Method and apparatus for preparing p-xylene from methanol

A technology of p-xylene and methanol, applied in the field of producing p-xylene, can solve the problems of low comprehensive utilization rate of by-products, poor selectivity of xylene, etc., and achieve good economic benefits, increase yield, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

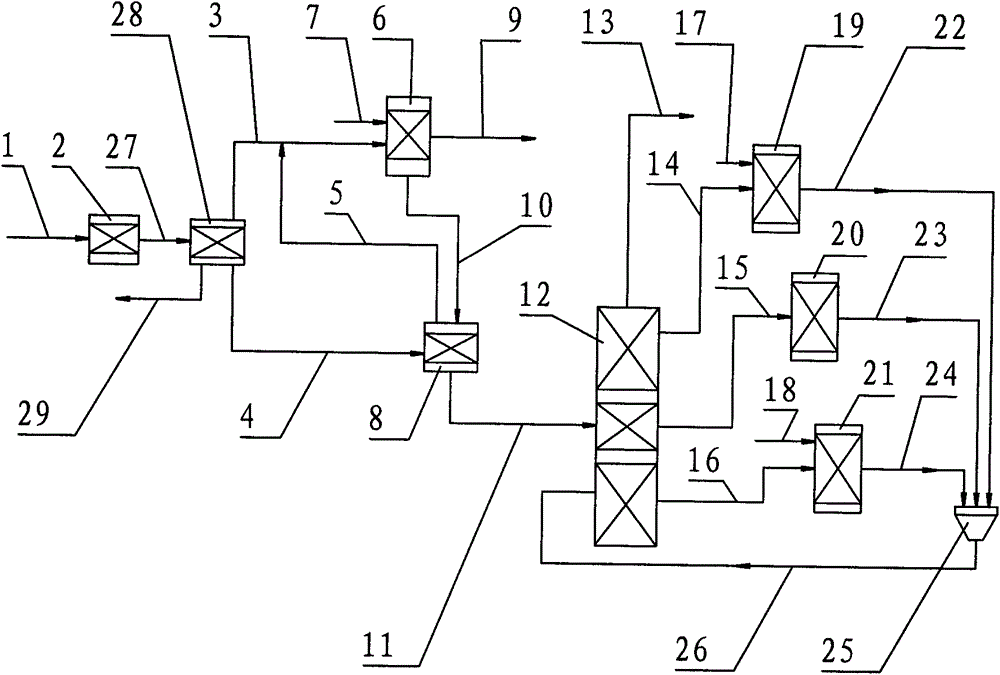

[0037] use figure 1 The device shown in the present specification is subjected to a pilot test according to steps A to G of the method for producing p-xylene from methanol according to the present invention described in the specific embodiment section. In step A, the reaction temperature of the methanol aromatization reaction is 380°C, and the feed weight space velocity is 1.0h -1 , the reaction pressure is 1.5MPa. The catalyst used for the methanol aromatization reaction is the ZnHZSM-5 catalyst described in "Research on the methanol aromatization reaction on ZnHZSM-5" in "Journal of Fuel Chemistry" No. 5, 2009, with a Zn loading of 2.0w%.

[0038] In step D, the reaction temperature for the aromatization reaction of low-carbon hydrocarbons is 360°C, and the weight space velocity of the feed is 0.5h -1 , the reaction pressure is 0.4MPa. The liquefied gas feed accounts for 15w% of the total feed to the low-carbon hydrocarbon aromatization reactor. The catalyst used for the...

Embodiment 2

[0043] According to Example 1, only the reaction temperature of the methanol aromatization reaction is 300°C, and the feed weight space velocity is 0.5h -1 , the reaction pressure is 0.5MPa. The reaction temperature of low-carbon hydrocarbon aromatization reaction is 300°C, and the feed weight space velocity is 0.3h -1 , the reaction pressure is 0.2MPa.

Embodiment 3

[0045] According to Example 1, only the reaction temperature of the methanol aromatization reaction is 350°C, and the feed weight space velocity is 1.0h -1 , the reaction pressure is 1.0MPa. The reaction temperature of low carbon hydrocarbon aromatization reaction is 380°C, and the feed weight space velocity is 0.6h -1 , the reaction pressure is 0.4MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com