Brassieres made from silicon rubber

A silicone rubber and silicone rubber mold technology, applied in bras, clothing, applications, etc., can solve problems such as poor air permeability, large product thickness, and sultry heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

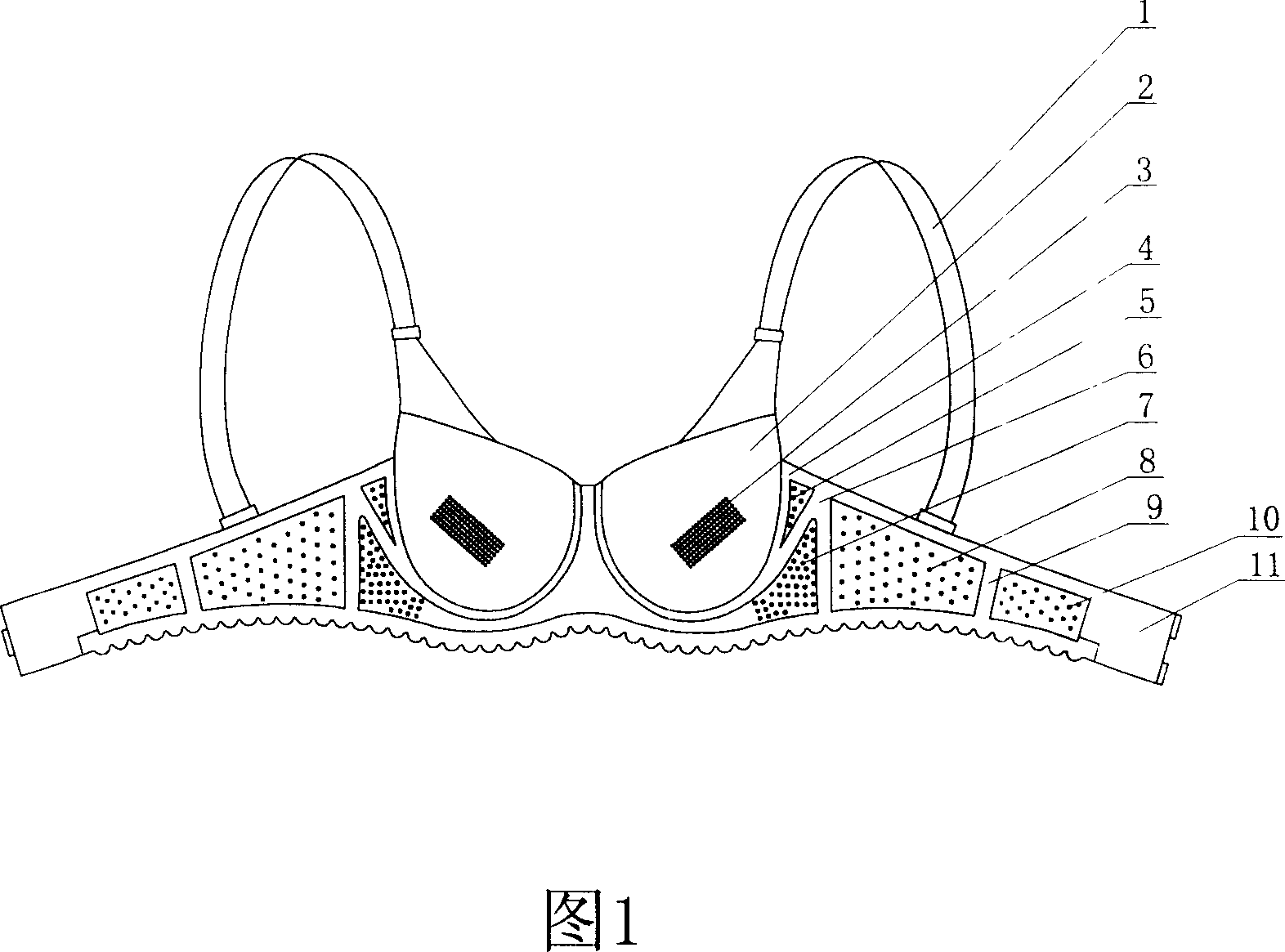

[0012] As shown in Figure 1, a silicone rubber bra includes shoulder straps 1, bra cups 2, and side wings 11. It is characterized in that the whole bra is molded or injected from silicone rubber, and the bra cups 2 have air holes 3. Each bra cup 2 There is an arc-shaped rib 4 on the lower edge of the bra, and an inverted "V"-shaped rib 6 is connected to the arc-shaped rib 4 on the left and right flanks of the bra, and a "1"-shaped rib 9 is arranged. Ventilation holes 5, 7, 8, 10 are evenly distributed between them, and the reinforcing ribs are thickened parts in the integral molding of the brassiere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com