Power electronic power device module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

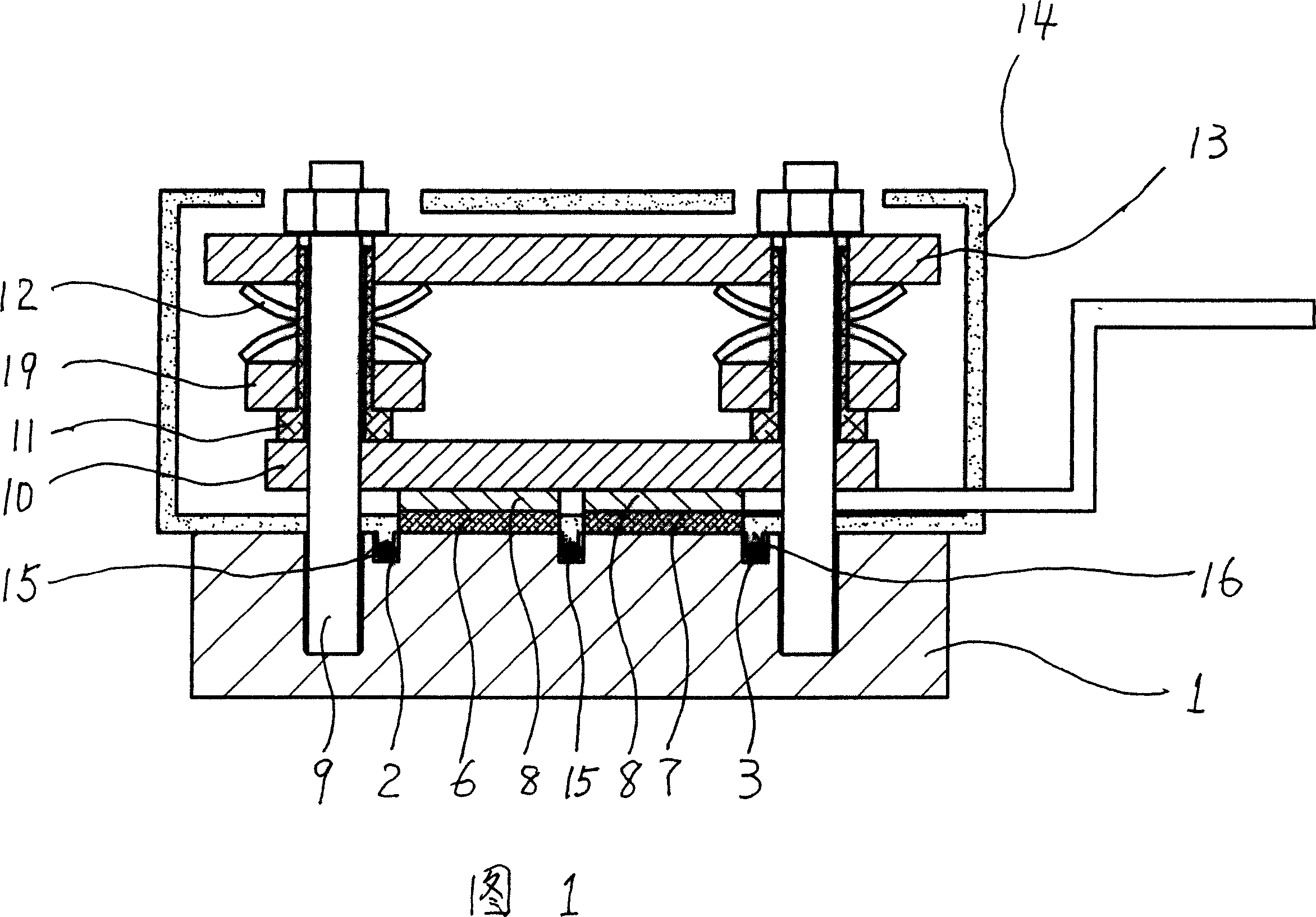

[0016] The structure and operating principle of a power electronic power device module provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

