Finned tubular electric heating element, fabricating technique, and fabricating apparatus

A processing technology, electric heating tube technology, applied in the direction of metal processing equipment, heating element shape, etc., can solve the problems of small fin area, poor heat dissipation effect, heat concentration, etc., to achieve large contact area, good convection heat dissipation effect, processing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

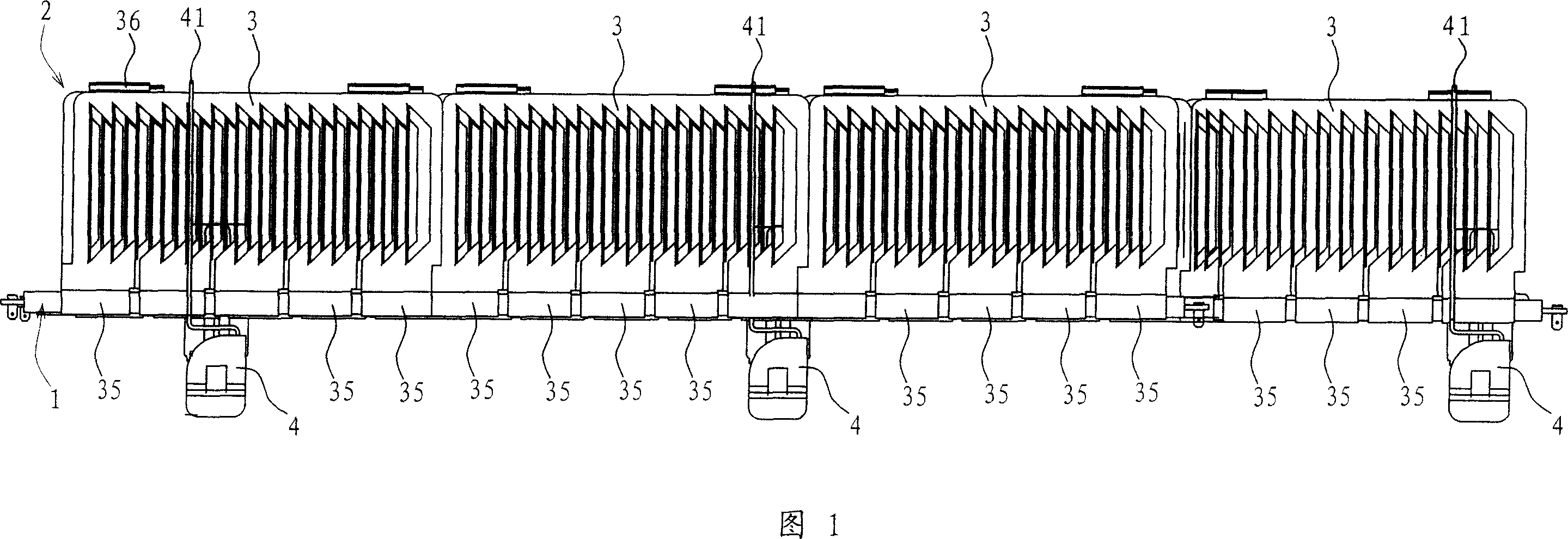

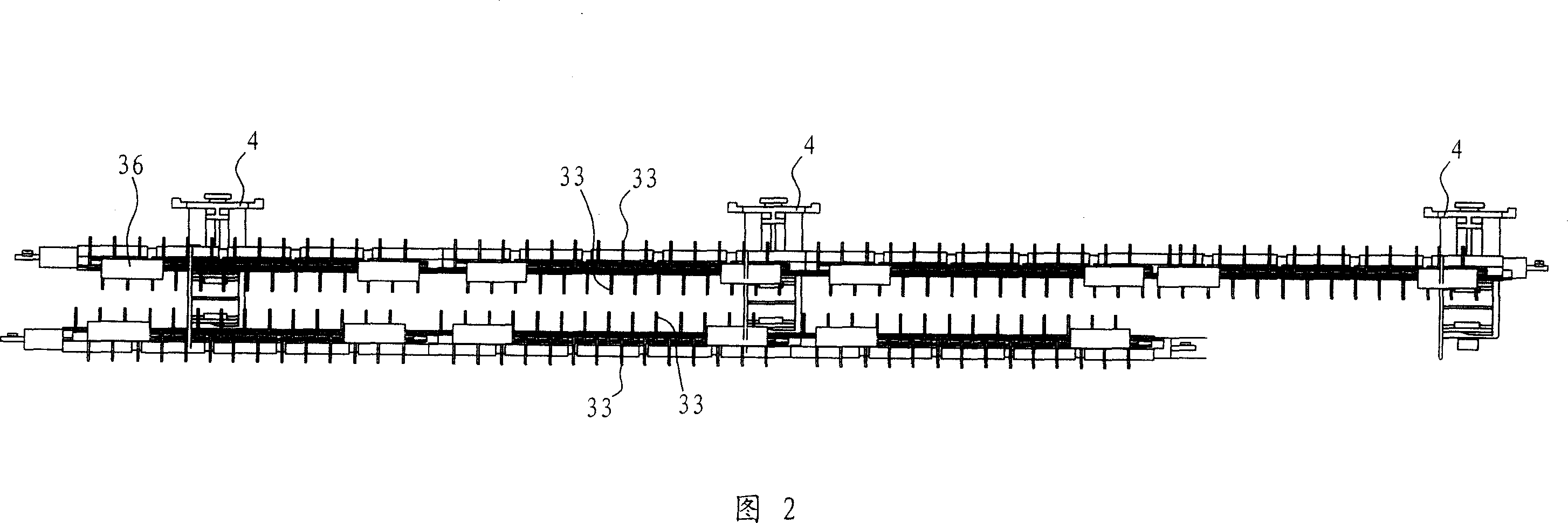

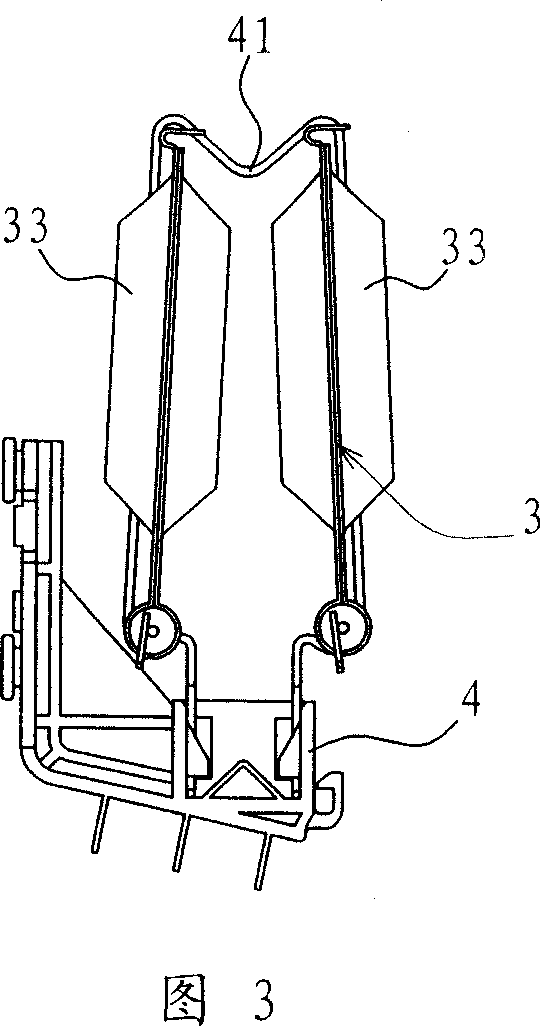

[0032] Referring to Fig. 1 to Fig. 4, a preferred embodiment given in the present invention includes an electric heating tube 1 and a fin expansion board 2, and the fin expansion board 2 is installed on a plurality of bases 4 and passed through a steel wire support 41 be fixed. The fin extension plate 2 is composed of multiple sets of identical fin plates 3 , one end of which tightly wraps the electric heating tube 1 . The fin expansion plate 2 greatly enhances the heat exchange effect of the electric heating tube 1 , improves the thermal efficiency of the electric heating tube 1 , and prolongs the service life of the electric heating tube 1 . The fin plate 3 in the present invention can be made into a standard modular structure, and multiple groups of fin plates 3 are spliced to form the fin expansion plate 2 . Therefore, the electric heating tube 1 and the fin plate 3 can be freely combined according to actual needs and different length requirements, that is, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com