Measurement stand for holding a measuring instrument

A technology of measuring instruments and measuring racks, which is applied in the direction of measuring instrument components, instruments, measuring devices, etc., to achieve the effect of improving precise start-up, realizing mechanical and highly precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

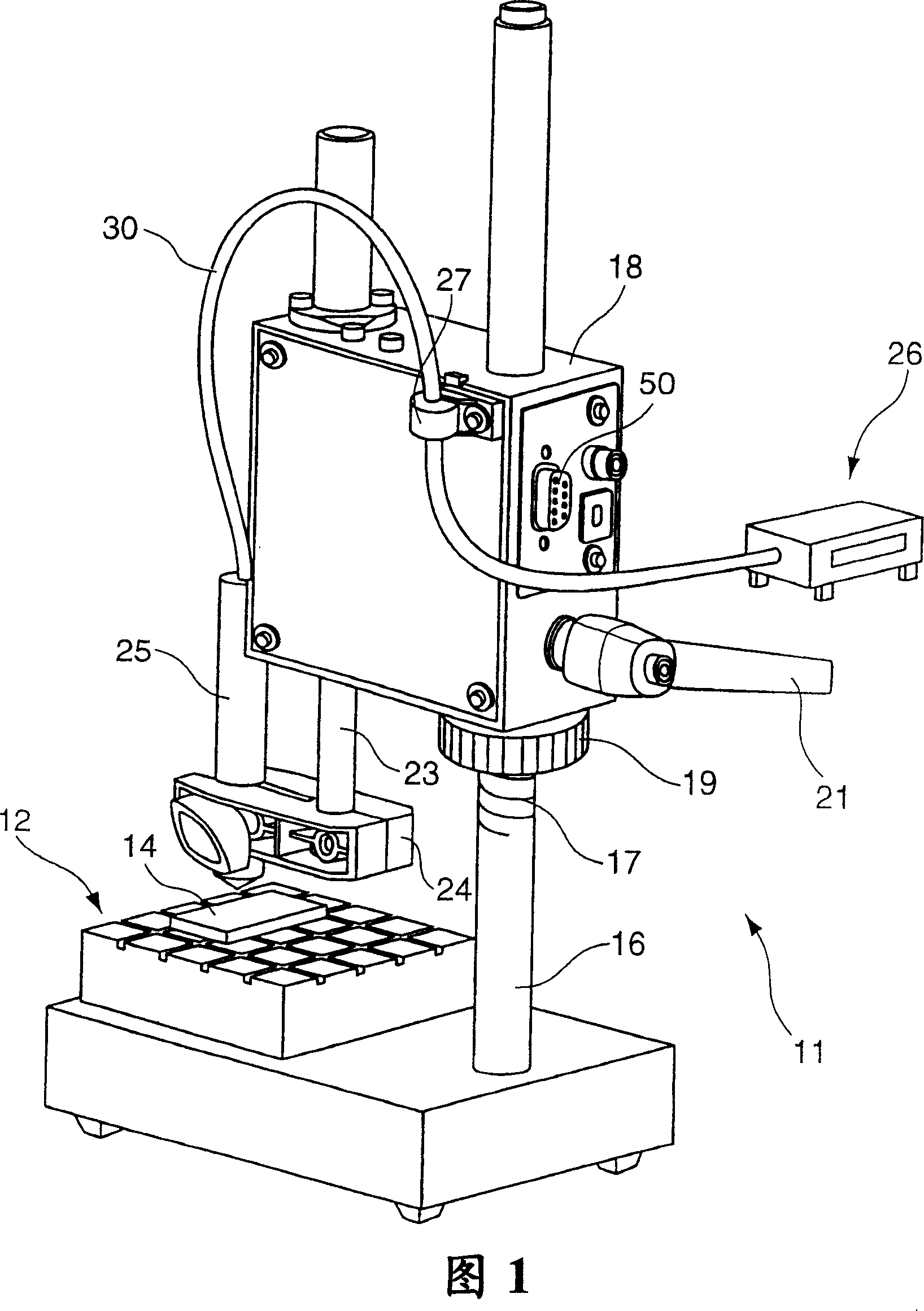

[0037] Figure 1 shows a measuring stand 11 according to the invention. Such a measuring stand 11 comprises a measuring table 12 on which individual measuring objects 14 can be positioned and placed. In the example shown, a magnetic slide is shown that accepts the object to be measured. The vertical column 16 holding the casing 18 is arranged on the bottom of the measuring frame 11 or on the measuring platform 12 , and the casing 18 can be adjusted vertically through the thread 17 . The height of the housing 18 can be precisely adjusted by adjusting the screw 19 and the clamping mechanism 21 .

