Apparatus and method for damping or preventing partial vibration of paper machine

A vibration damping device, technology for paper machines, applied in the direction of paper machines, textiles and papermaking, papermaking, etc., capable of solving problems such as unprepared connections and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

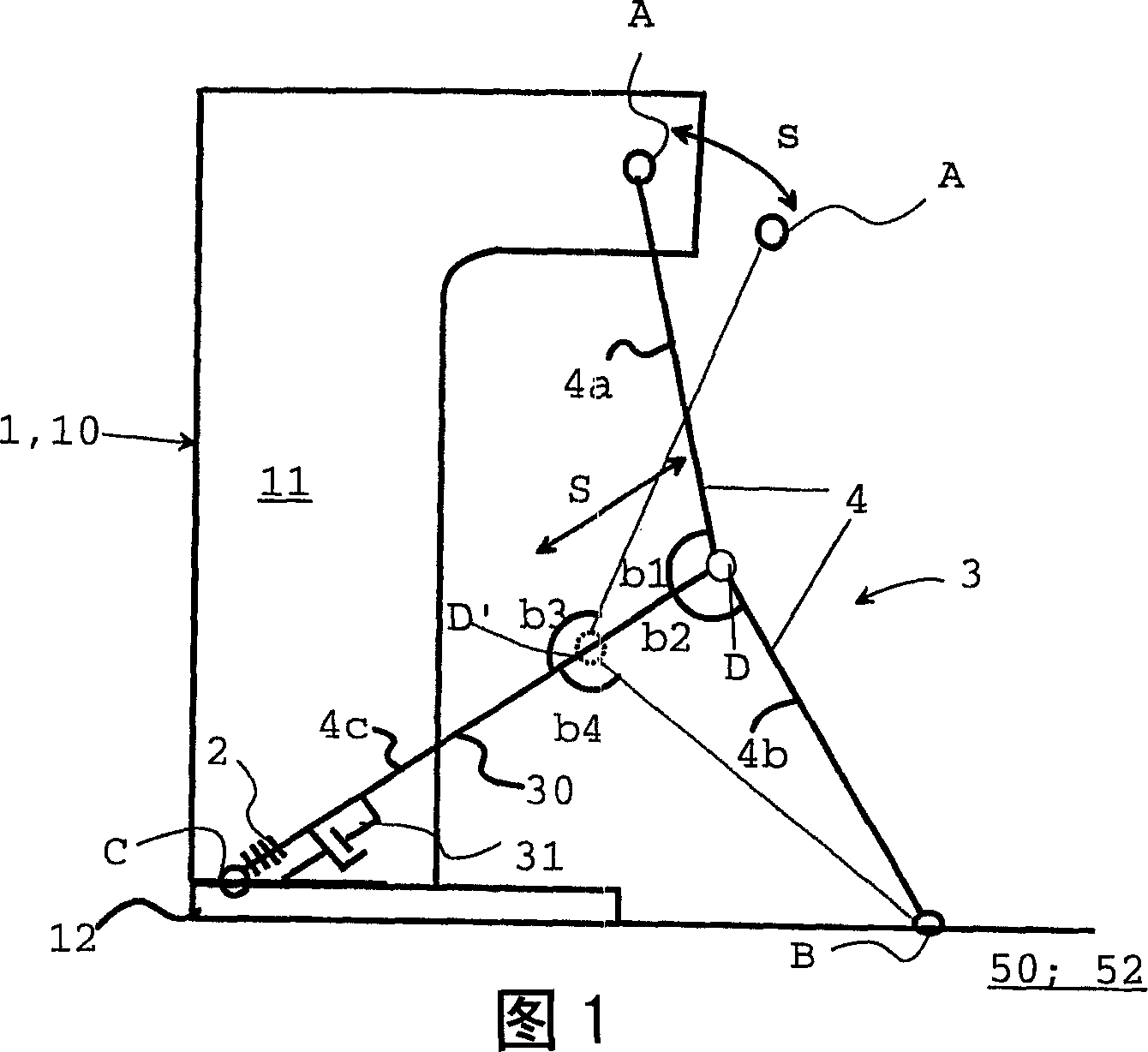

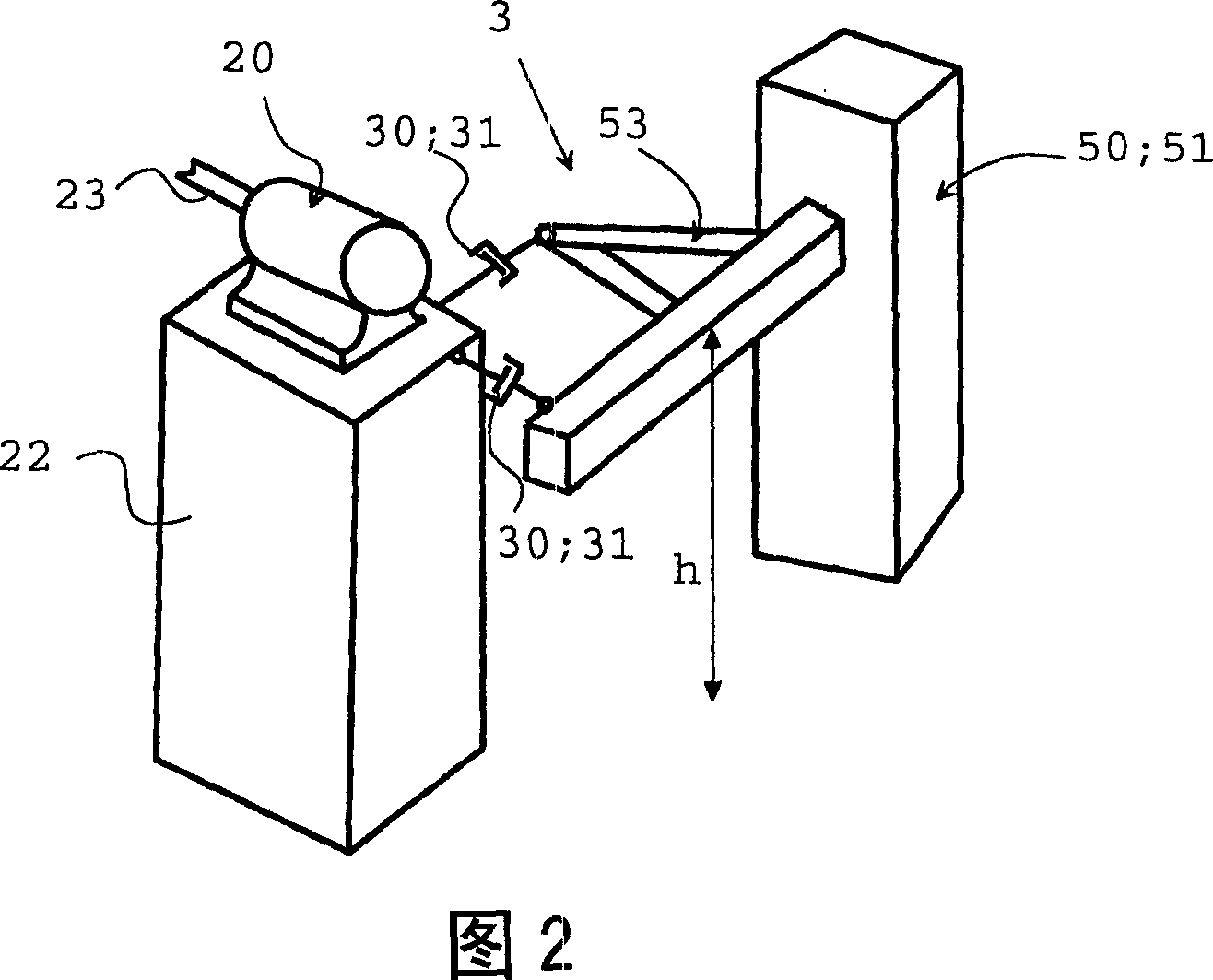

Embodiment Construction

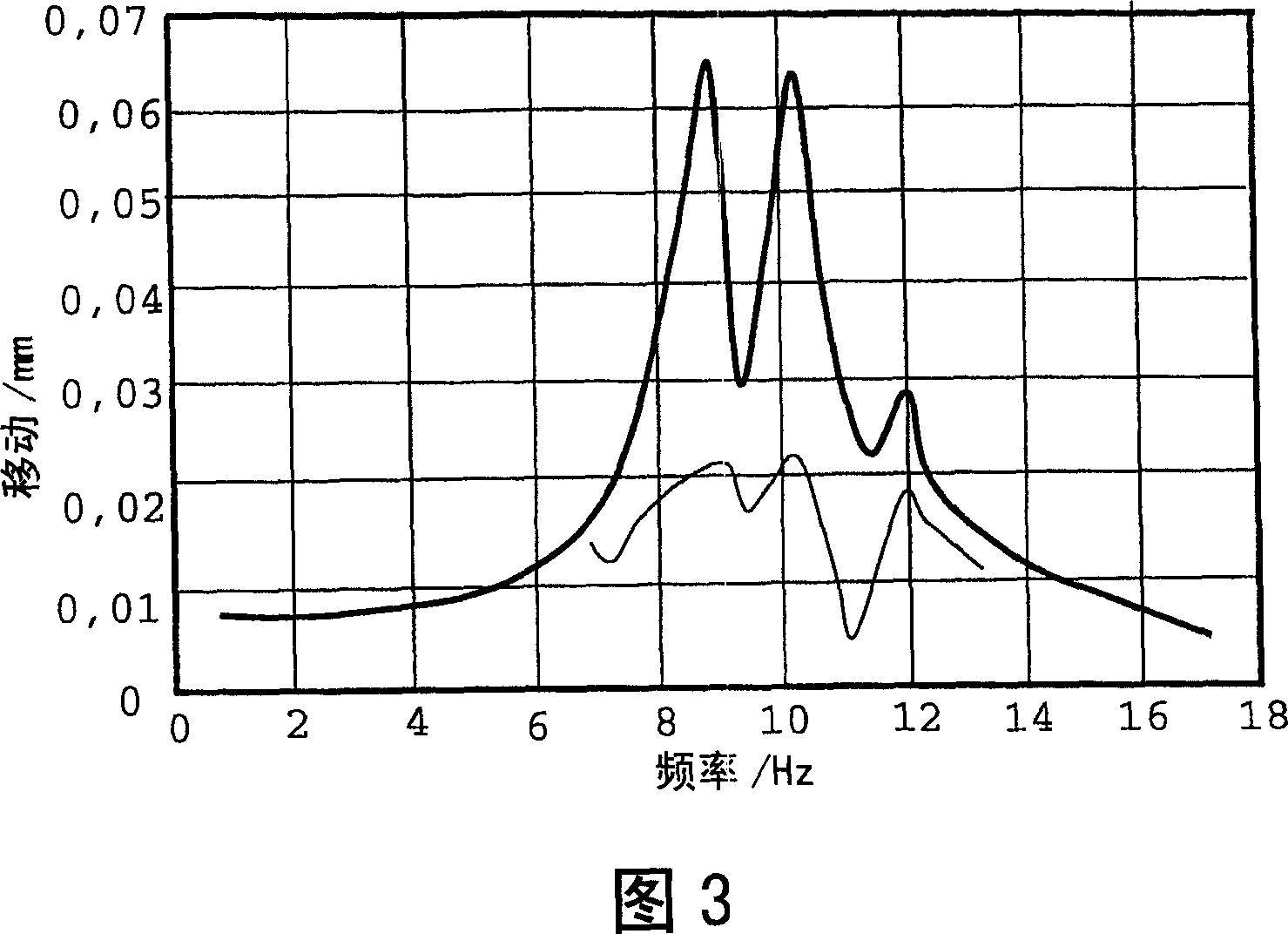

[0025]The invention adopts a vibration damping element that absorbs vibration energy. This damping element is a viscous damping shock absorber related to the speed of the vibration part, and its function can be expressed by the following formula

[0026] mx″+cx′+kx=F(t) formula (1)

[0027] among them:

[0028] m is the quality;

[0029] c is the damping coefficient (standard);

[0030] k is the coefficient of elasticity;

[0031] F(t) is the system load that changes with time;

[0032] x" is acceleration;

[0033] x′ is the speed;

[0034] x is the displacement.

[0035] In the above formula, the viscous damping damper that generates F(t) can be realized through various technical solutions, and the mutual relationship between them can be referred to the following known technology.

[0036] In the hysteretic damping shock absorber, the damping damping force generally depends on the deformation (ie displacement) of the damping and damping material. The function of hysteresis dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com