Affinity particle and affinity separation method

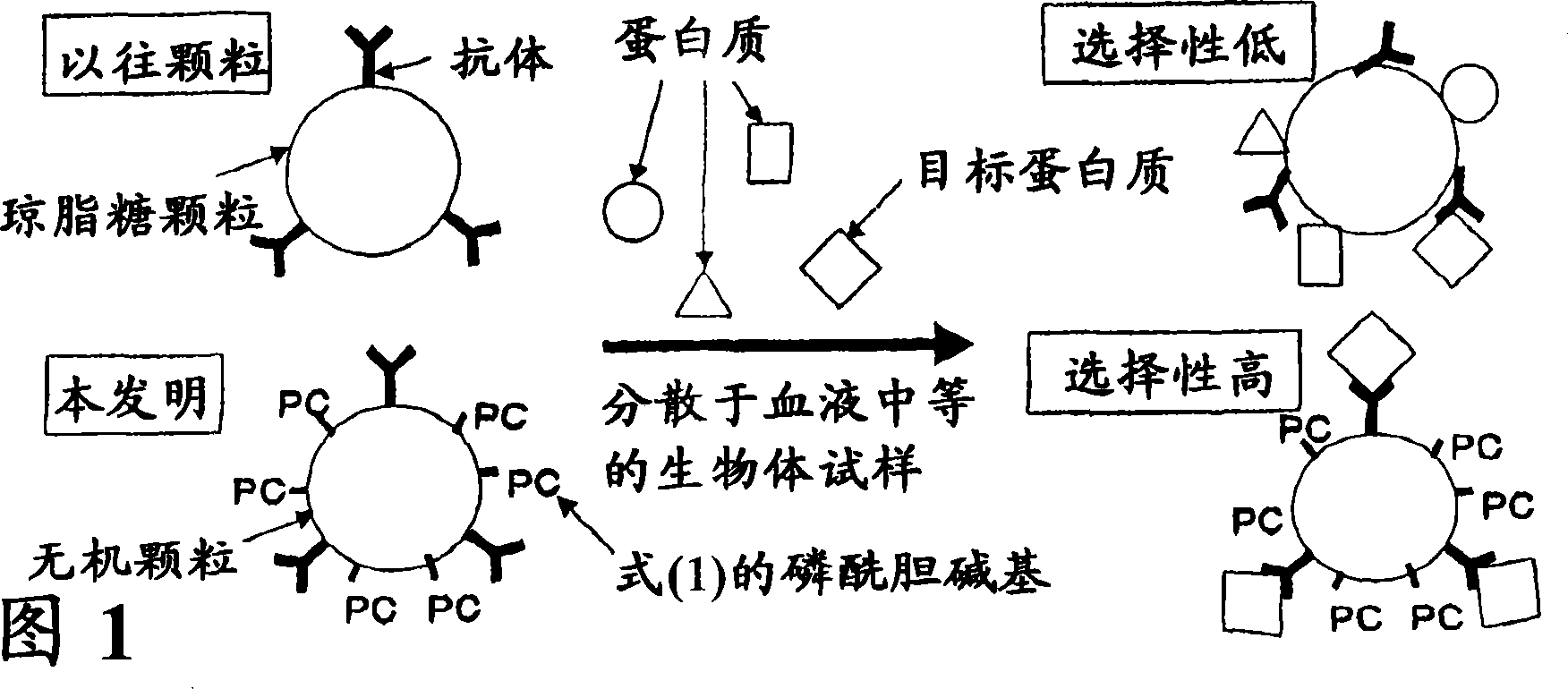

A separation method and affinity technology, applied in the field of affinity particles and affinity separation, can solve the problems of difficult separation of affinity particles, low capture efficiency, carrier disintegration, etc., to prevent non-specific adsorption, high separation selectivity, improve The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0197] The present invention will be further described in detail below according to the examples. The present invention is not limited by these Examples. Phosphorylcholine groups introduced on the particle surface can be confirmed and quantified by FT-IR and elemental analysis.

[0198] "Synthesis Example 1"

[0199] "Aldehyde Compounds Containing a Phosphorylcholine Group"

[0200] Dissolve 6.29 g of 1-α-glycerophosphorylcholine in 210 ml of distilled water, and cool in an ice-water bath. Add 10.23 g of sodium periodate, and stir for 5 hours. The reaction solution was concentrated under reduced pressure, dried under reduced pressure, and the target compound was extracted with methanol. The following compound (6) shows its structure.

