A steam atomizing film-pressing system

A membrane system, vapor pressure technology, applied in the direction of electrical components, printed circuit manufacturing, circuits, etc., can solve problems such as circuit breaks or gaps in the substrate, and achieve the effects of increasing coverage, strong practicability, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

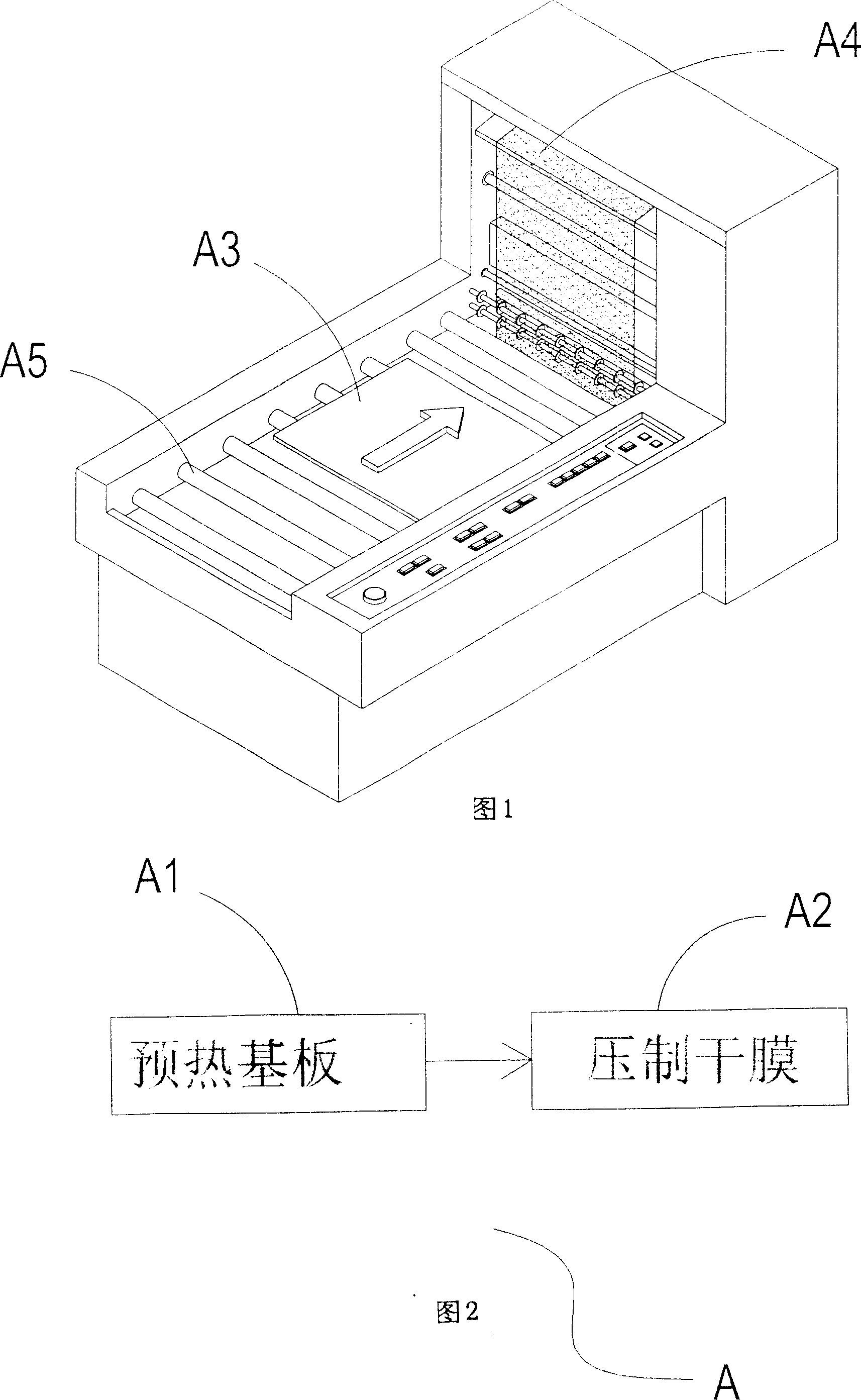

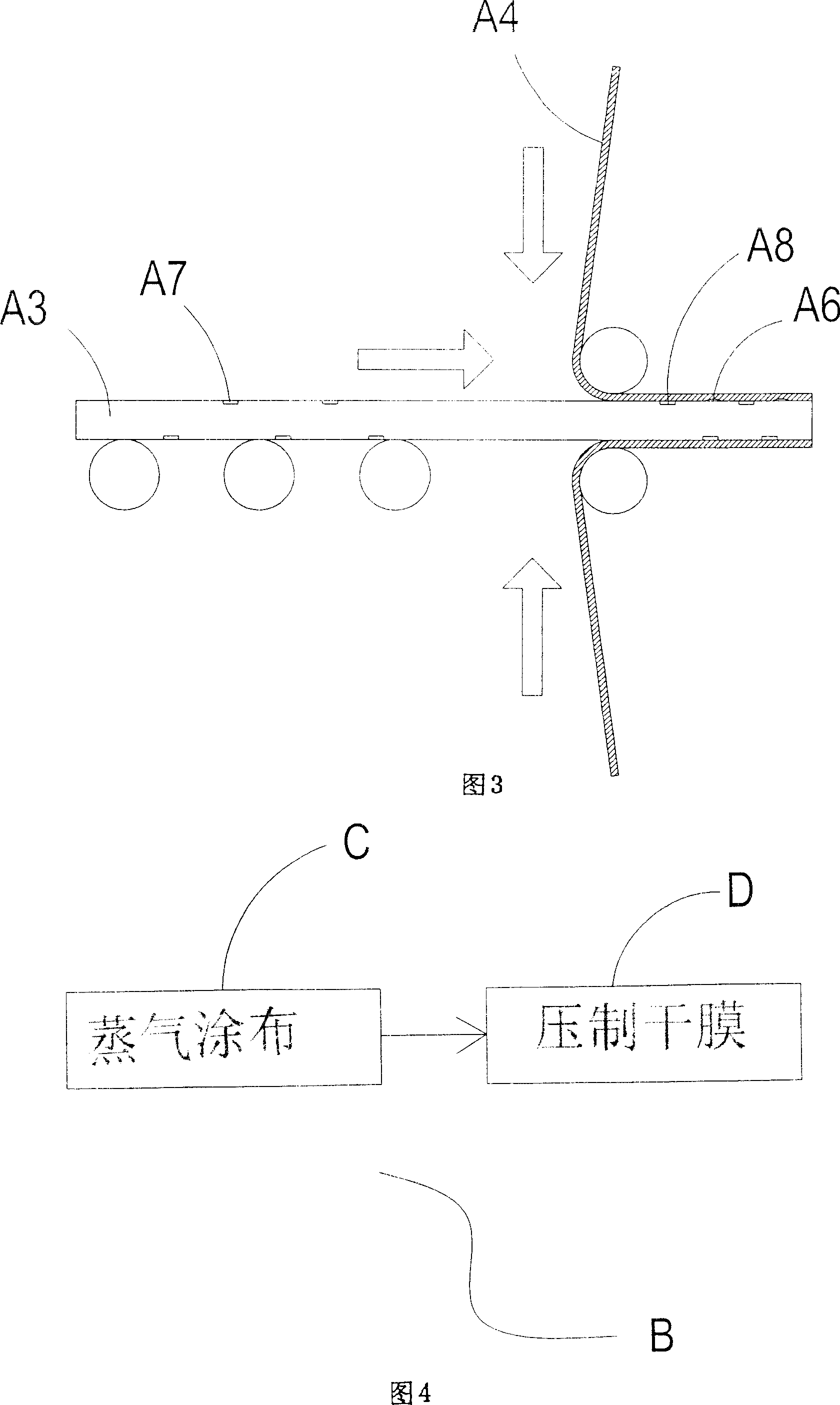

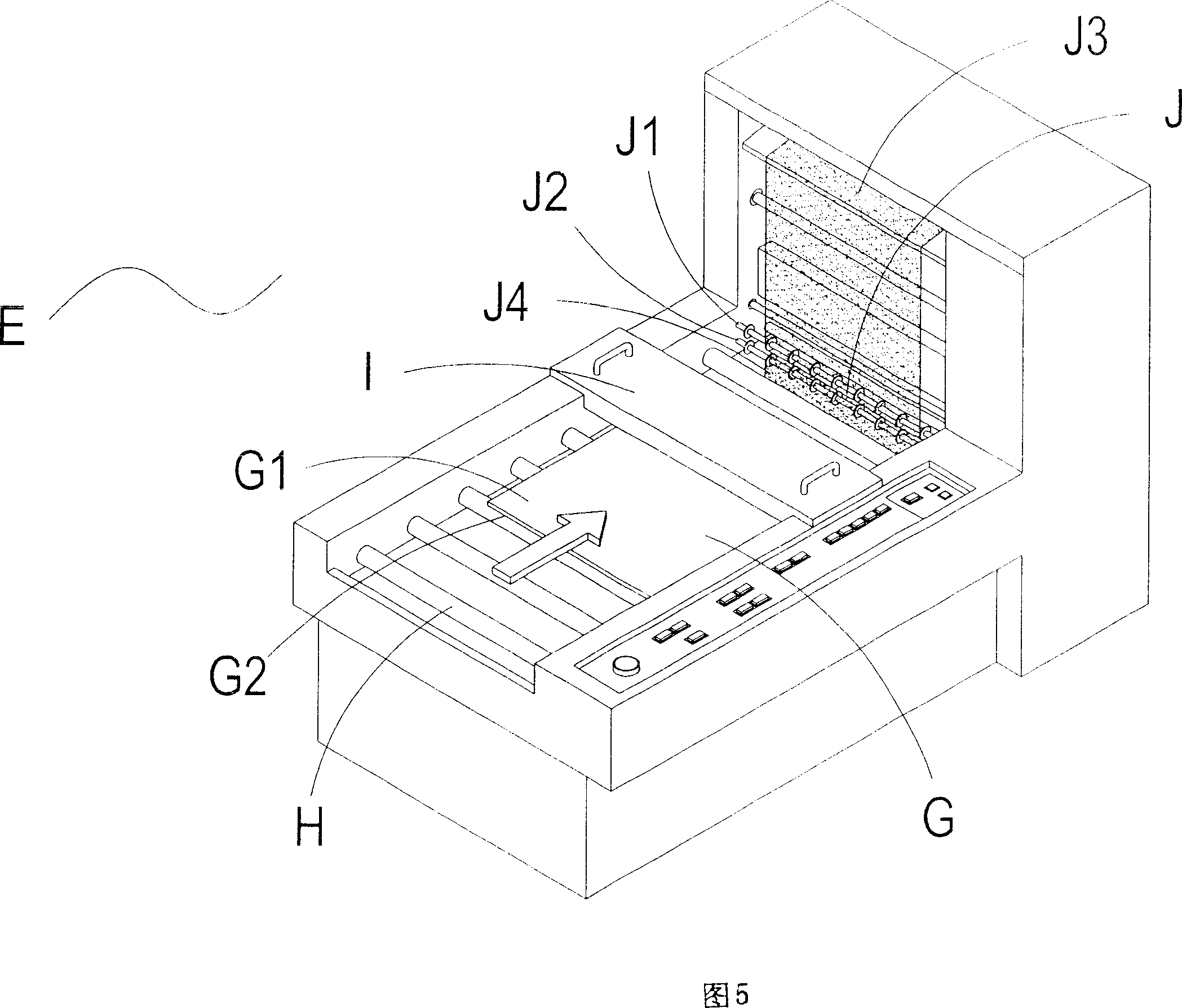

[0012] As shown in accompanying drawings 4 and 5, the lamination process B of the present invention includes steam coating C and pressed dry film D. In the steam coating C, the substrate G is first placed on the transport roller H, and the transport roller H Driven to bring the substrate G to the steam coating device I, wherein the steam coating device I atomizes the steam moisture and coats the upper substrate G1 and the lower substrate G2 to complete the steam coating C, and finally enters the pressed dry film D , the substrate G enters the lamination entrance J, so that the substrate G presses the upper dry film J3 and the lower dry film J4 on the upper substrate G1 and the lower substrate G2 of the substrate G by the upper roller J1 and the lower roller J2, and the substrate G is completed. Lamination process B.

[0013] As shown in accompanying drawings 5 to 9, when the substrate G is transported to the steam coating device I by the transport roller H on the lamination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com