Analog device and method of material property testing

A material performance, simulation device technology, applied in the measurement device, aerodynamic test, test wear resistance and other directions, can solve the problems of friction and wear of material test pieces, and achieve the effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

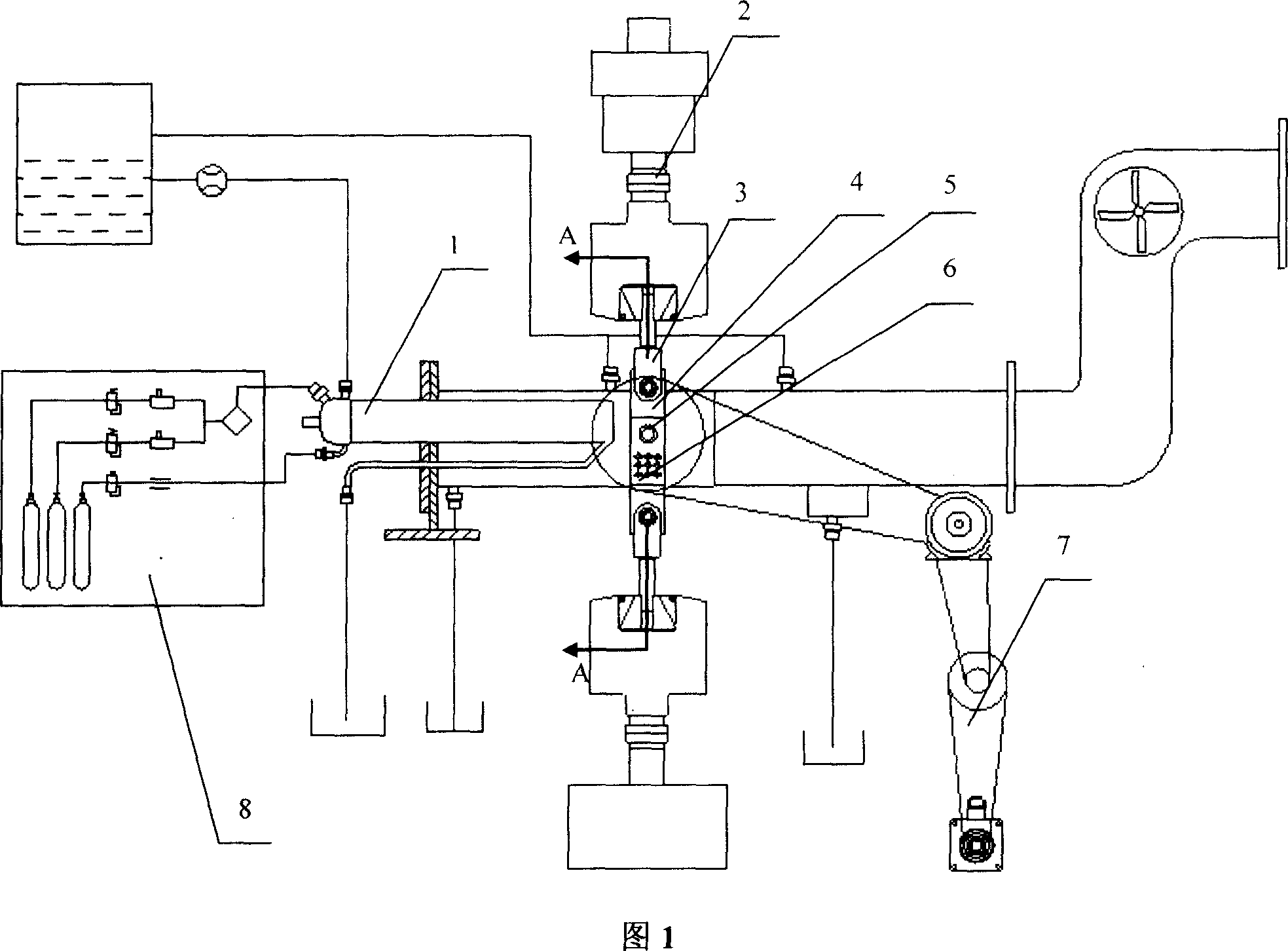

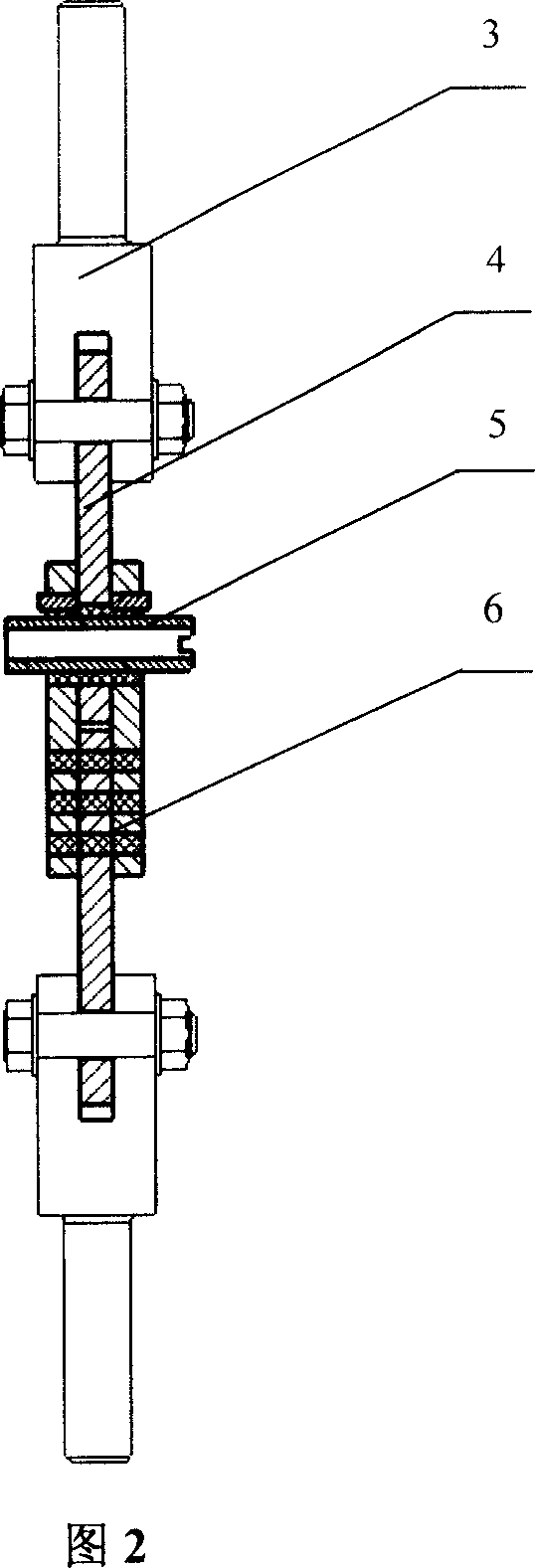

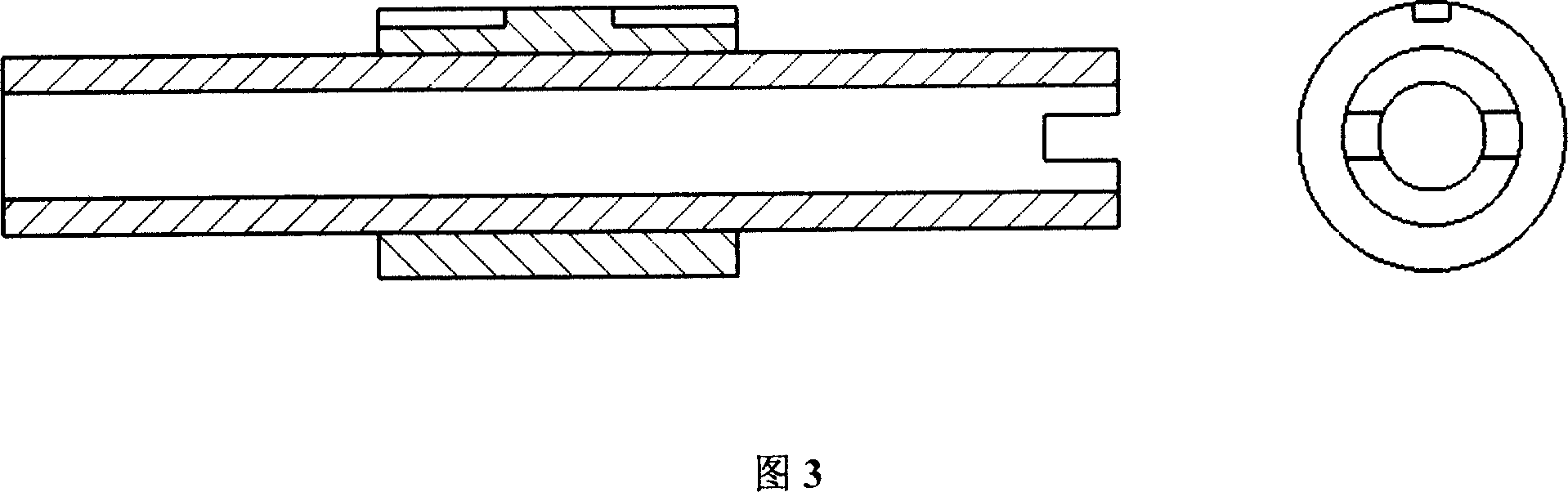

[0019] Referring to Figures 1 to 5, a small atmospheric pressure subsonic gas flow wind tunnel is used to generate a high-speed gas flow environment similar to the re-entry atmosphere environment, and the heating efficiency and maximum heating temperature can be improved by selecting the combustion agent and oxidant of the wind tunnel; Use the gas control system to adjust the gas composition to achieve an air environment similar to the re-entry process; design a servo drive and a special friction and wear test piece to solve the friction and wear problem of the material test piece in the simulated environment.

[0020] The small atmospheric pressure subsonic gas flow wind tunnel adopted by the present invention selects methane and oxygen-nitrogen mixed gas as fuel. Methane has a high combustion value and high heating efficiency, and it only takes 2 minutes to achieve a high temperature of 1800°C; the mixed gas of oxygen and nitrogen is used as the oxidant, and the ratio of oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com