Method of minimisation of PAH emissions using particle filters and filter thereof

A particle filter and exhaust gas emission technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problems of PAK combustion temperature cannot be reached, poor filtration effect, etc., and achieve the effect of reducing PAK emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

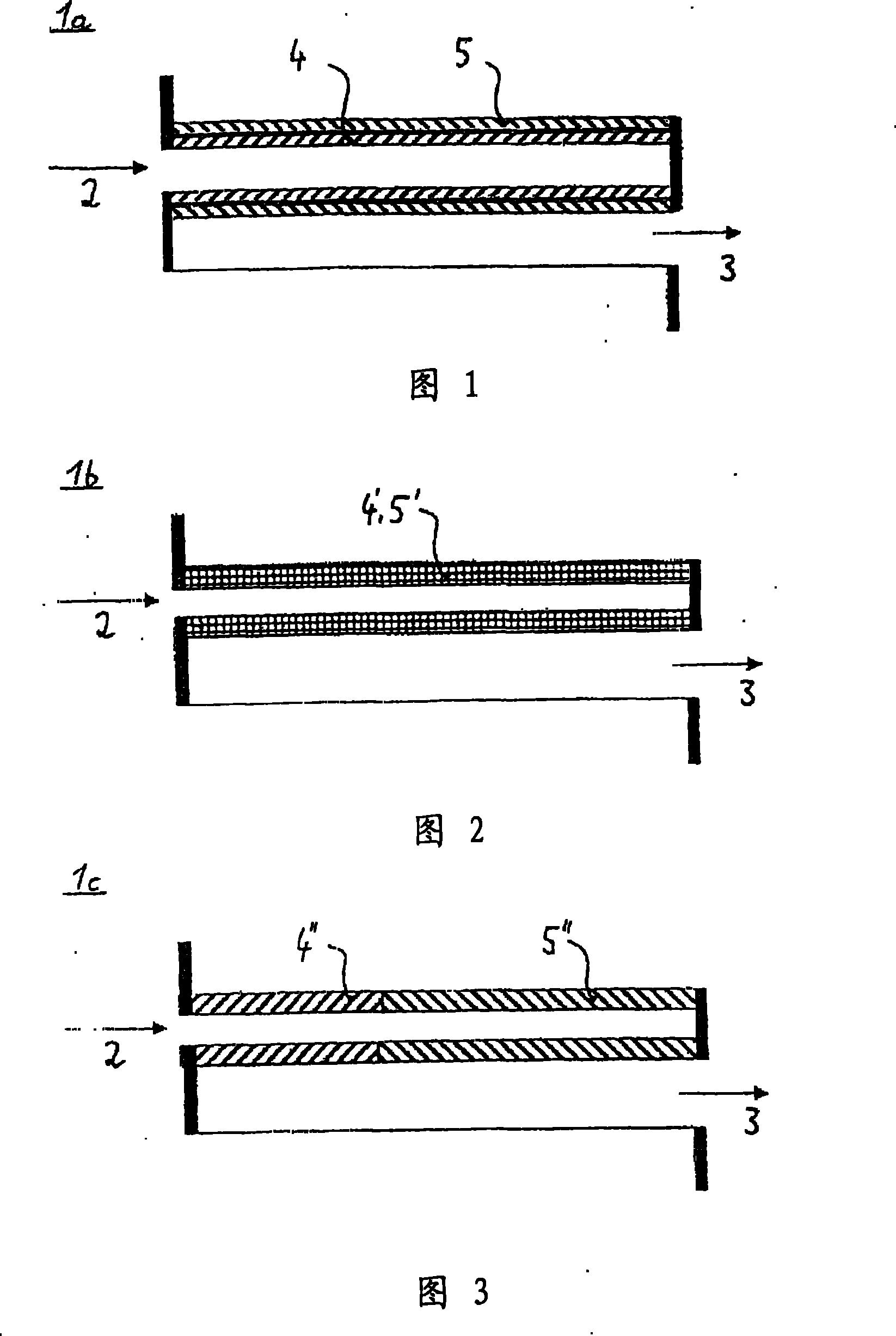

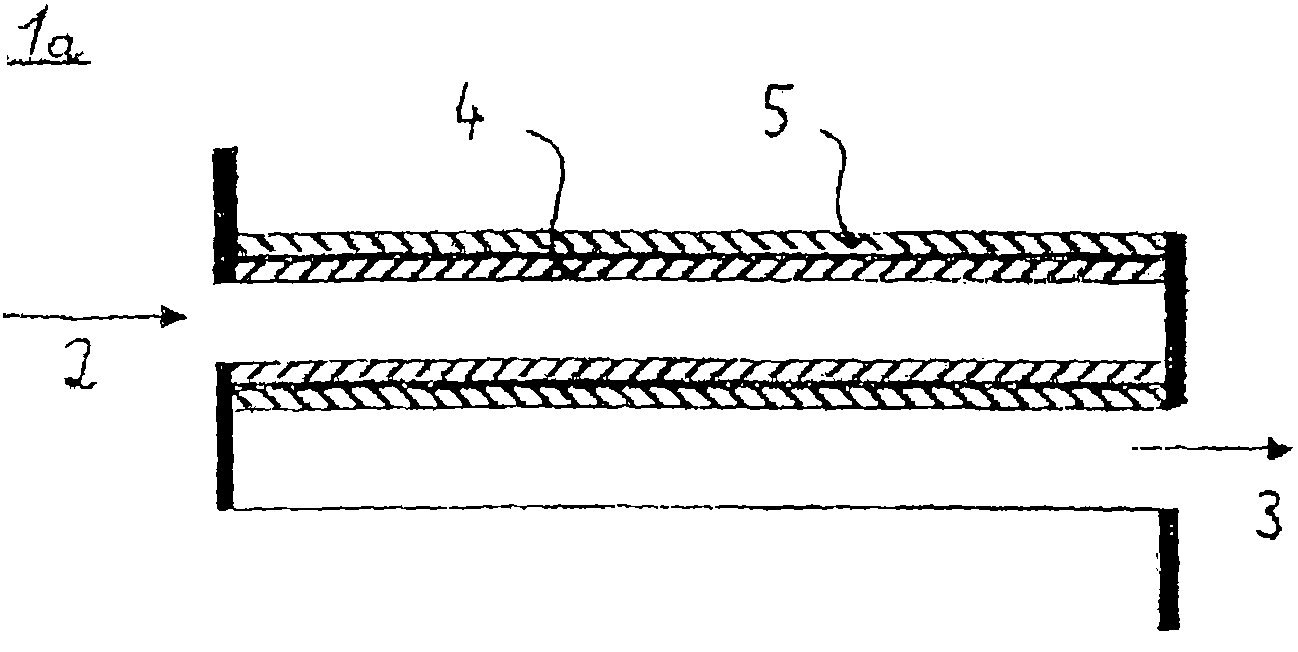

[0044] The diesel particulate filter 1a according to FIG. 1 for carrying out the method according to the invention has an adsorption layer 4 on the exhaust gas 2 inflow side, whereas an oxidation coating 5 is provided on the exhaust gas 3 outflow side of the diesel particulate filter 1a. All exhaust gases therefore flow first through the adsorption layer 4 and then through the oxidation coating 5 of the diesel particulate filter 1a.

[0045] According to FIG. 2, the diesel particulate filter 1b is equipped with a composite coating which is arranged between the incoming exhaust gas 2 and the outgoing exhaust gas 3 and which combines the adsorption layer 4' and the oxidation coating 5'.

[0046] According to Fig. 3 on the diesel particulate filter 1c, according to a kind of prescribed arrangement along the longitudinal dimension of the diesel particulate filter 1c, apply the coating according to the present invention, from the aspect of flowing into the exhaust gas 2, set the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com