Affinity particle and affinity separation method

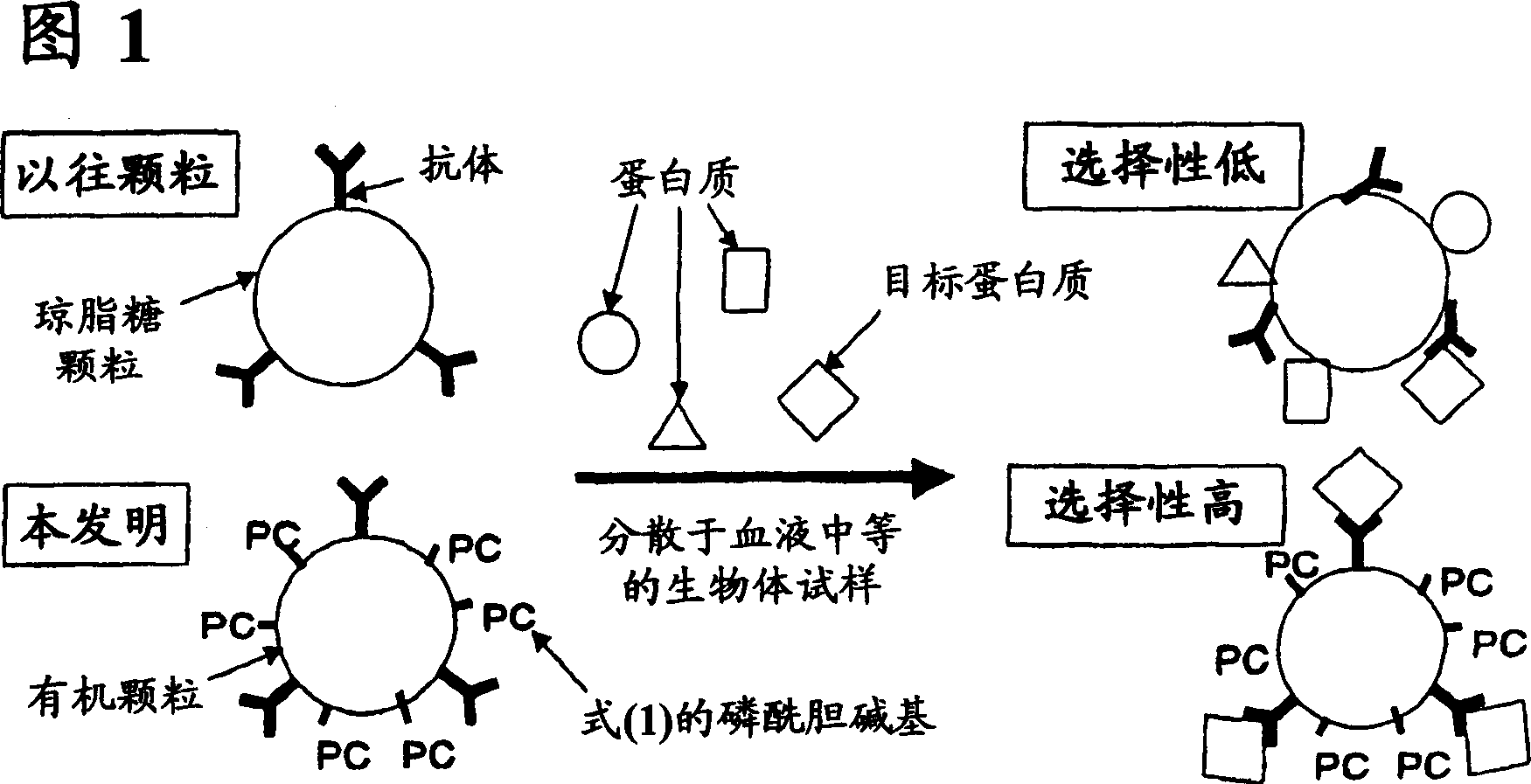

A separation method and affinity technology, applied in the field of affinity separation, can solve the problems that organic particles are prone to agglomeration, require more time for purification, and have low capture efficiency, and achieve prevention of non-specific adsorption, excellent dispersibility, and low purification efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

