Process for charging titanium tetrachloride for use in preparation of titanium sponge by magnesium method

A technology of titanium tetrachloride and feeding method, which is applied in the field of non-ferrous metal smelting to achieve the effect of ensuring product quality and reducing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

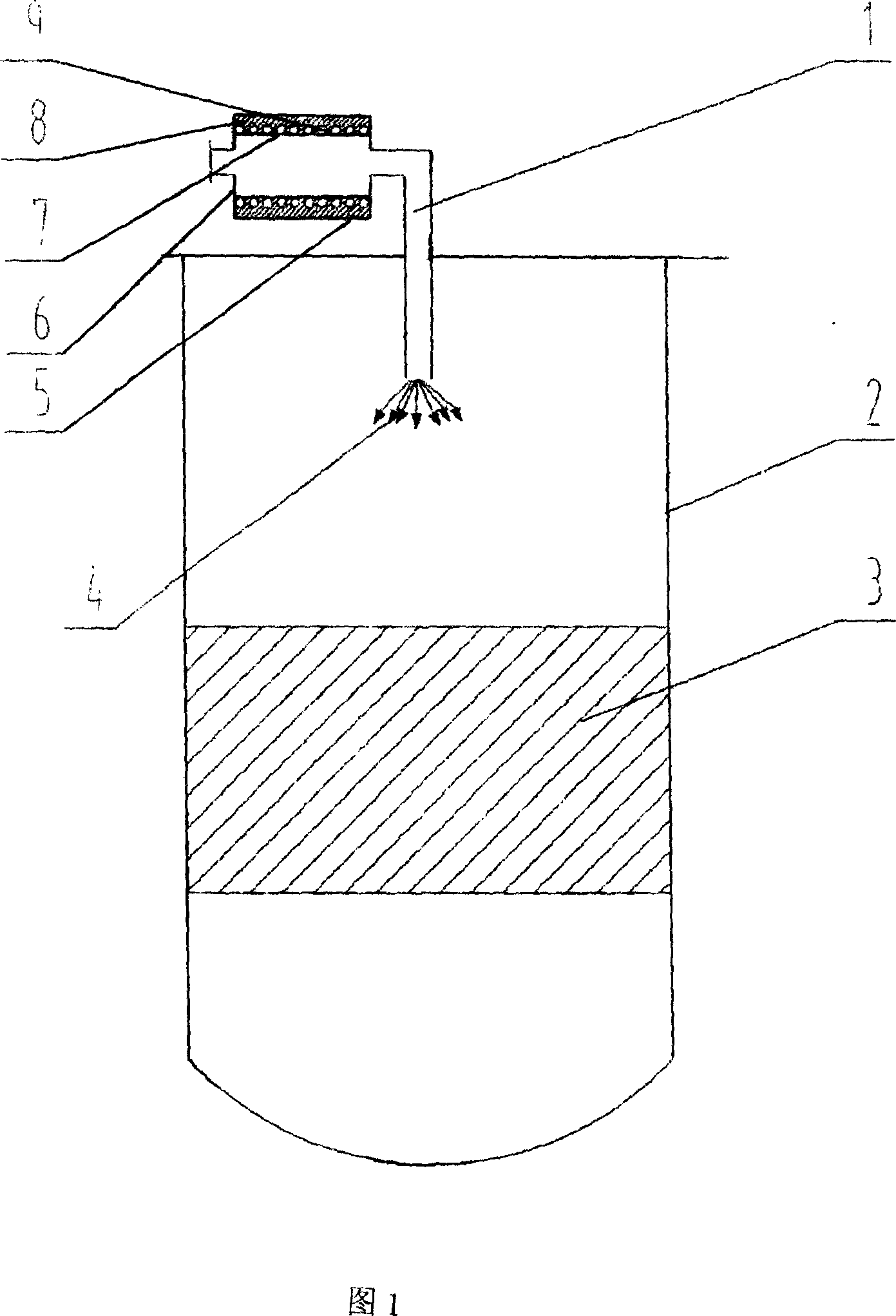

[0015] In a sponge titanium production plant, magnesium sponge is used to produce titanium sponge. The reactor 2 is loaded into a heating furnace, and the metal magnesium 3 in the reactor 2 is in a molten state. As shown in accompanying drawing 1, before titanium tetrachloride feed pipe 1 enters reactor 2, an external heating device is installed. The external heating device includes an outer cylinder body 5, a sealing plate 6, an inner cylinder body 7, a heating element 9 and a refractory insulation material 8. The outer cylinder body 5 is provided with a sealing plate 6 at both ends, and an inner cylinder body 5 is provided inside the outer cylinder body 5. The cylinder body 7 is provided with a heating element 9 near the inner cylinder body 7 , and there is a refractory heat-insulating material 8 between the heating element 9 , the outer cylinder body 5 and the inner cylinder body 7 . During production, the liquid-phase titanium tetrachloride entering from the head tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com