Straight opening bucket scrubbing device

A technology of brushing mechanism and main frame, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, and program control in sequence/logic controllers, etc. problems, to achieve the effect of reducing labor intensity, improving production efficiency, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

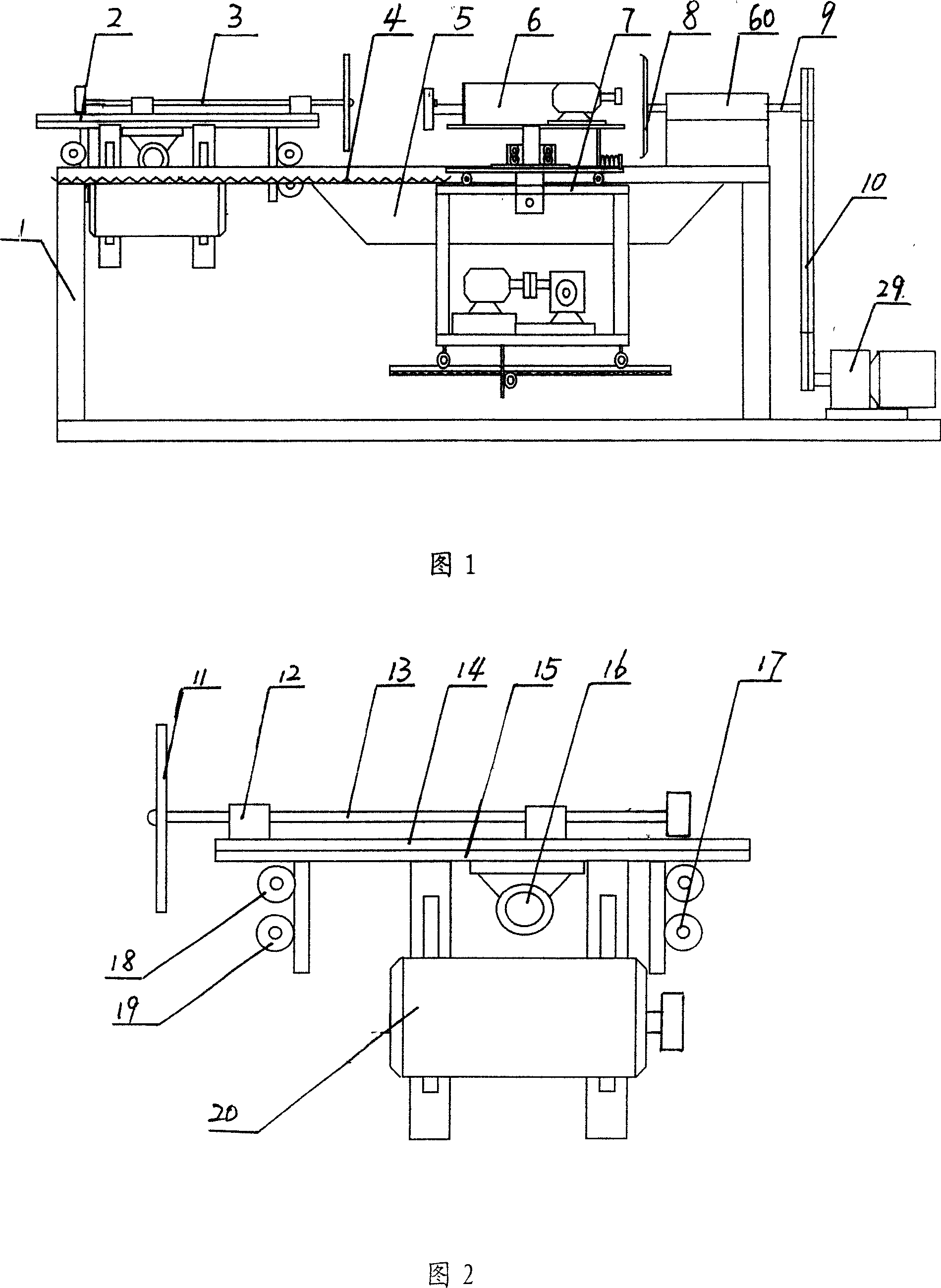

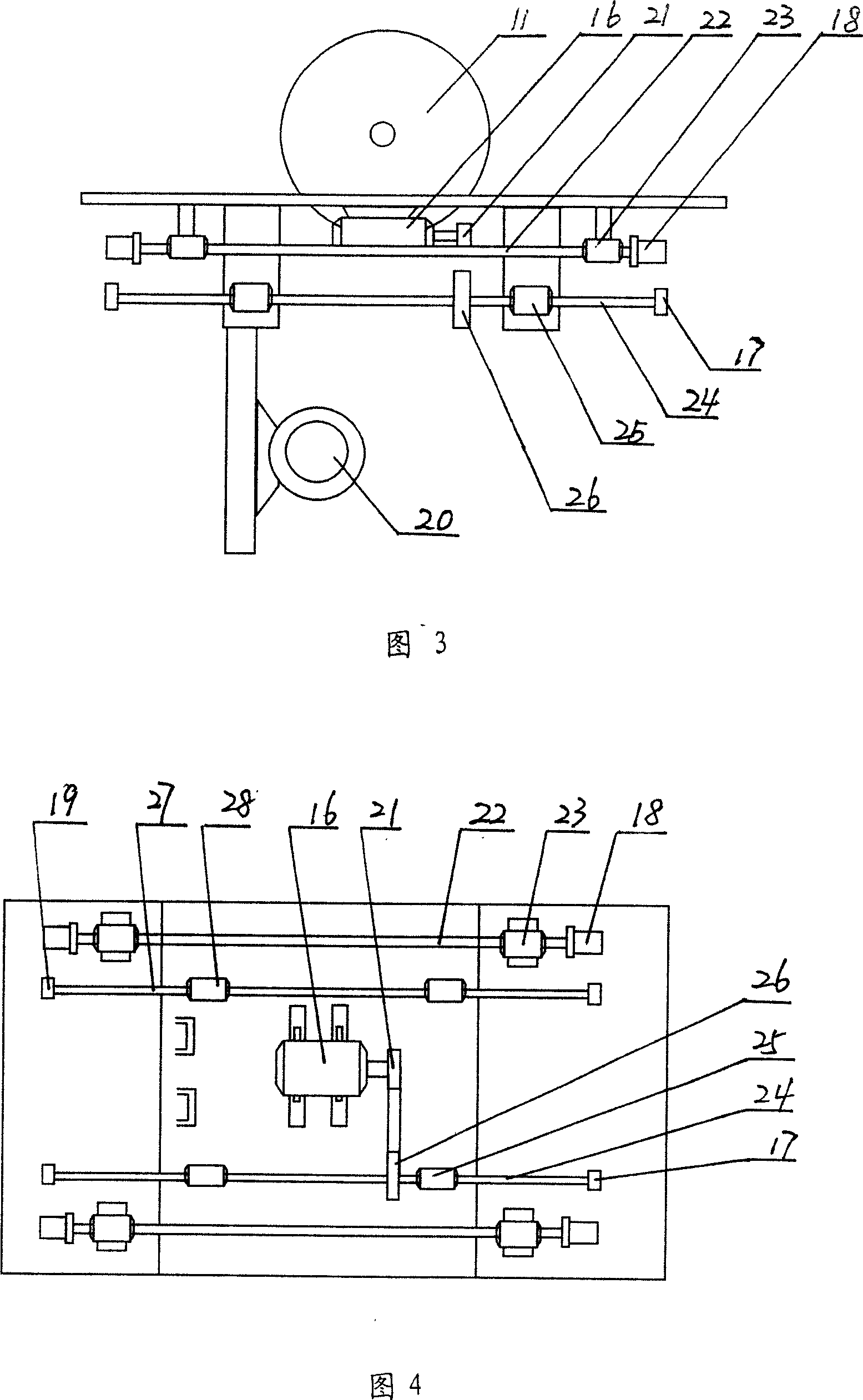