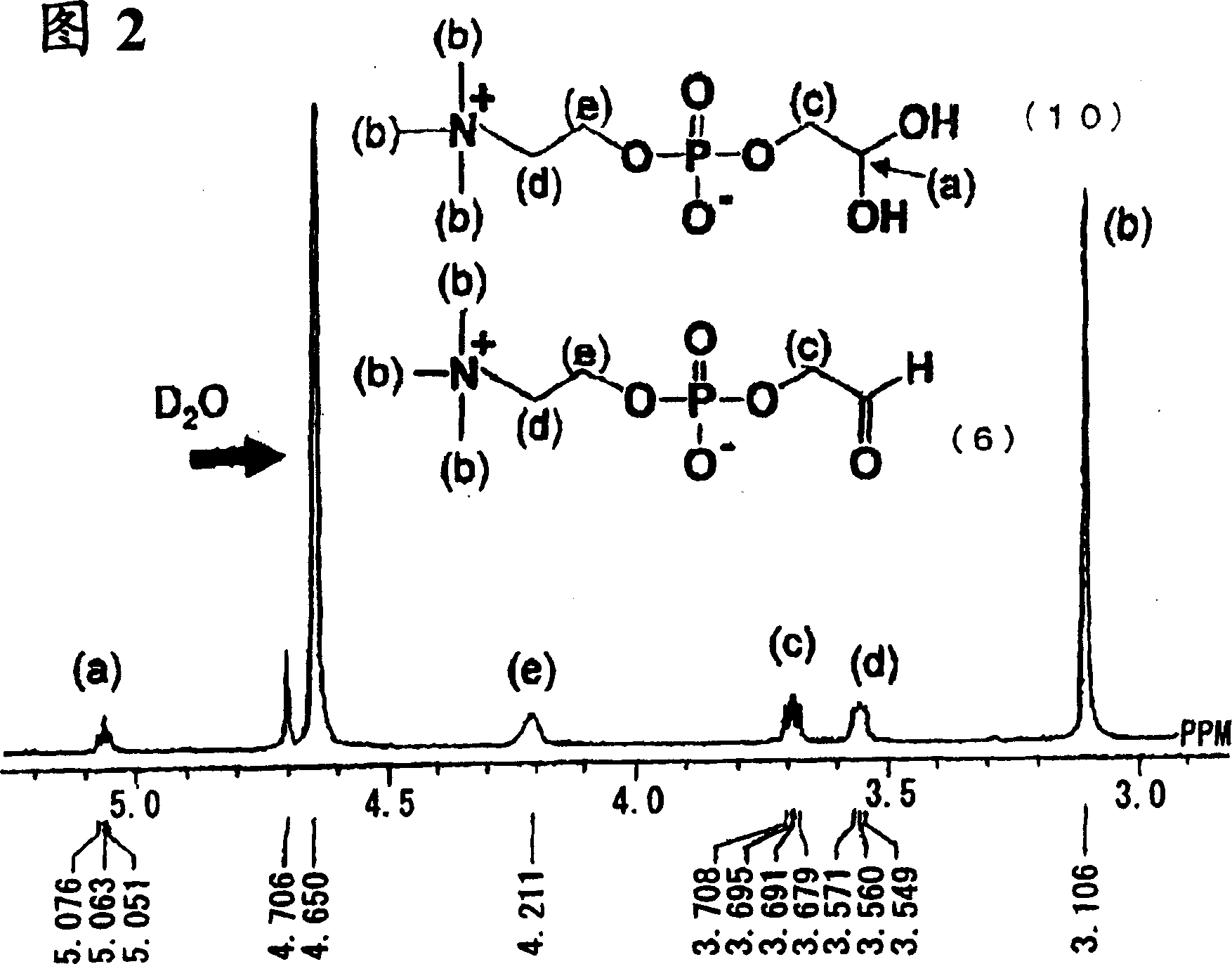

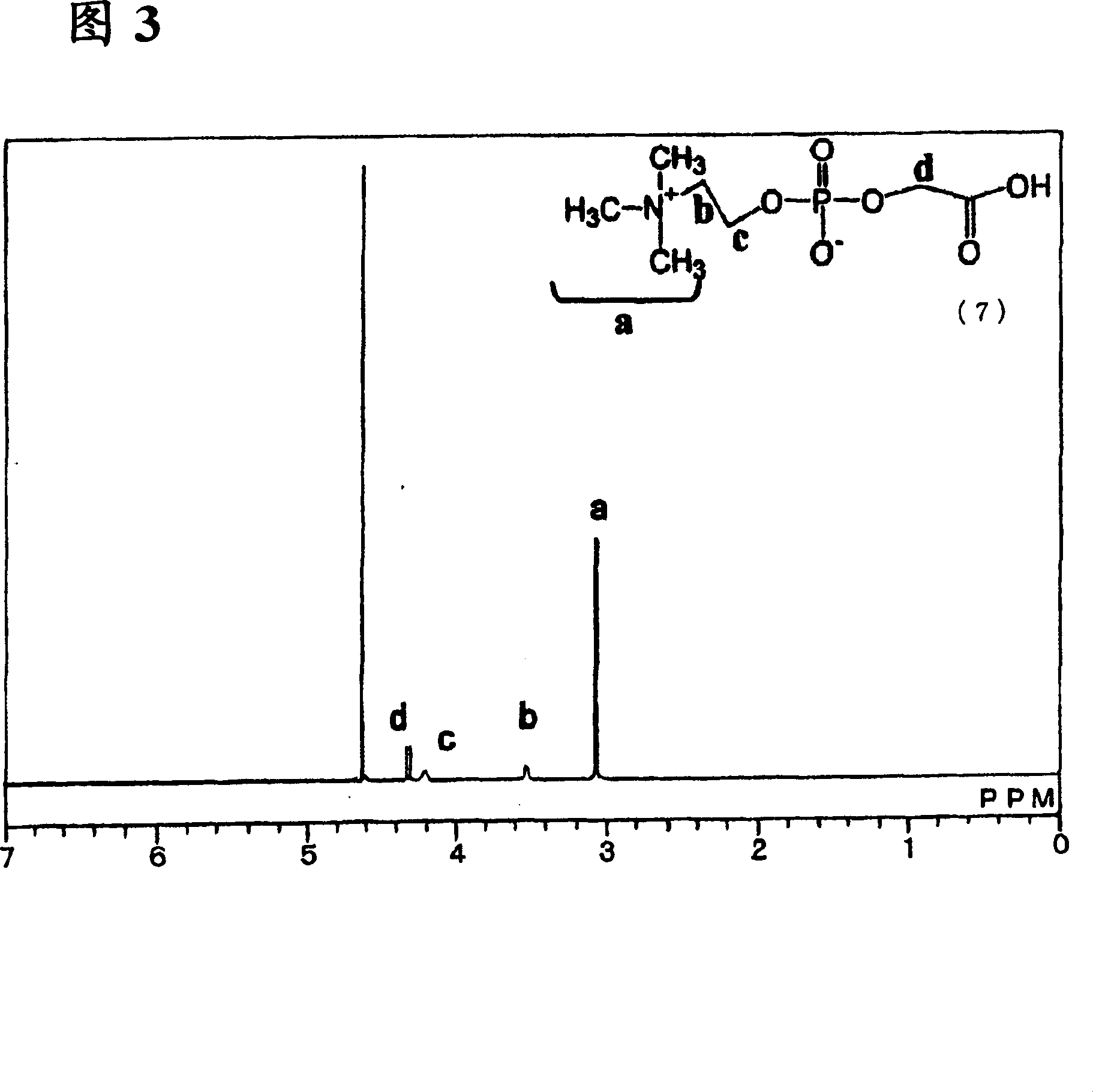

Examples

Embodiment 1

[0228] "Example 1"

[0229] "Affinity Particles"

[0230] The affinity separation method shown in claim 6 is given below. Add 10 mg of the aldehyde body of Synthesis Example 1 to the 2-aminoethyl methacrylate-N-isopropylacrylamide-methylenebisacrylamide particles obtained in 0.1 g of Reference Example 2, stir overnight, then place in an ice-water bath Add 3 mg of sodium cyanoborate to , stir for 6 hours, and then purify and prepare by dialysis in water. To 25 mg of the affinity particles, 1 mL of 8% glutaraldehyde solution and 10 mg of sodium cyanoborohydride (Cianotrihidrohou acid Natrium) for stabilizing the Schiff base were added, reacted at room temperature for 5 hours, and purified by centrifugation with PBS. (5000g) 5 times. Affinity particles according to claim 2 are obtained in which glutaraldehyde is a ligand-binding reactive group or adsorption group. Next, 1 ml of 1 mg / ml bovine albumin or 1 mg / ml human hemoglobin and 10 mg of sodium borohydride were added, reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com