Electrochemical machining method in cellular dimple structure

A processing method and honeycomb technology, applied in the direction of electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problems of poor surface quality, high manufacturing cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

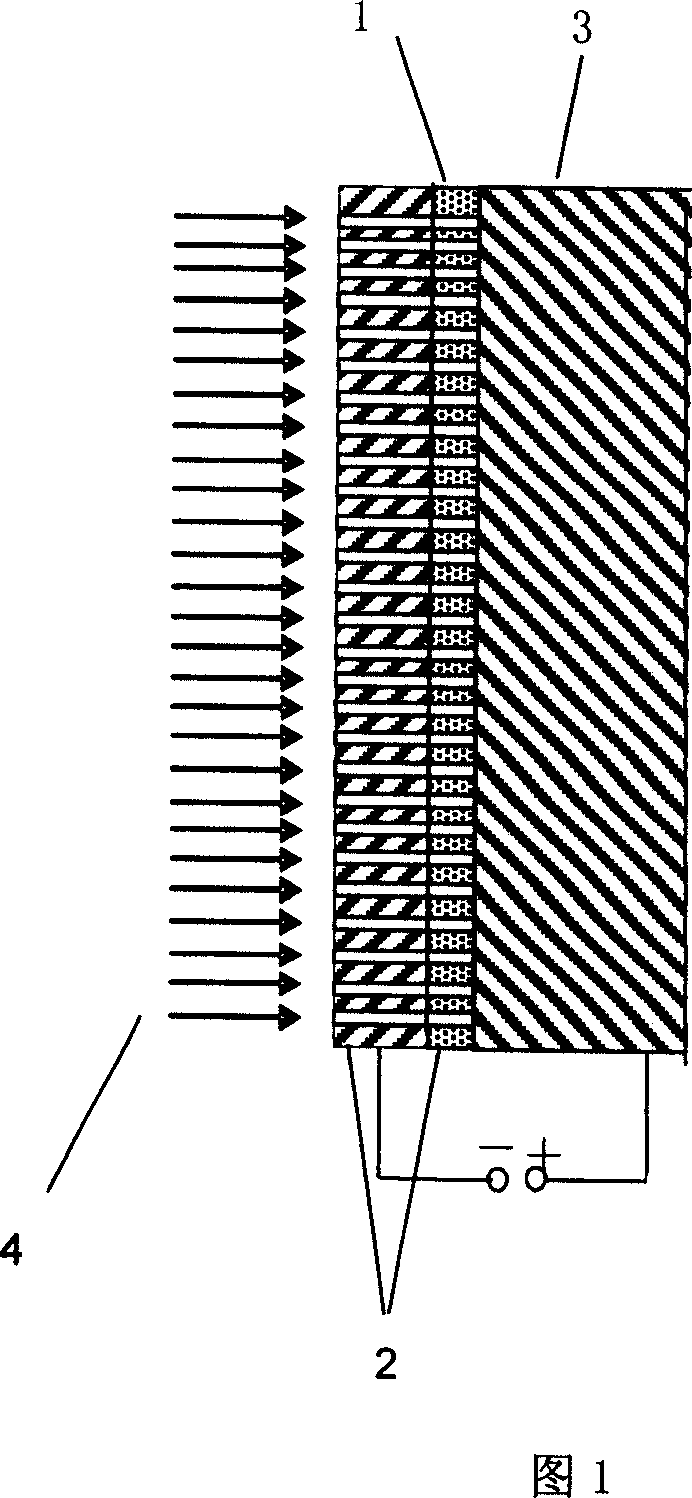

[0013] As shown in Figure 1, the electrolytic machining process of the honeycomb micropit structure. The surface of the tool cathode 2 has a shielding film 1, while the anode 3 does not need any such steps, and it can be electrolytically processed after the tool cathode 2 clamps it. The electrolyte 4 is sprayed to the surface of the tool cathode under the action of the pump, and reaches the area of the tool cathode and the workpiece anode through the inner cavity of the cathode fixture. At this time, the group hole structure is not only the solution inflow channel, but also the solution outflow channel, and the electrolyte Then enter the outflow channel through the flow channel of the cathode holder.