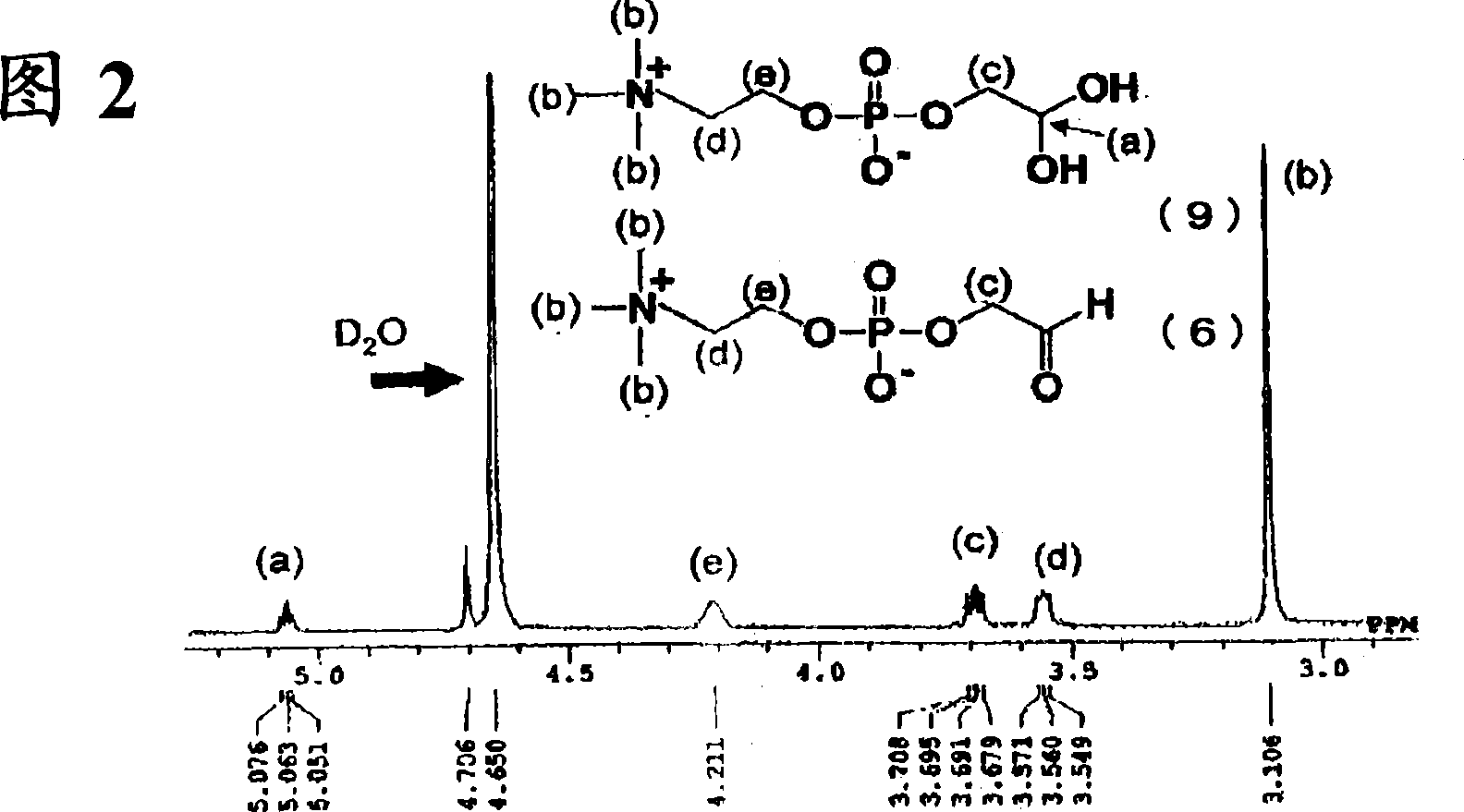

[0201] The 1H NMR spectrum of the compound of formula (6) in heavy water is shown in Figure 2. The compound of formula (6) is in equilibrium with formula (9) in water, so the actual spectrum reflects both formula (6) and formula (9).

[0...

