Starch treatment process

A starch and resistant starch technology, applied in the field of starch, can solve problems such as poor water binding performance, difficult processing of resistant starch, poor component functionality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Characterization of Microfluidized Resistant Starch

[0065] viscosity

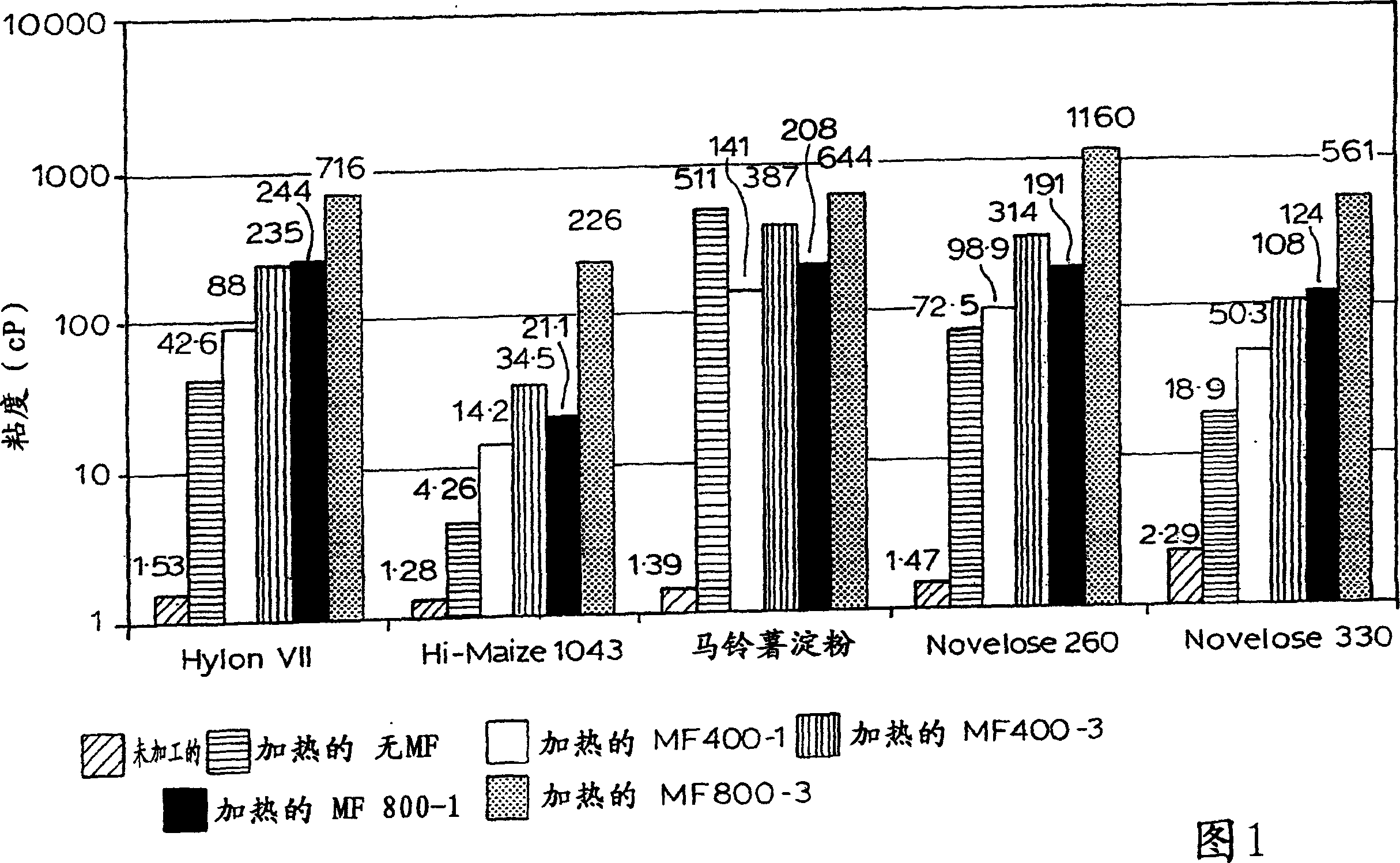

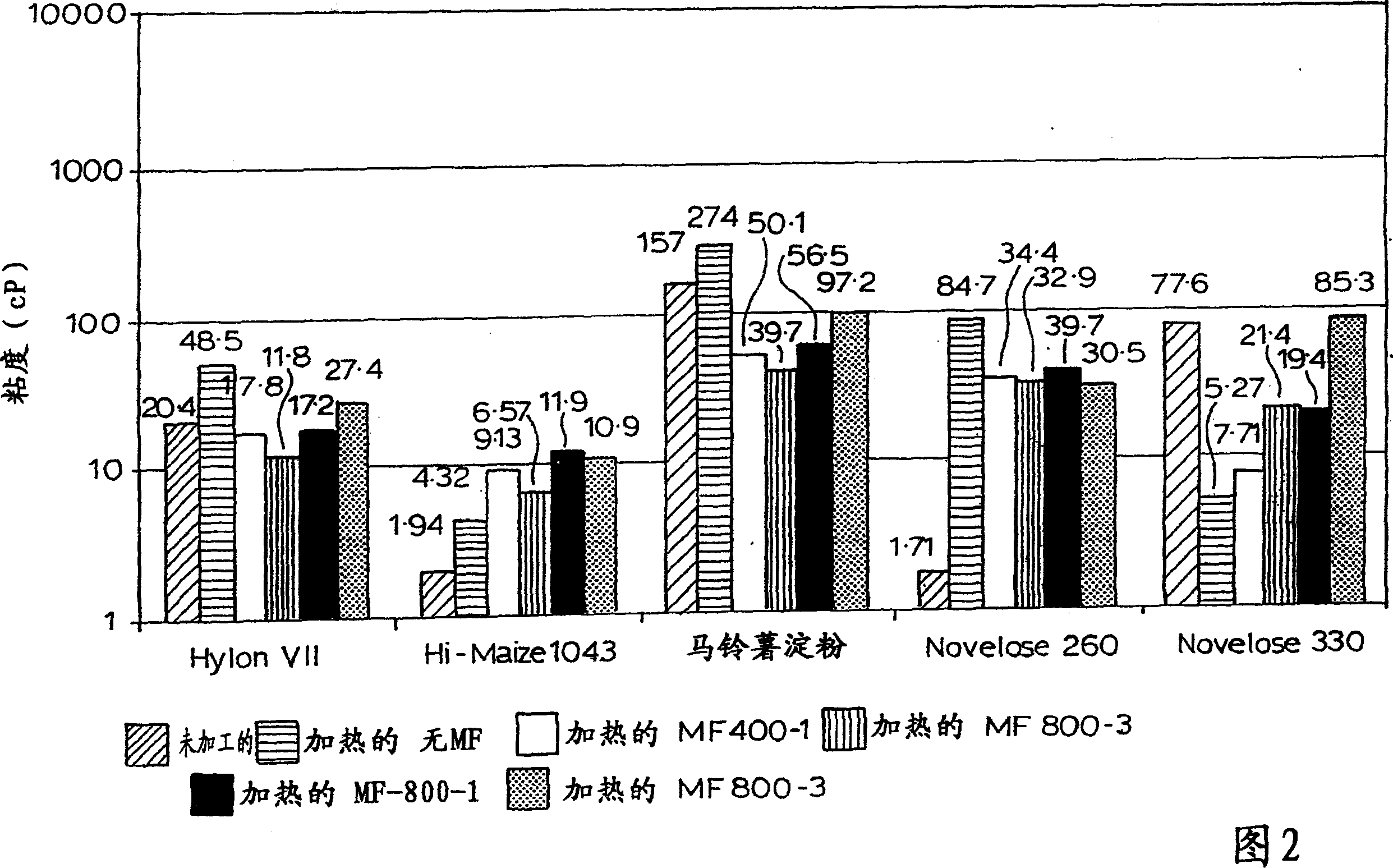

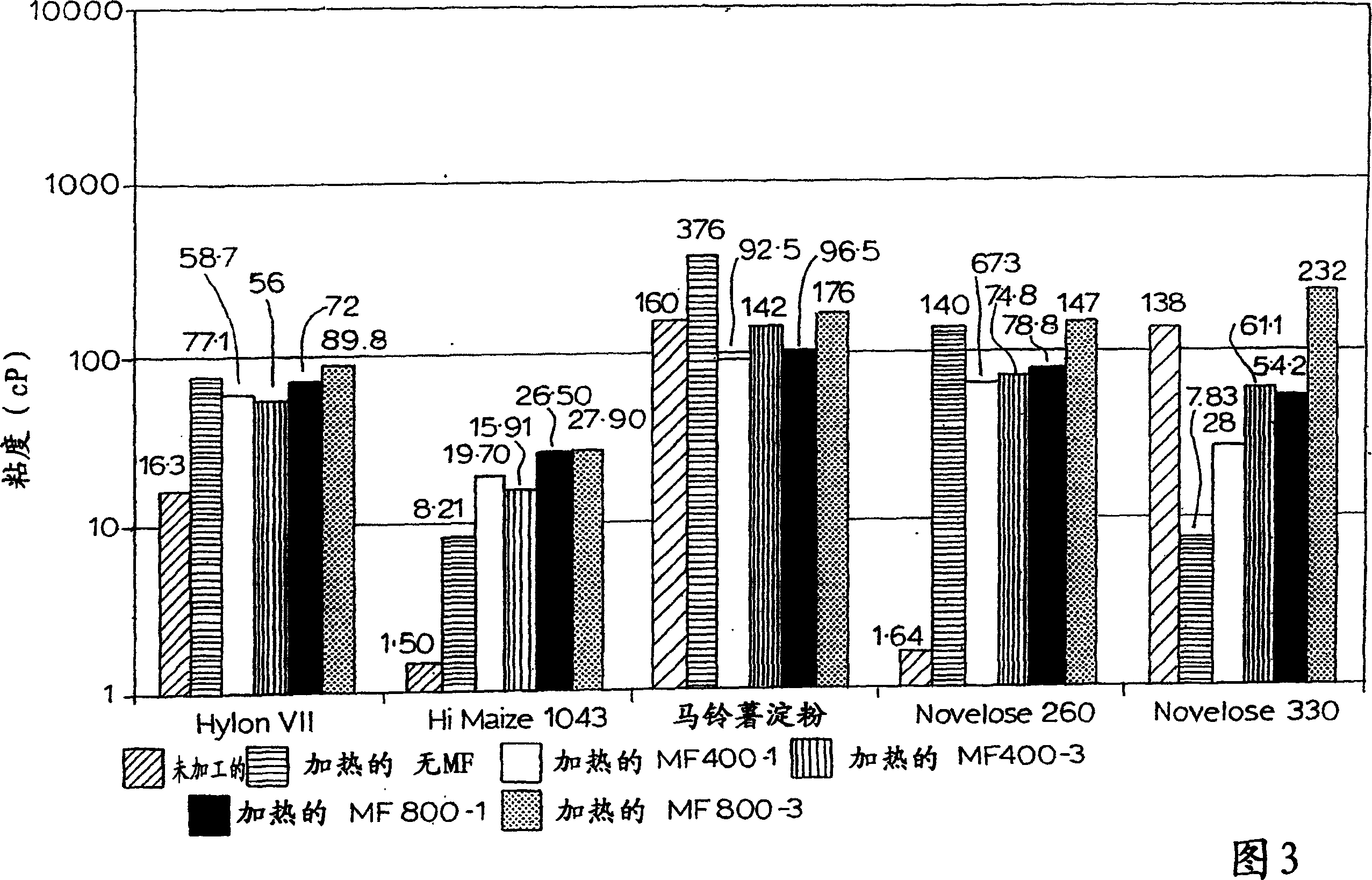

[0066] Figures 1 and 2 illustrate the effect of microfluidization on wet starch properties.

[0067] As expected, all raw resistant starches had a low viscosity (1.3-2.3 cP). As expected, heat treatment (121°C / 60 min) increased the viscosity of the starch suspension, because starch granules swelled and gelatinized with an accompanying increase in viscosity as the temperature increased. The combination of heat treatment and microfluidization significantly changed the viscosity of all processed resistant starch suspensions.