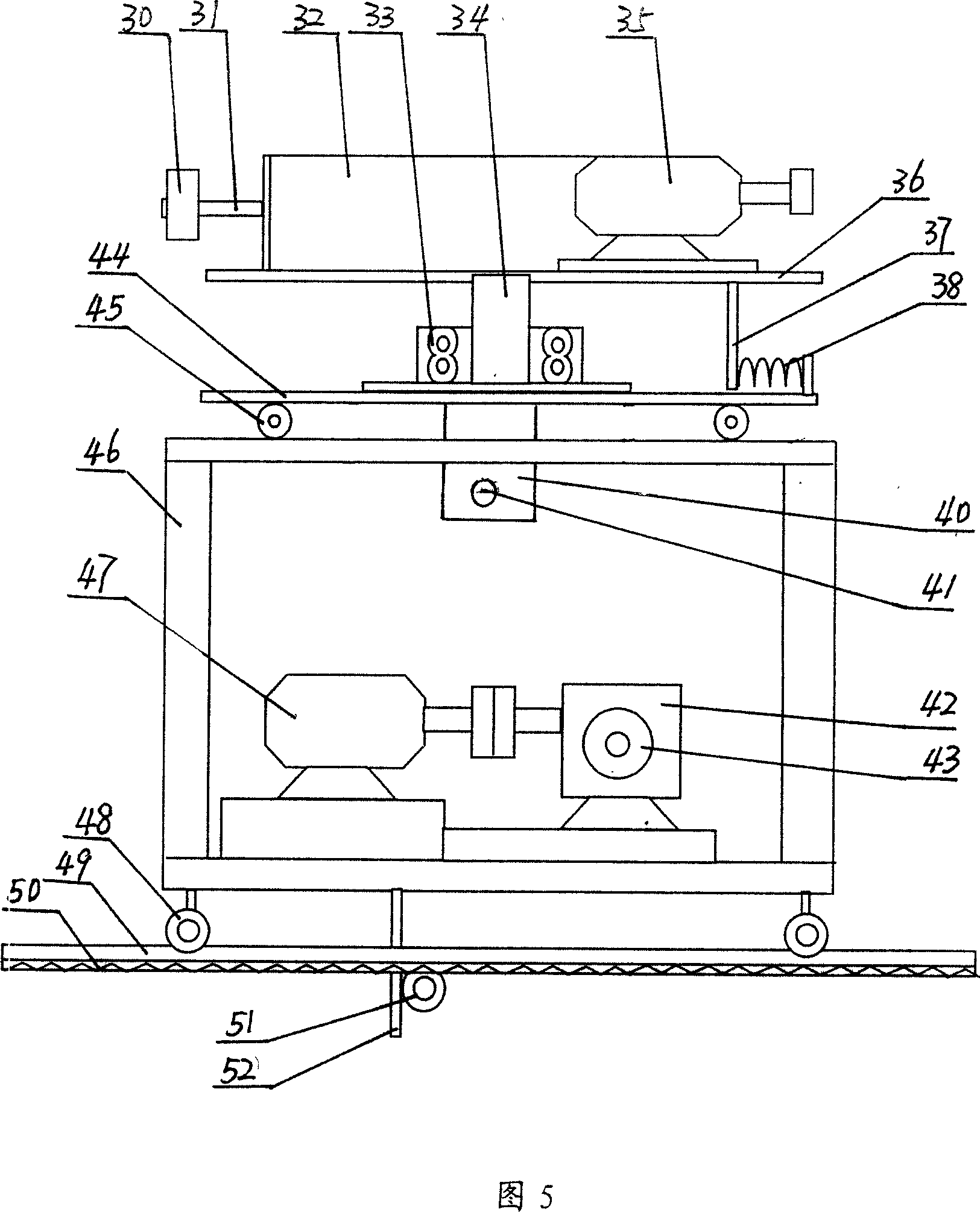

[0026] The structure of the straight opening barrel scrubbing device of the present invention is as shown in Figure 1, comprises main frame 1, inner wall scrubbing trailer 2, inner wall scrubbing mechanism 3 and barrel rotating mechanism, one end of main frame is provided with inner wall scrubbing trailer, and the other end is provided with barrel rotating mechanism. The inner wall scrubbing trailer is provided with an inner wall scrubbing mechanism. The schematic diagrams of the inner wall scrubbing trailer and the inner wall scrubbing mechanism are shown in Figure 2, Figure 3 and Figure 4, the inner wall scrubbing trailer includes a support 15 and an inner wall scrubbing advance and retreat motor 16, the support is provided with a travel shaft 22 by a shaft bracket 23, and the travel shaft The two ends of each are respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com