Composition of a solder, and method of manufacturing a solder connection

A technology of composition and solder, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of increased complexity and poor solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

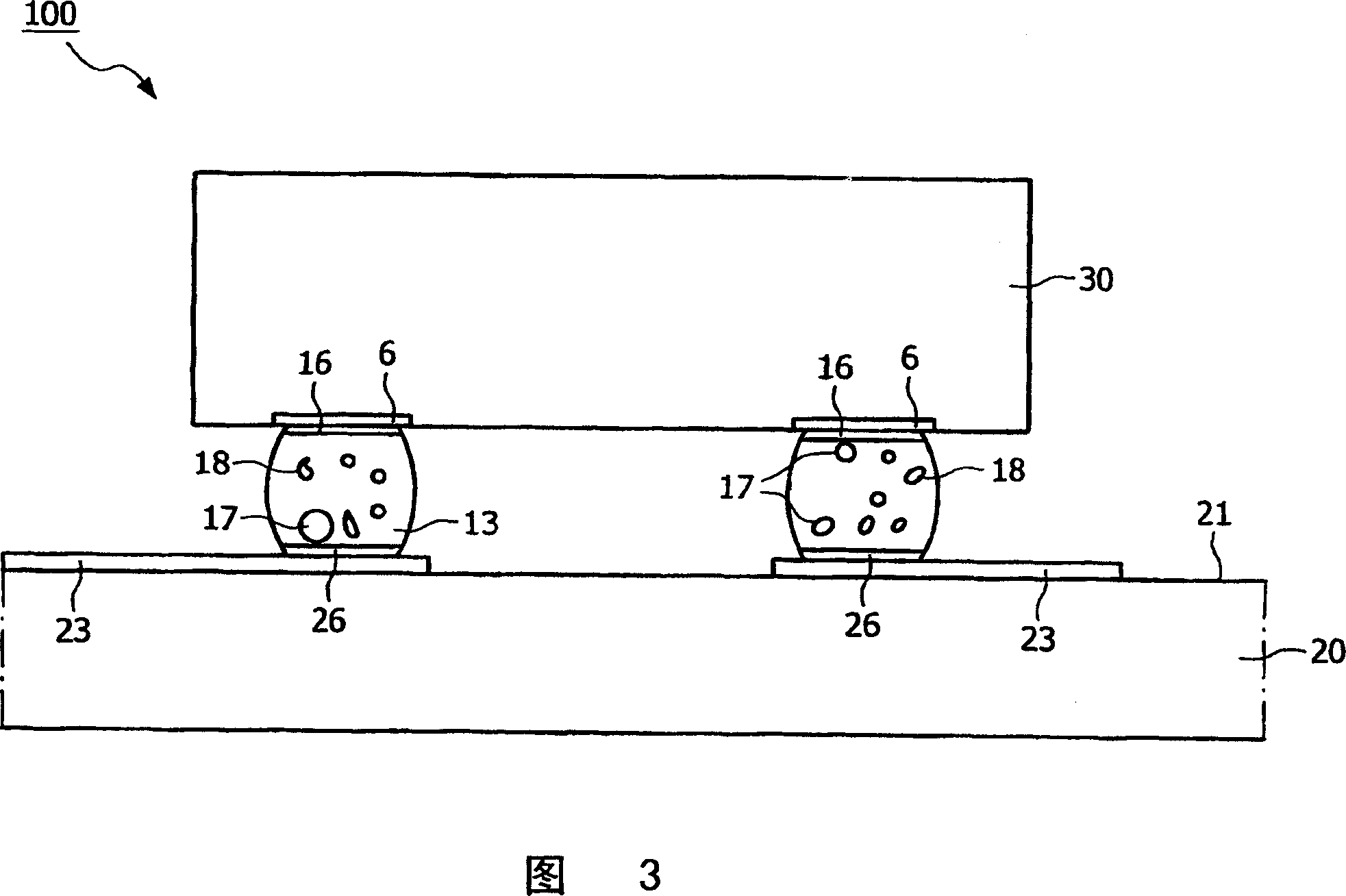

[0049] The drawings are not drawn to scale, and the same reference numbers in different drawings refer to the same parts.