[0068] processed starch suspension

[0069] Figures 1 and 2 give the viscosities of these suspensions. In this case, the resistant starch was tested after it had been pretreated (ie heated at 121° C. / microfluidized) and was still in liquid state (10% ingredient weight / total suspension weight).

[0070] Viscosity at 50°C after treatment process

[0071] When heat...

Embodiment 2

[0094] Example 2: Characterization of resistant starch by high pressure processing or ultrasonic treatment

[0095] Table 4 lists selected properties of the processed starches.

[0096] feature

raw starch

(no processing)

ultrasonic treatment

of starch

pressure treatment

of starch

Resistant starch content

(% w / w dry basis)

Particle size (μm)

58

6.8 (mode value)

7.9 (average)

35

<0.75(mode frequency value)

1.3 (average)

35

<0.75(mode frequency value)

2.9 (average)

[0097] * Spray drying at inlet 185°C / outlet 80°C

[0098] After processing, about 60% of the initial resistance is retained. The particle size data indicated that there was a reduction in the treated starch particle size. The average molecular weight of starch also decreased (Figure 9).

Embodiment 3

[0099] Example 3: Characterization of Microfluidized Non-Resistant Cereal Starches

[0100] Treatment of non-resistant starches modified the properties of non-resistant starches (Table 5, Figure 10).

[0101] starch

deal with

resistant starch

content

(g / 100g dry basis)

particle size

(mode value)

(μm)

particle size

(average)

(μm)

No

Heating MF 800-1

No

Heating MF 800-1

No

Heating MF 800-1

0.9

6.3

0.4

0.5

0.3

9.6

11.0

<0.75

12.1

<0.75

3.8

<0.75

8.6

1.0

7.9

1.5

5.6

1.0

[0102] * Spray drying at inlet 185°C / outlet 80°C

[0103] The resistant starch content increased after treatment, which was also accompanied by a decrease in granule size. Figure 10 shows that this treatment caused the breaking of bonds within the wheat starch molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com