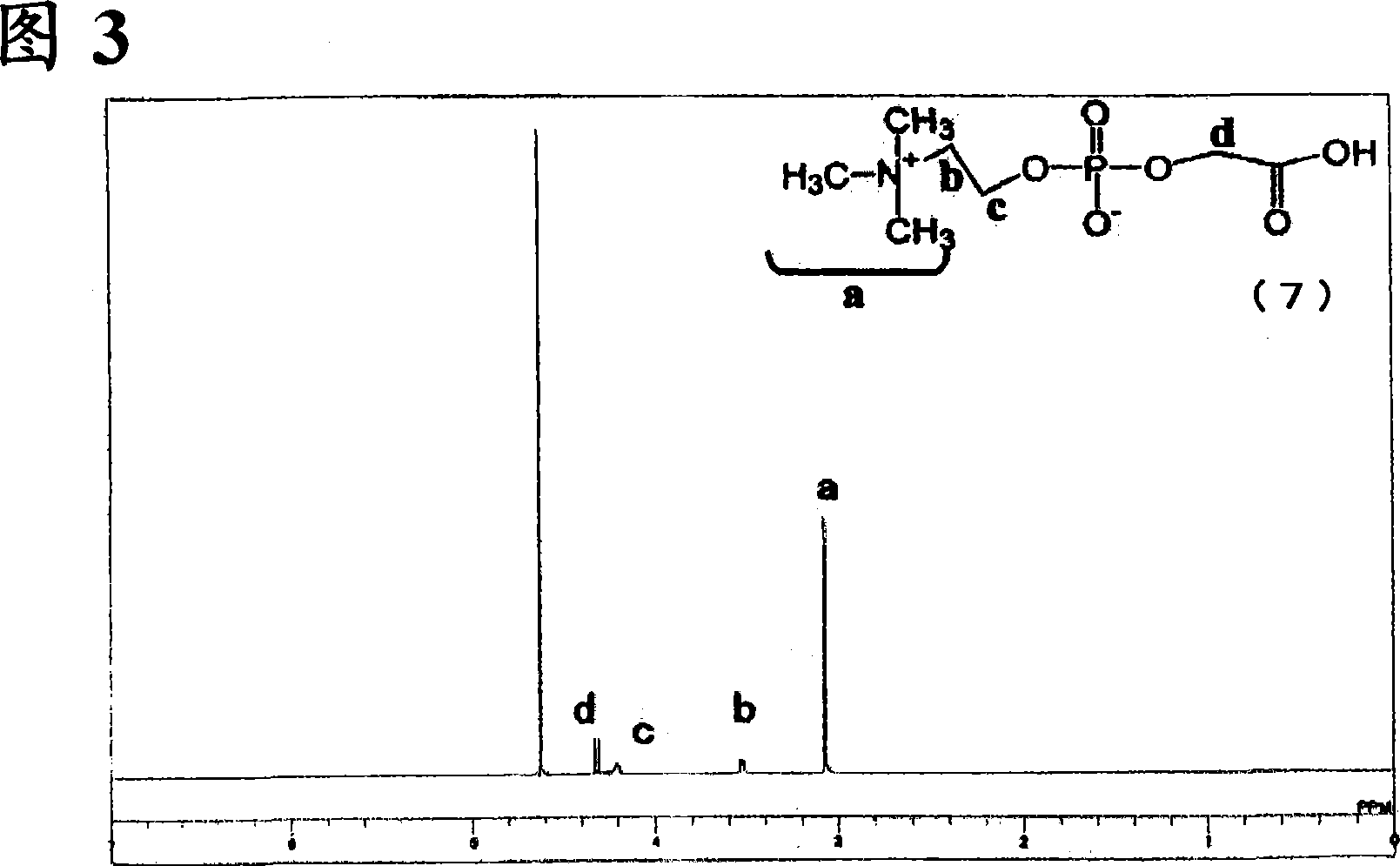

reference example 1

[0231] The 13C-CPMAS spectrum and 13C-PSTMAS spectrum of the PC particles (A) of Reference Example 1 are shown in FIG. 5 . PSTMAS spectroscopy is a method for selectively obtaining the spectrum of free-moving molecular chains, and is widely used for the analysis of modified chains on particle surfaces. In Fig. 5, a spectrum of carbon derived from a phosphorylcholine group was observed at 54.2 ppm.

[0232] In the 31P-CPMAS spectrum of the PC particles (A) of Reference Example 1 shown in Figure 6, the NaH measured as the object 2 PO 4 Peaks were detected at almost the same chemical shift values, thereby confirming the presence of phosphate groups. From the above results, it can be considered that phosphorylcholine groups can be introduced into the surface of the carrier silica gel.

[0233] In FIG. 5 , spectra derived from the carbon of the spacer propyl group were observed around 9 ppm and 23 ppm, and spectra derived from the ethyl group in phosphorylcholine were observed a...

Embodiment 1

[0237] "Example 1"

[0238] "Affinity particles (Af particles (A)) having phosphorylcholine groups and amino groups in the form of covalent bonds on the surface of inorganic particles"

[0239] Take 87.9 μl of methanol solution containing 45 μmol of the compound of formula (10) prepared in Synthesis Example 3 and 50 μl of methanol solution containing 5 μmol of 3-aminopropyltrimethoxysilane, add 47.5ml of methanol, 2.5ml of distilled water, and then add 5g of the average Particle size is 1.5μm, specific surface area is 6m 2 / g of silica gel. The particle dispersion solution was refluxed overnight at 80° C. for coupling. After reflux, the affinity particles (hereinafter referred to as Af particles (A)) according to claim 1 were obtained by centrifugal washing with methanol. The P quantitative measurement of the Af particles (A) treated with the surface modifier of Synthesis Example 3 in the above procedure is shown in FIG. 4 . From this, particles with a PC introduction amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com