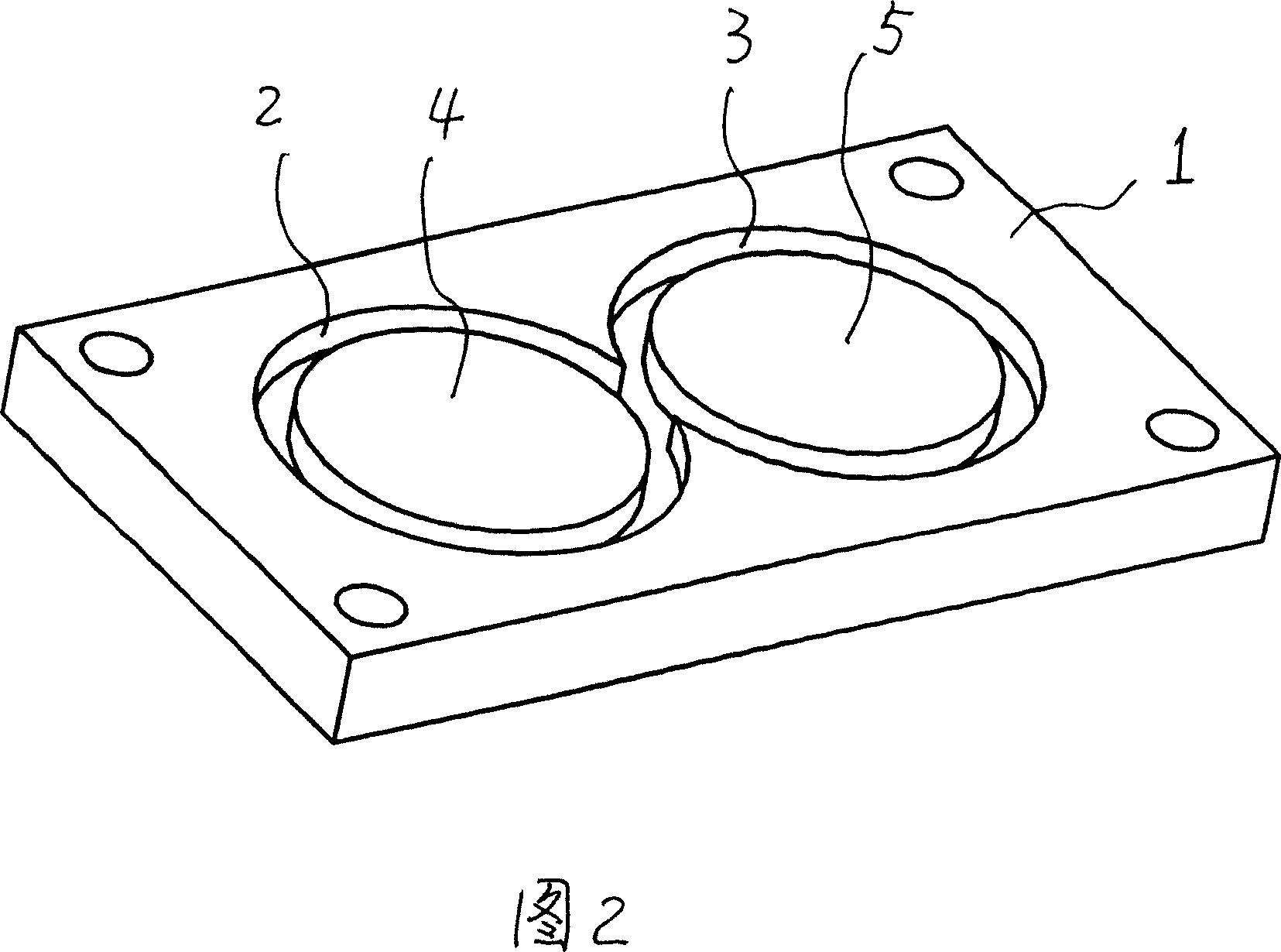

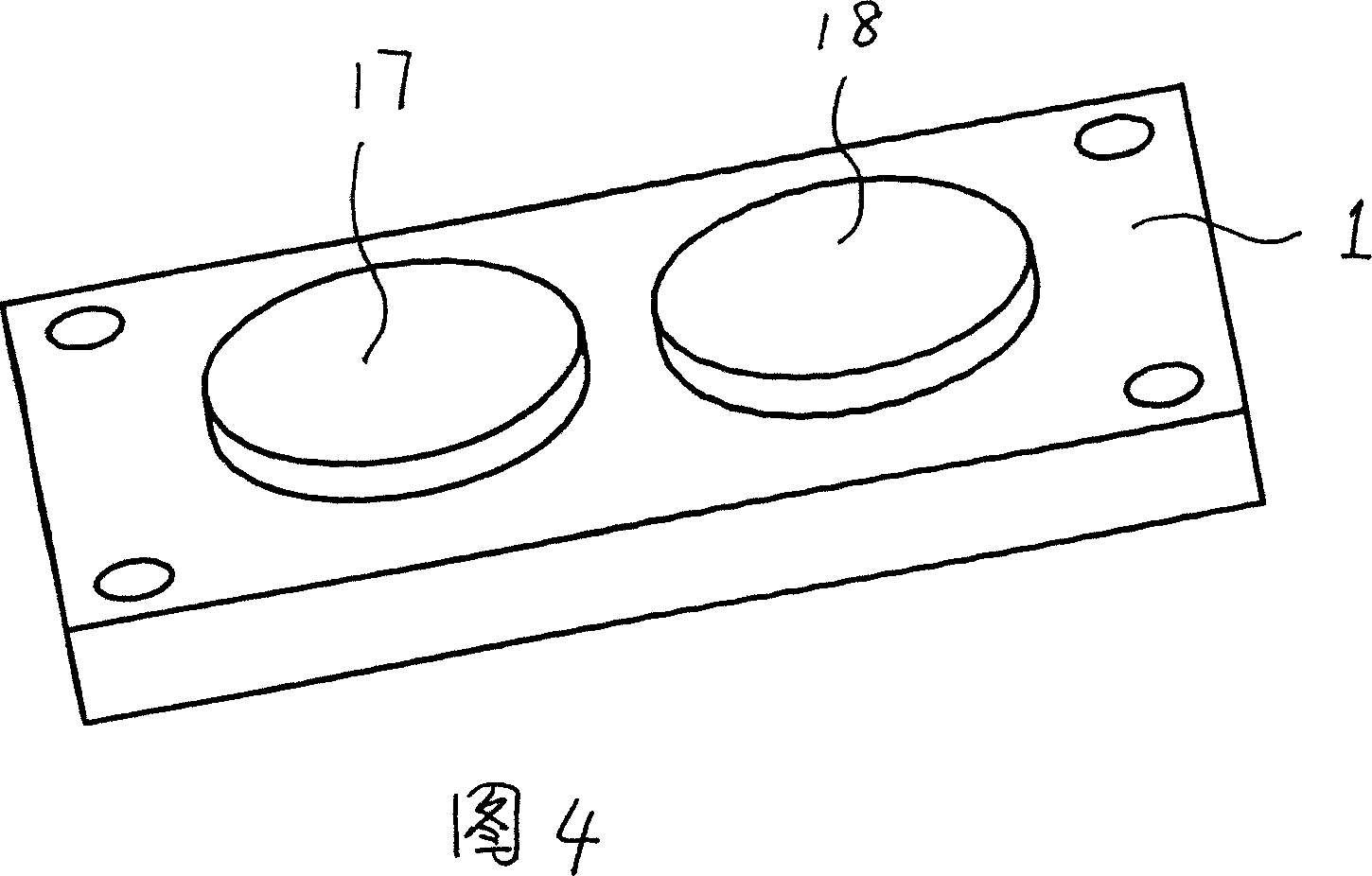

[0017] As shown in Figure 1, it is a schematic structural diagram of a power electronic power device module, including a base plate 1 of a heat dissipation component made of metal copper, aluminum or an alloy material, and as shown in Figure 2, there are two annular grooves on the base plate 2, 3, circular convex surfaces 4 and 5 are formed in the middle of the annular groove, and insulating plates 6 and 7 with heat dissipation function are respectively pasted on the two circular convex surfaces, and the pressing block 10 fixed by the screw rod 9, the casing 11. The electronic chip fixing part and the housing 14 composed of backing plate 19, disc spring 12 and pressing plate 13 fix the electronic chip 8 and insulating plate with rectification or other functions on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com