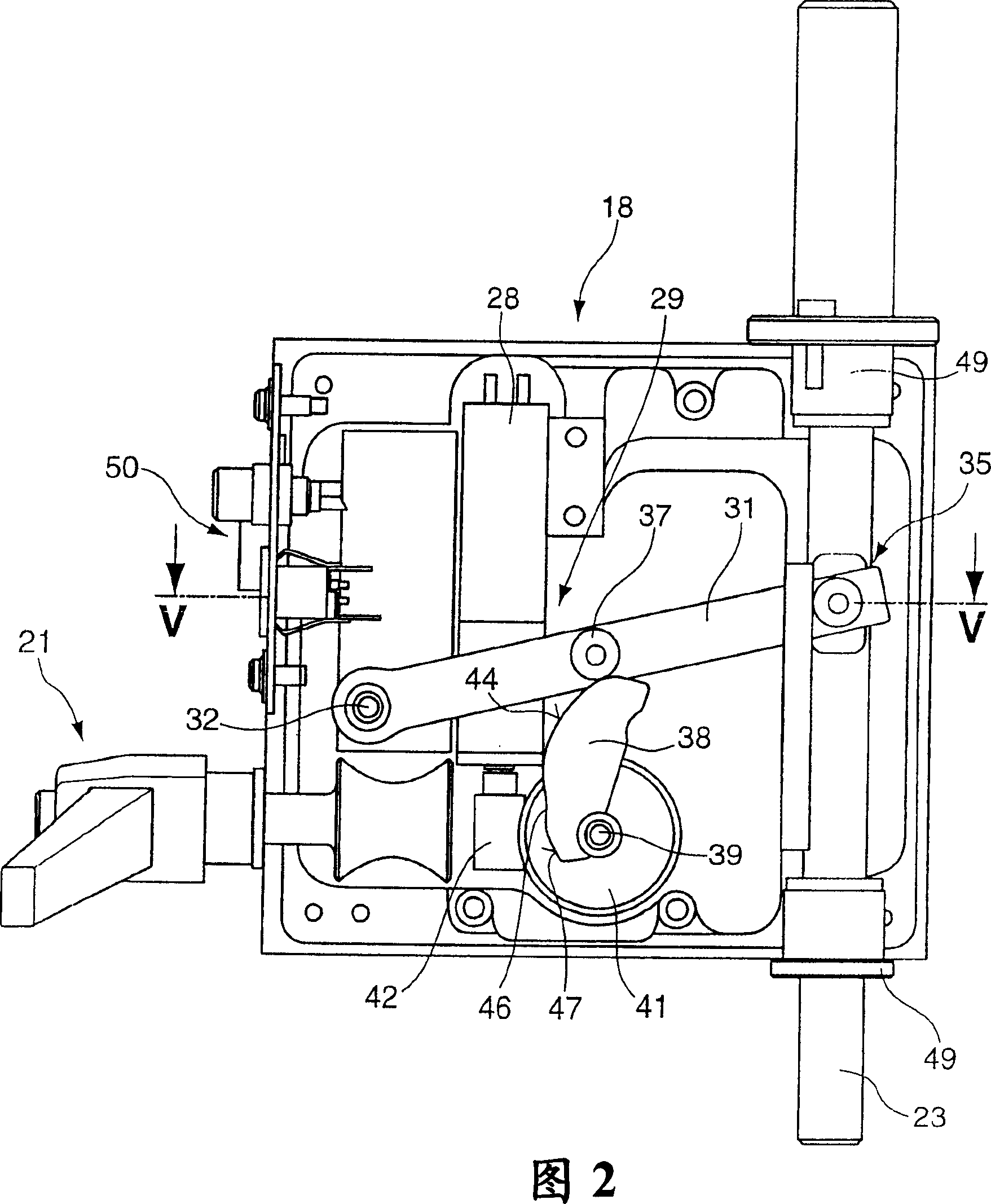

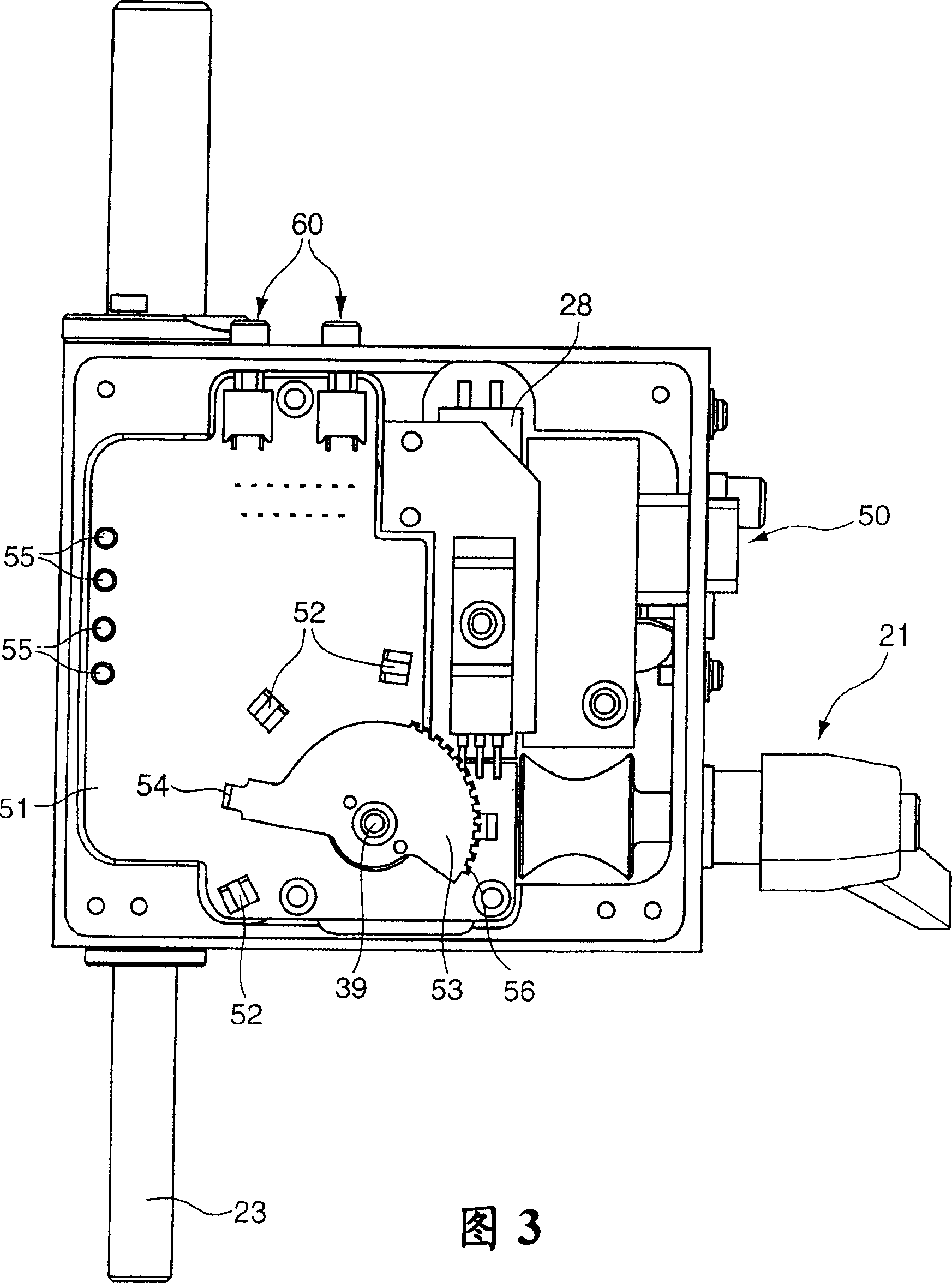

[0038] The housing 18 accommodates the cam follower 23 so that the cam follower 23 can move up and down. A holding device 24 for detachably fixing a measuring instrument 26 is provided at the lower end of the cam follower 23 . The measuring device 26 comprises a measuring probe 25 for measuring the thickness of the thin layer. Such a measuring probe 25 can be touched on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com