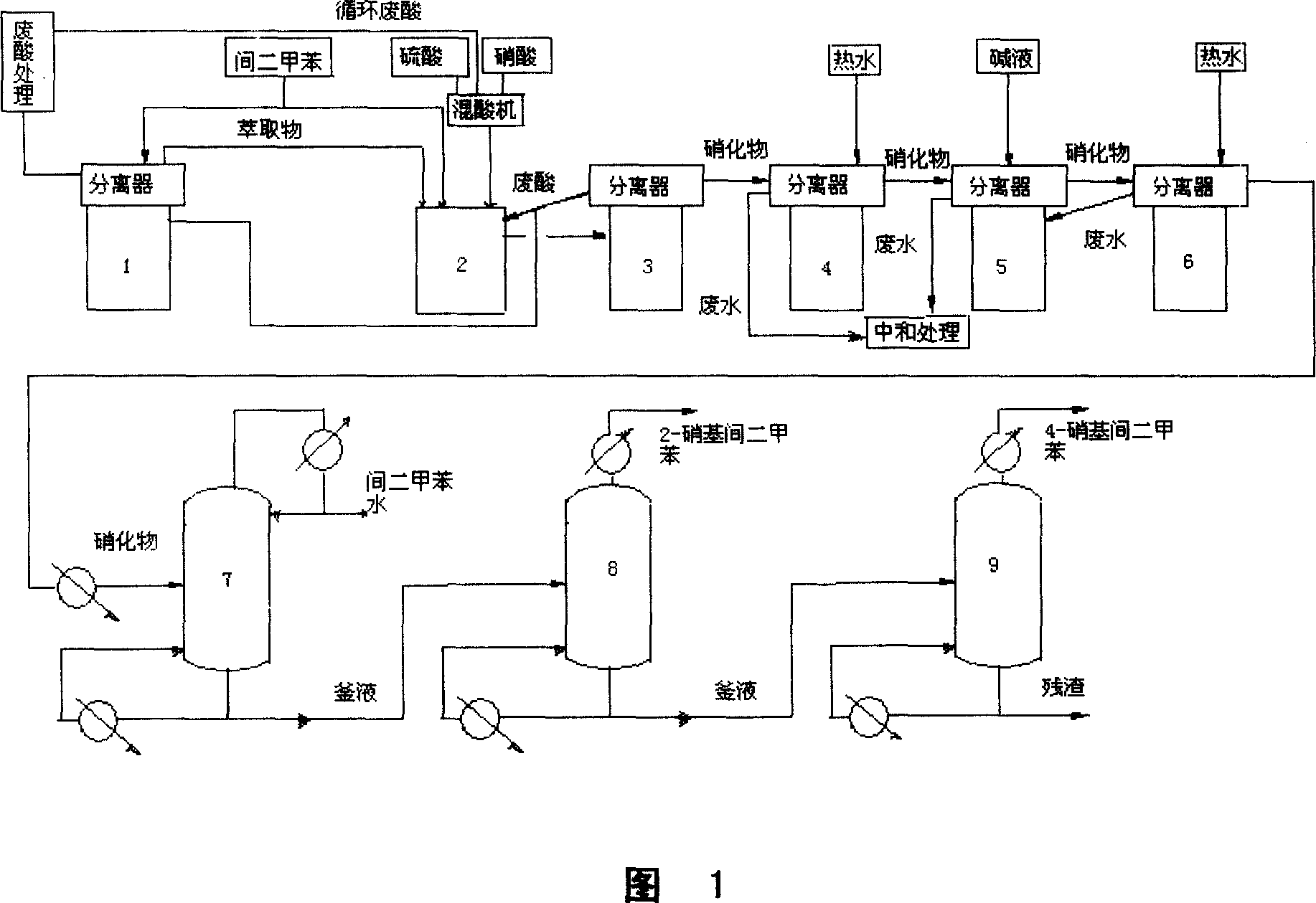

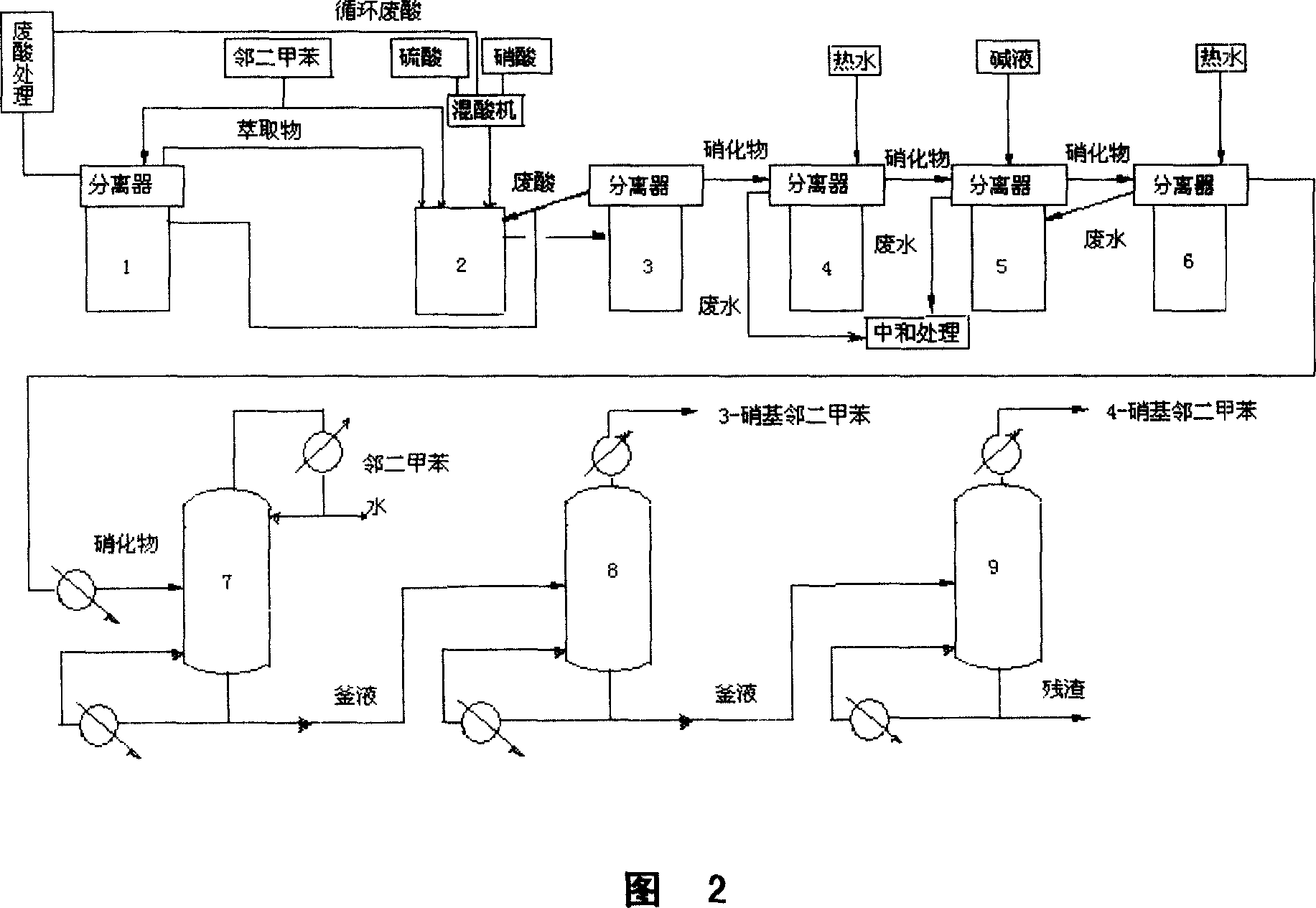

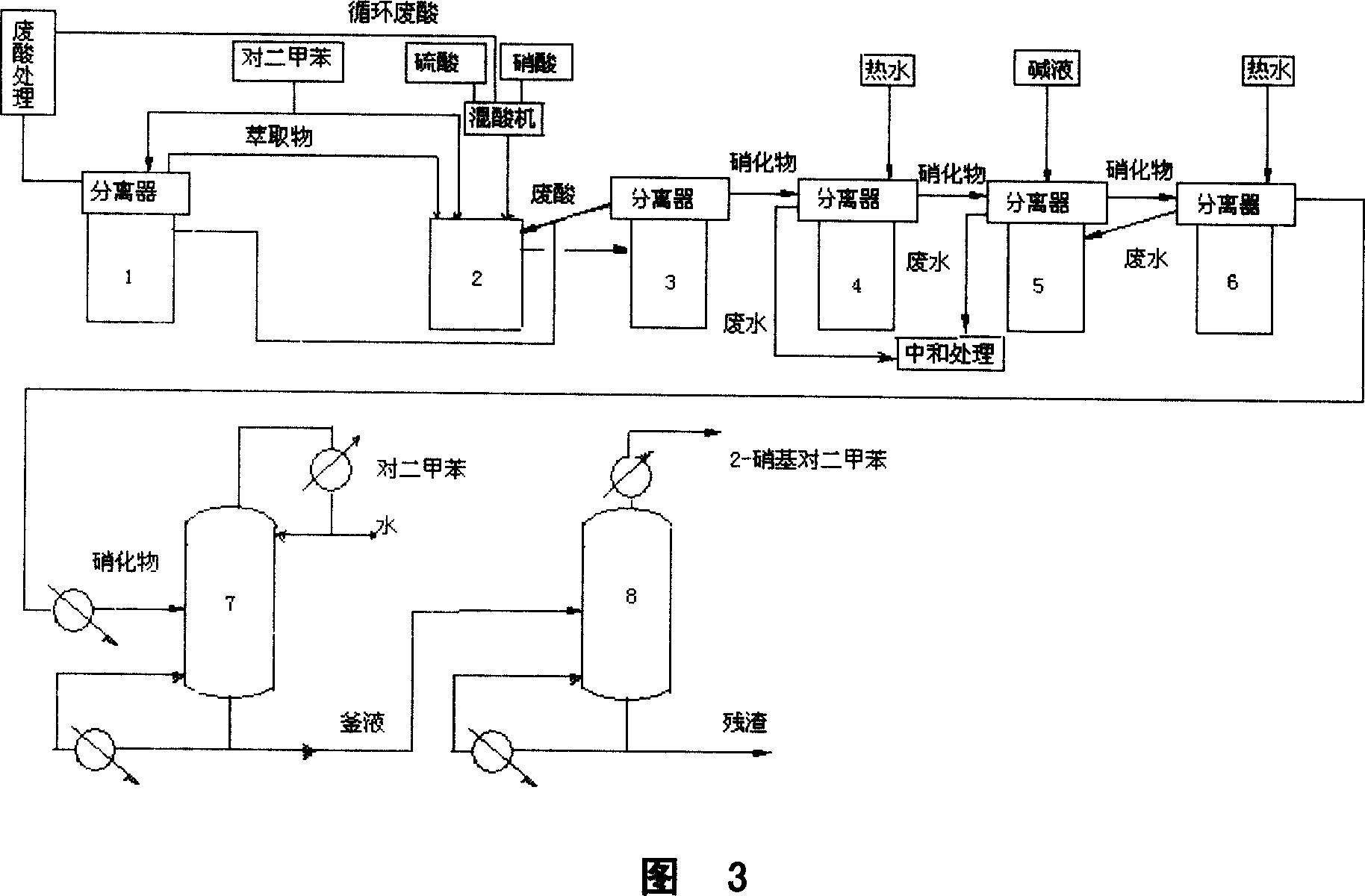

technical field [0001] The invention relates to a method for preparing nitroxylene isomer monomers by continuous nitration and continuous rectification with nitric acid, sulfur mixed acid and xylene isomer monomers, in particular to using nitric acid, sulfur mixed acid and m-xylene, ortho-xylene respectively. Nitration reaction of toluene and p-xylene and rectification to prepare 2-nitro-m-xylene, 4-nitro-m-xylene, 4-nitro-o-xylene, 3-nitro-o-xylene and 2-nitro-p-xylene Methods. technical background [0002] There are six isomers of nitroxylene, all of which have the molecular formula C 8 h 9 NO 2 , there are five kinds of industrial application value: 2-nitro-m-xylene is also known as 2,6-dimethylnitrobenzene or 2-nitro-1,3-dimethylbenzene; 4-nitro-m-xylene Xylene is also known as 2,4-dimethylnitrobenzene or 4-nitro-1,3-dimethylbenzene; 4-nitro-o-xylene is also known as 3,4-dimethylnitrobenzene Or 1,2-dimethyl-4-nitrobenzene; 3-nitro-o-xylene is also known as 2,3-dimet...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C201/08C07C201/16C07C205/06

Inventor 李伯文张岚韬张鹏尹本立盛振焓

Owner GANSU YINGUANG CHEM IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com