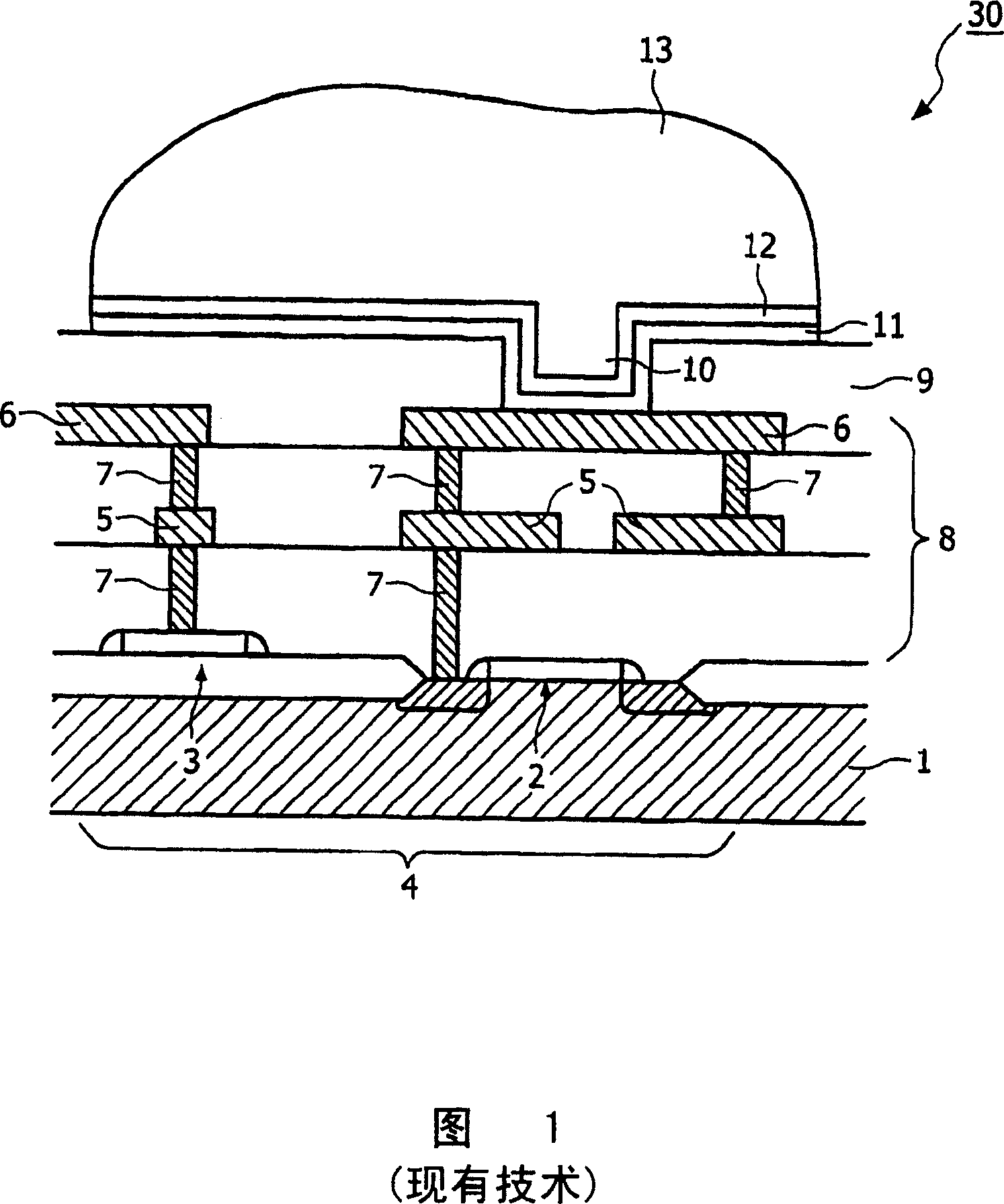

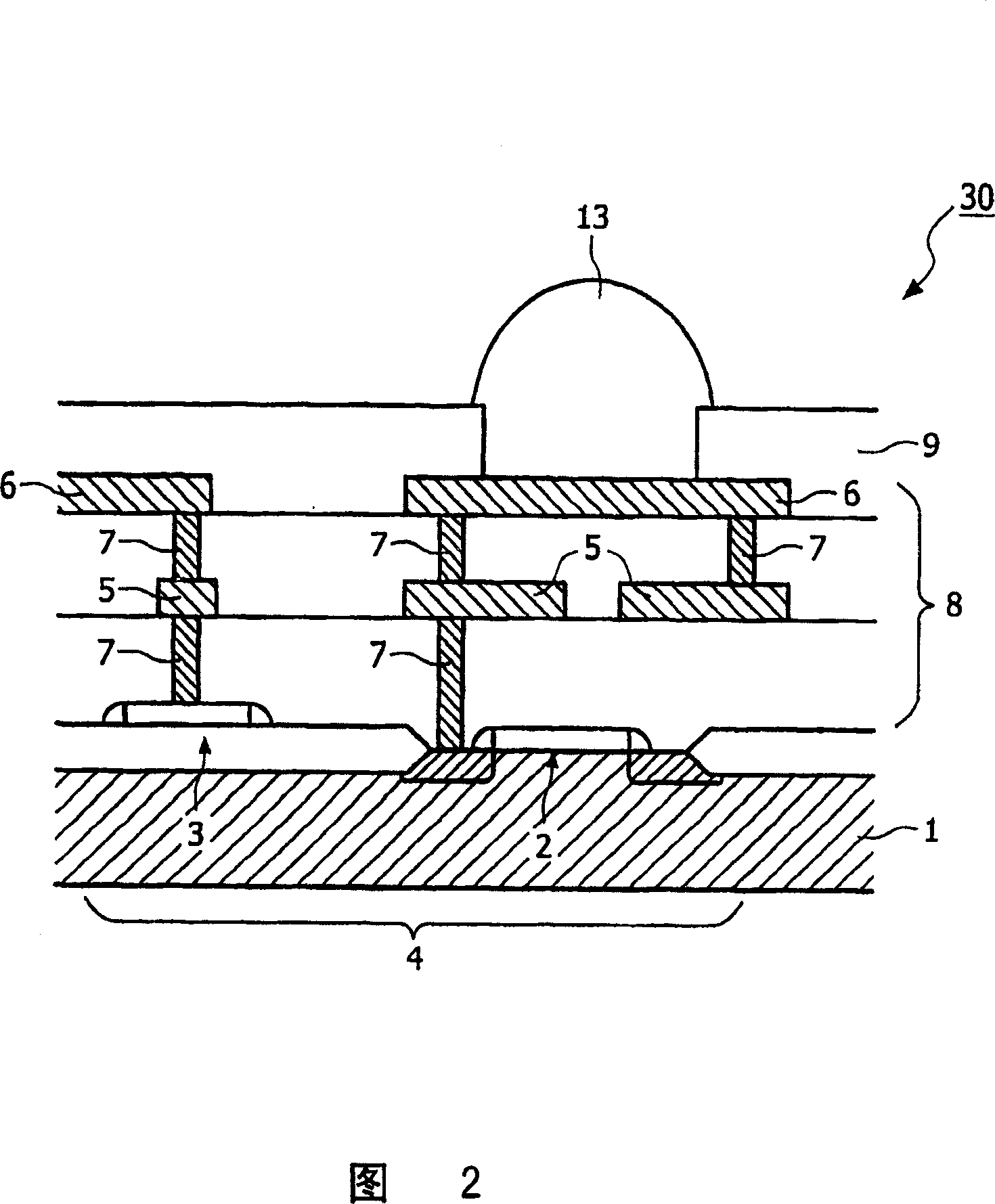

[0050] Figure 1 shows a schematic cross-sectional view of a prior art substrate. The substrate is an integrated circuit device. It includes multiple elements, in this case MOS transistor 2 and polysilicon track 3. The circuit is provided in an active circuit area 4 on the surface of the semiconductor body 1. In the coverage relationship related to the circuit devices 2, 3, an interconnection structure 8 is provided for interconnecting the circuit devices 2, 3 to form a circuit. In this embodiment, the interconnection structure 8 includes a first patterned metal layer 5, a second patterned metal layer 6 and an interconnection via 7. In this example, the patterned metal layers 5, 6 include aluminum or aluminum alloy, such as AlCu. A layer of passivation material 9 is arranged on the interconnect structure 8. The passivation material is for example silicon nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap