Radiator

A heat sink and heat dissipation fin technology, which is applied in the fields of instruments, cooling/ventilation/heating transformation, electrical digital data processing, etc., can solve the problem of reducing the number of heat dissipation fins, easily deforming or breaking the fins, and reducing the utilization rate of the fins, etc. problem, to achieve the effect of heat dissipation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The radiator of the present invention is used to dissipate heat from heating electronic components such as a central processing unit and an integrated circuit chip (not shown in the figure).

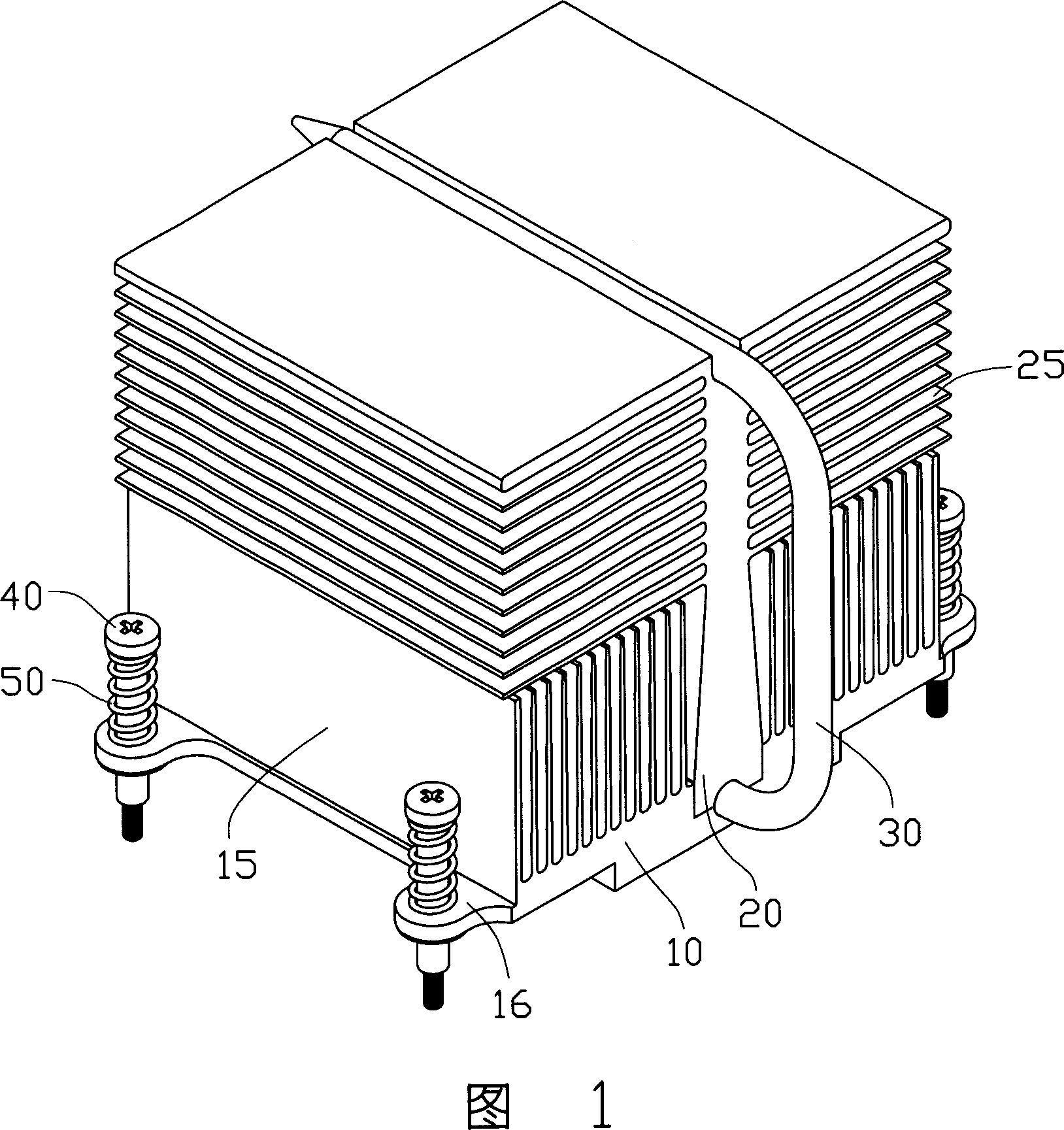

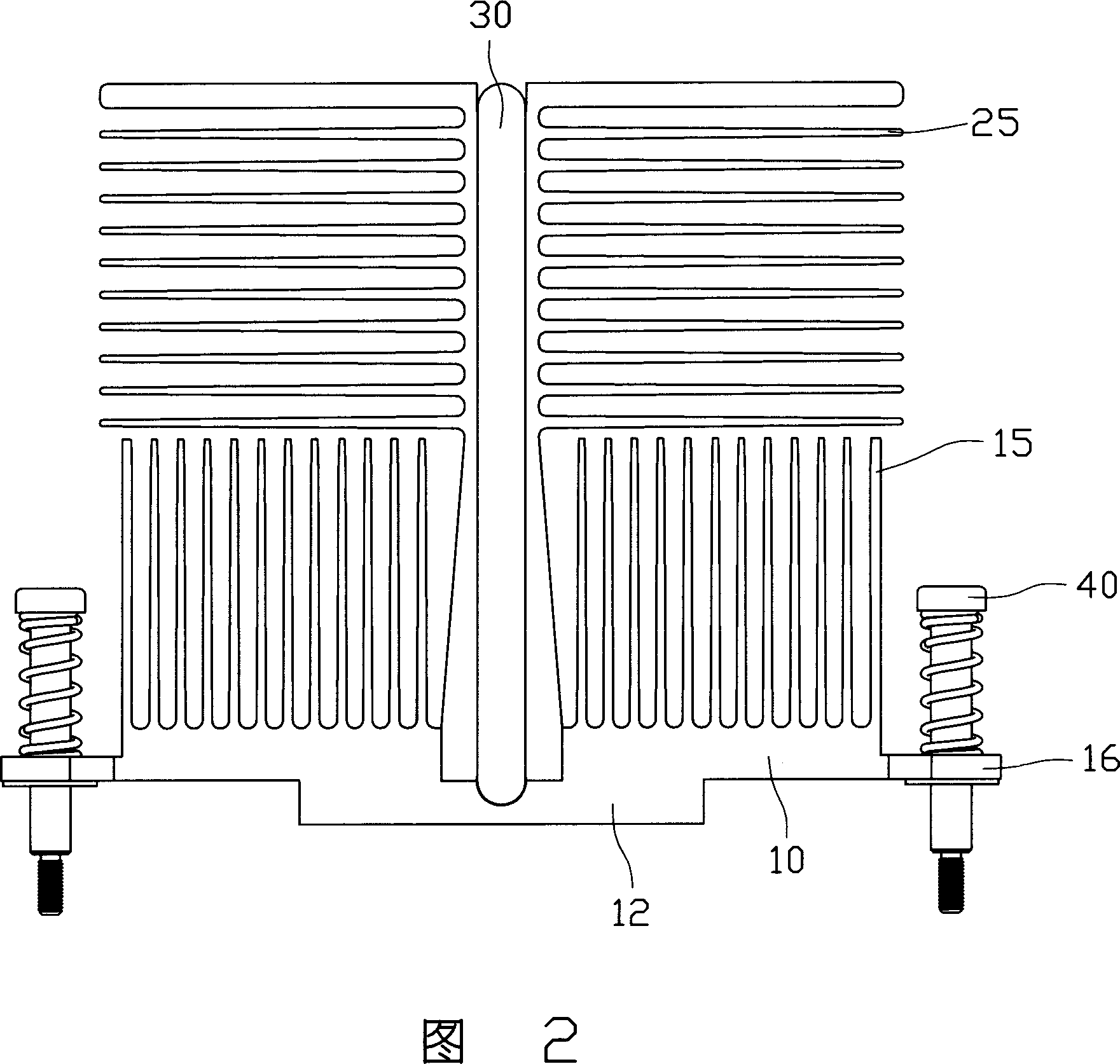

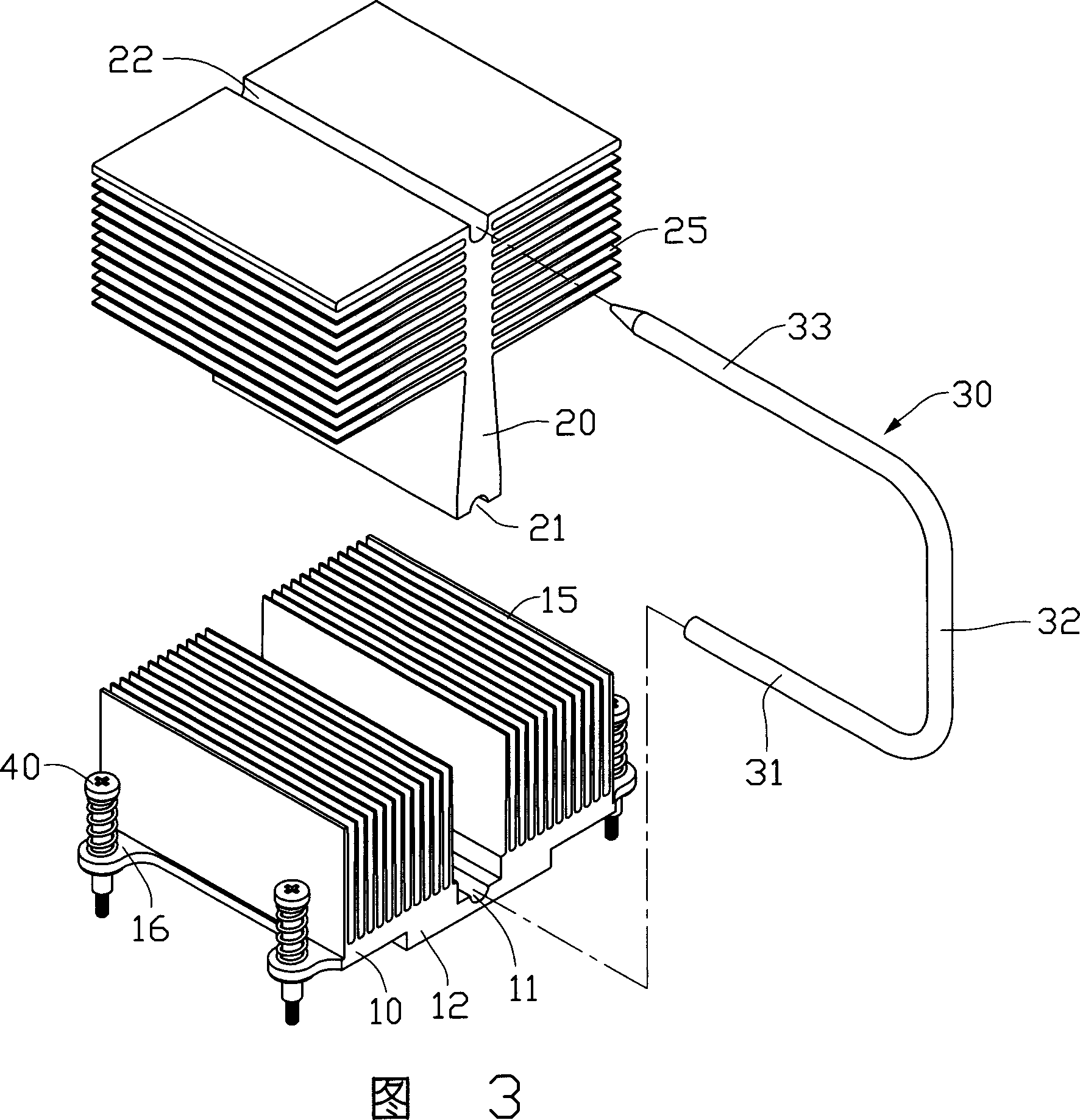

[0014] Please refer to FIG. 1 and FIG. 2 , which are preferred embodiments of the radiator of the present invention. The heat sink includes a base 10 for contacting with electronic components to absorb heat, a plurality of parallel first cooling fins 15 extend from the upper surface of the base 10, and a heat conducting member 20 is vertically fixed on the base 10 Above, a plurality of second cooling fins 25 extend from the heat conducting element 20 , and a C-shaped heat pipe 30 connects the base 10 and the heat conducting element 20 .

[0015] Please refer to Fig. 3, the base 10 is in the shape of a rectangular flat plate, has a bottom surface and a top surface, the bottom surface forms a protrusion 12 for contacting the electronic components to absorb heat, and a groove 11 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com