Reinforced concrete bearing platform arranged with diagonal reinforcing steel and method for manufacturing same

A reinforced concrete and concrete technology, applied in the processing of building materials, infrastructure engineering, structural elements, etc., can solve problems such as insufficient use of pull-out steel bars, improve anchorage performance and punching shear resistance, improve ductility, improve The effect of internal force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

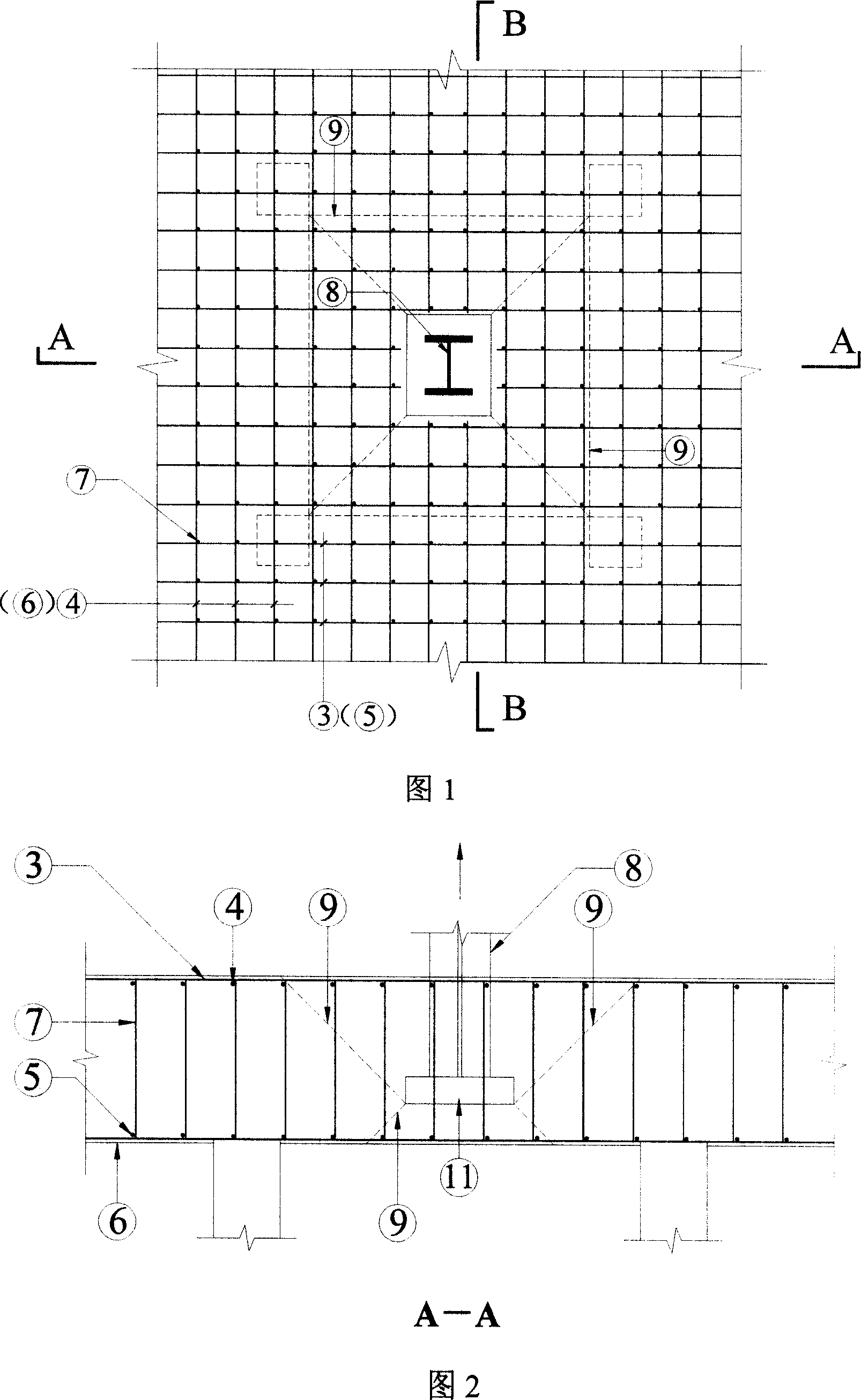

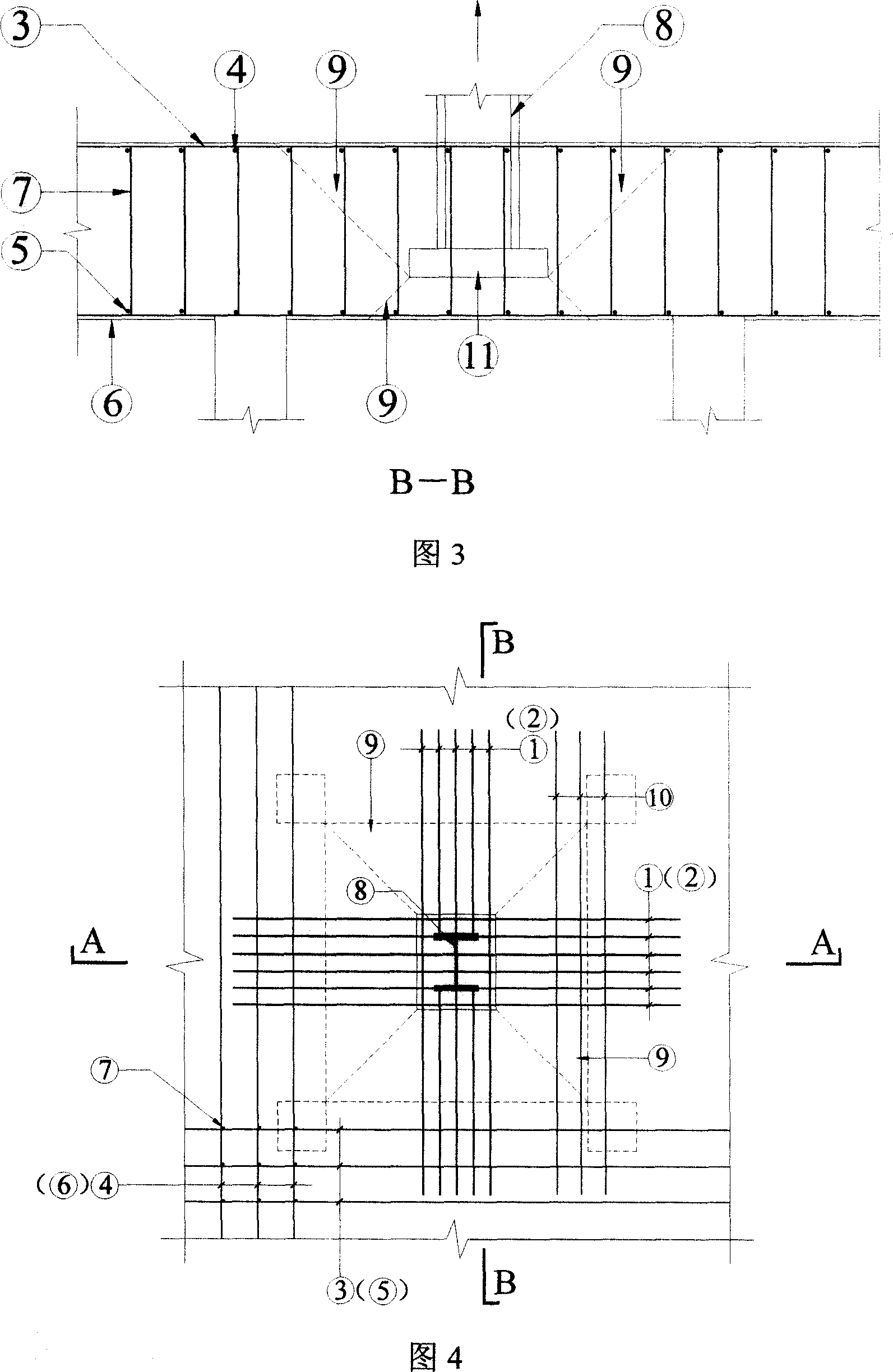

[0031] Figure 4, Figure 5 and Figure 6 show the schematic diagrams of the structural reinforcement of a structural unit of a reinforced concrete cap with oblique reinforcement. The reinforcement of the reinforced concrete cap is that the top surface is arranged with a reinforcement mesh composed of the top horizontal reinforcement 3 and the top longitudinal reinforcement 4; the bottom surface is arranged with a reinforcement mesh composed of the bottom horizontal reinforcement 5 and the bottom longitudinal reinforcement 6. Long layout, reinforcement diameter 12mm, distribution spacing 150mm; on the periphery of the punching failure surface 9, the top reinforcement and bottom reinforcement are supported by vertical tension reinforcement 7; the direction of the inner inclined reinforcement 1 is arranged at an angle of 45° with the horizontal plane , inclined to the steel column foot 8, arranged in 6 layers, the steel bar diameter is 12mm, and the distribution distance is 100mm; t...