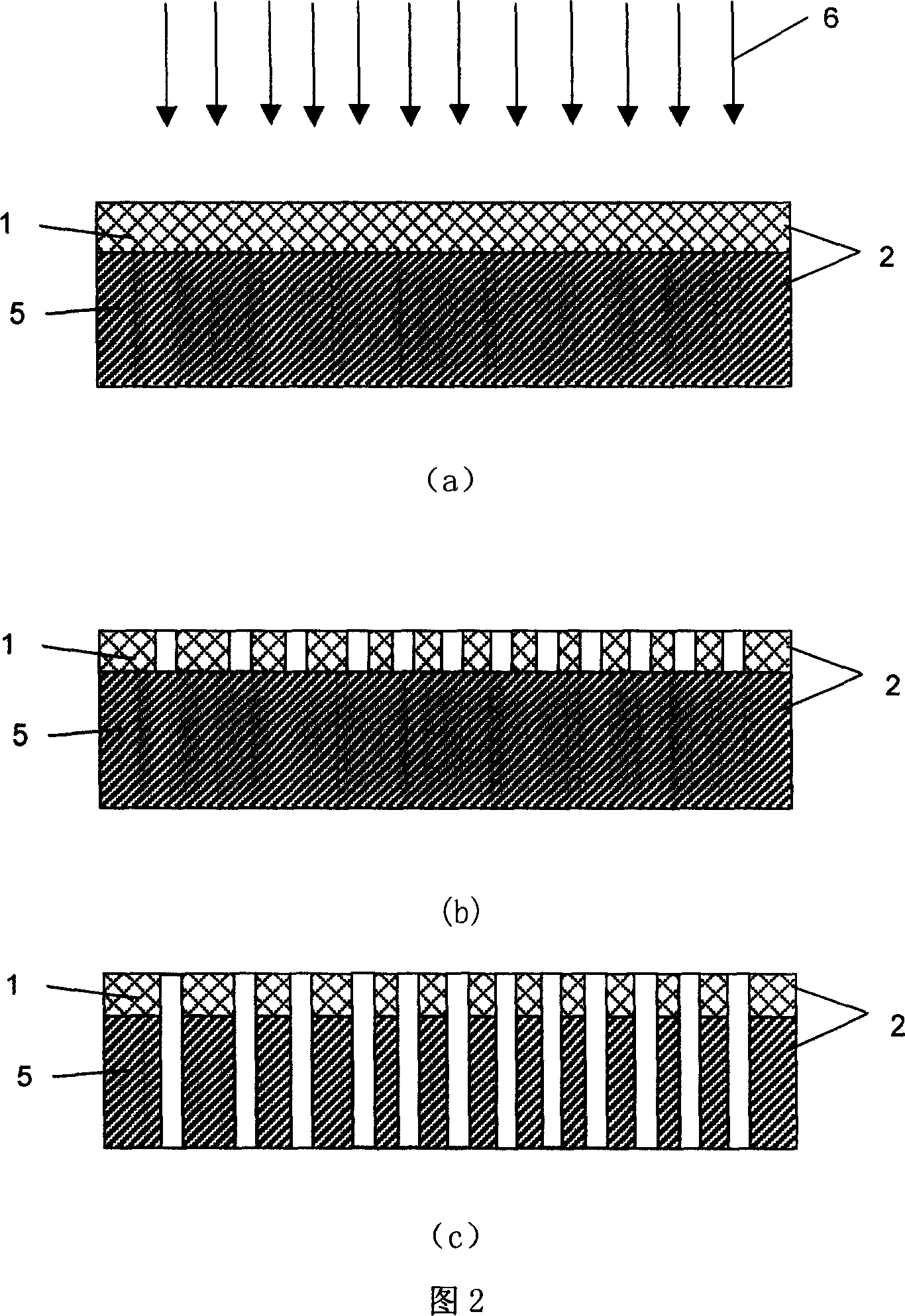

[0014] Figure 2 is a schematic diagram of the tool cathode manufacturing process. The shielding film 1 is coated on the substrate 5, and the pattern shown in Figure 2(b) is formed after photolithography and development. The exposed part of the substrate can be etched. Physica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com