Embodiment 2

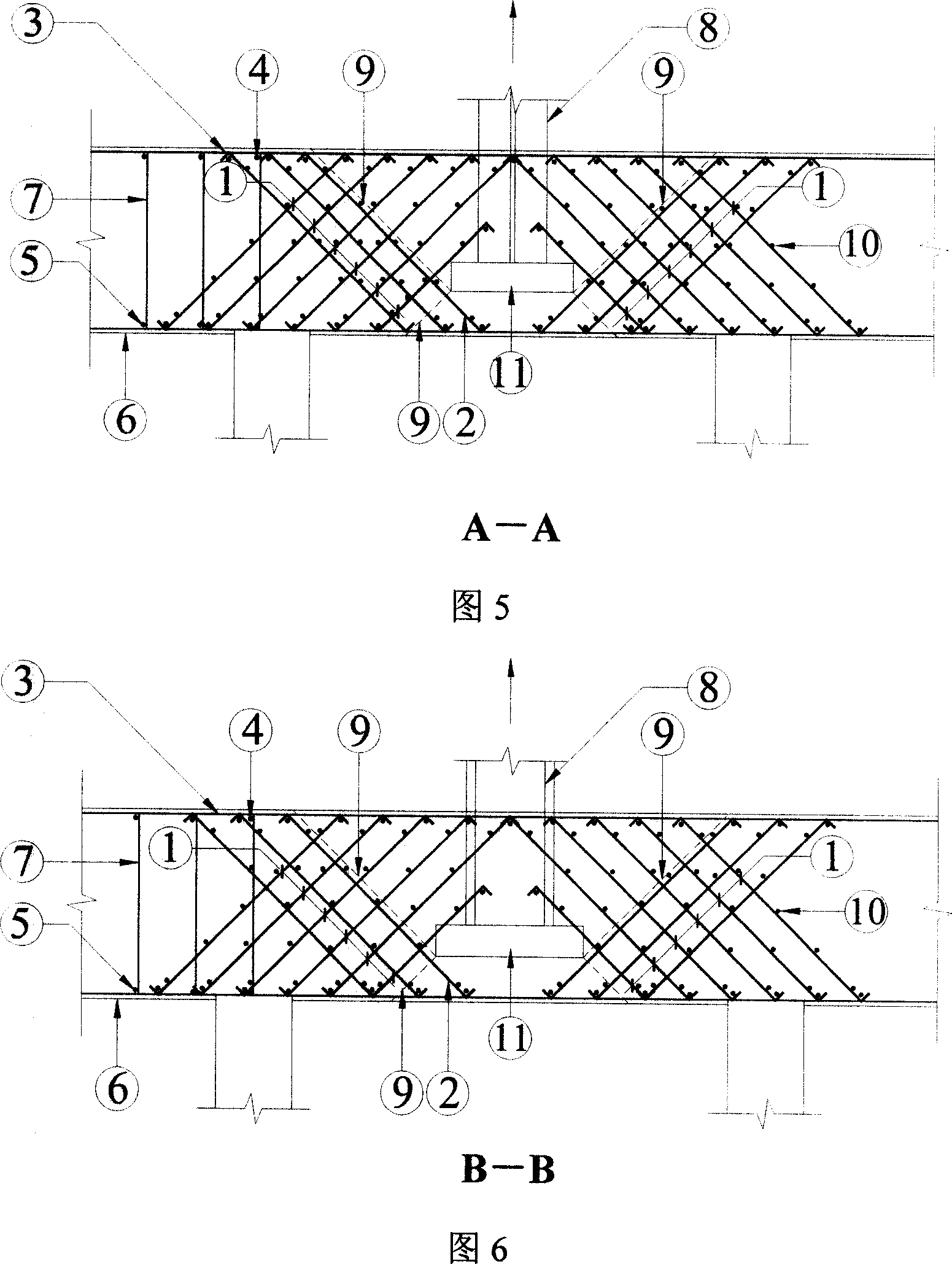

[0033] Figure 7, Figure 8, and Figure 9 show the schematic diagrams of the structural reinforcement of a structural unit of a reinforced concrete cap with oblique pull-resistant steel bars. The top surface and bottom surface of the platform are respectively equipped with reinforcement mesh composed of longitudinal reinforcement and transverse reinforcement. The diameter of the reinforcement is 12mm, and the distribution spacing is 200mm; 7 Tension support; the arrangement direction of the inner inclined steel bar 1 forms an angle of 45° with the horizontal plane, and is inclined to the steel column foot 8, and is arranged in three layers, the diameter of the steel bar is 12mm, and the distribution distance is 200mm; form an included angle of 45°, away from the steel column foot 8 and tilt outwards, arranged in two layers, the diameter of steel bars is 12mm, and the distribution spacing is 200mm; Each end of the steel bar is provided with a hook, which is respectively hung on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com