Porous light concrete and common concrete composite member, method for producing same, and building therefrom

A technology of composite components and composite structures, which is applied in the direction of building structures, buildings, building components, etc., can solve the problems of inability to meet the needs of building energy conservation, poor heat insulation, thermal insulation effects, and large open-air construction operations, and achieve the benefits of civilization Construction, improve thermal insulation performance, reduce the effect of wet work engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

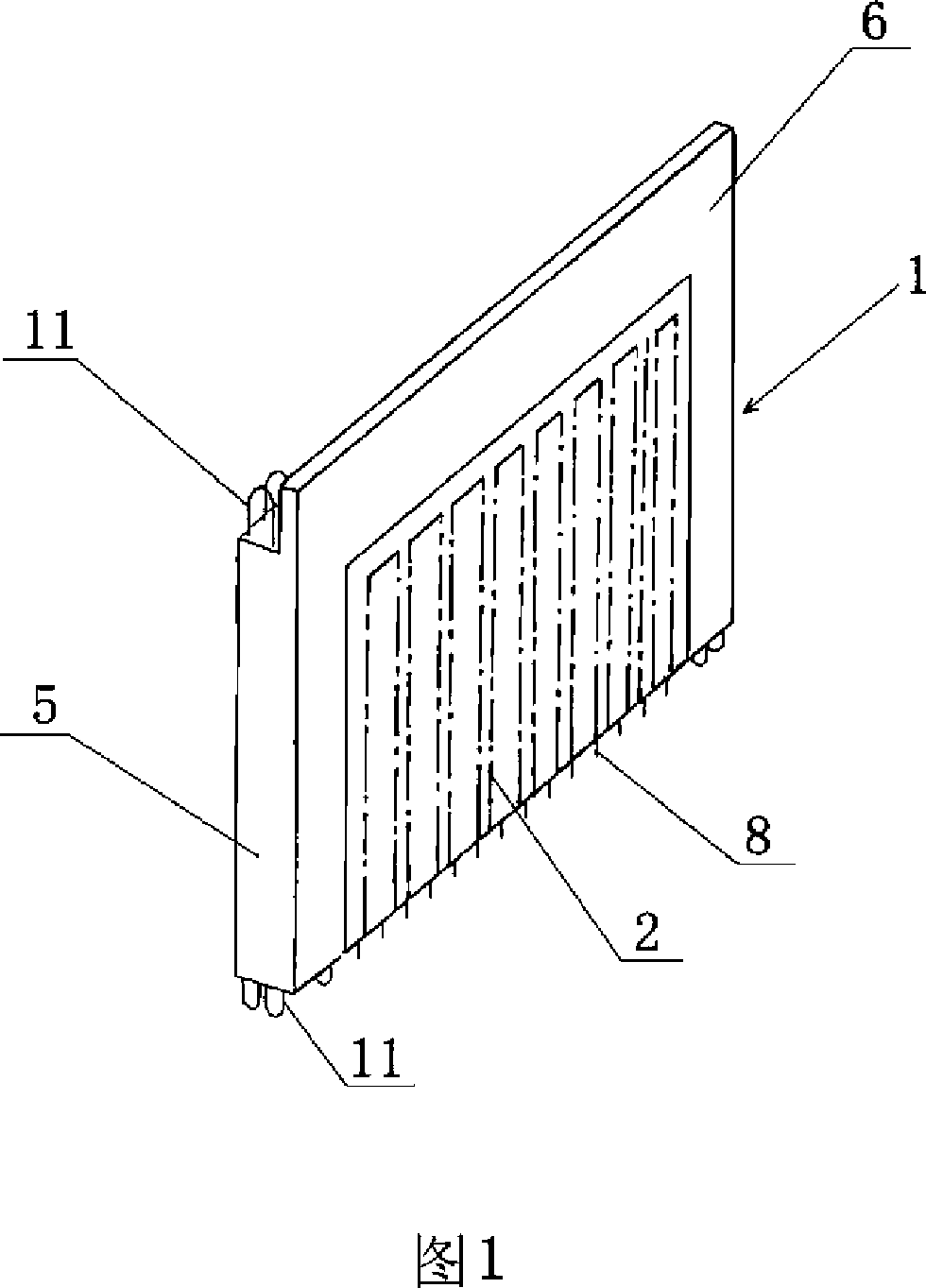

[0056] Embodiment 1 Referring to Fig. 1, a composite member of light-pumped concrete and ordinary concrete is a reinforced concrete two-dimensional plate-shaped member 1 equipped with a steel cage and a steel mesh inside, which is characterized in that: the two-dimensional The load-bearing part of the portal frame and the enclosure and shielding part located in the core of the frame constitute a two-dimensional portal frame light-wall composite structure. The load-bearing part is composed of ordinary reinforced concrete, and the enclosure and shielding part are prefabricated It is composed of a light-weight concrete core board 2 with holes, and the above-mentioned prefabricated light-weight concrete core board 2 with holes is poured into a whole with ordinary reinforced concrete in the load-bearing part of the two-dimensional portal frame;

[0057] The upper part of the two-dimensional portal frame is a semi-finished structural beam 6, and the semi-finished structural beam is o...

Embodiment 2

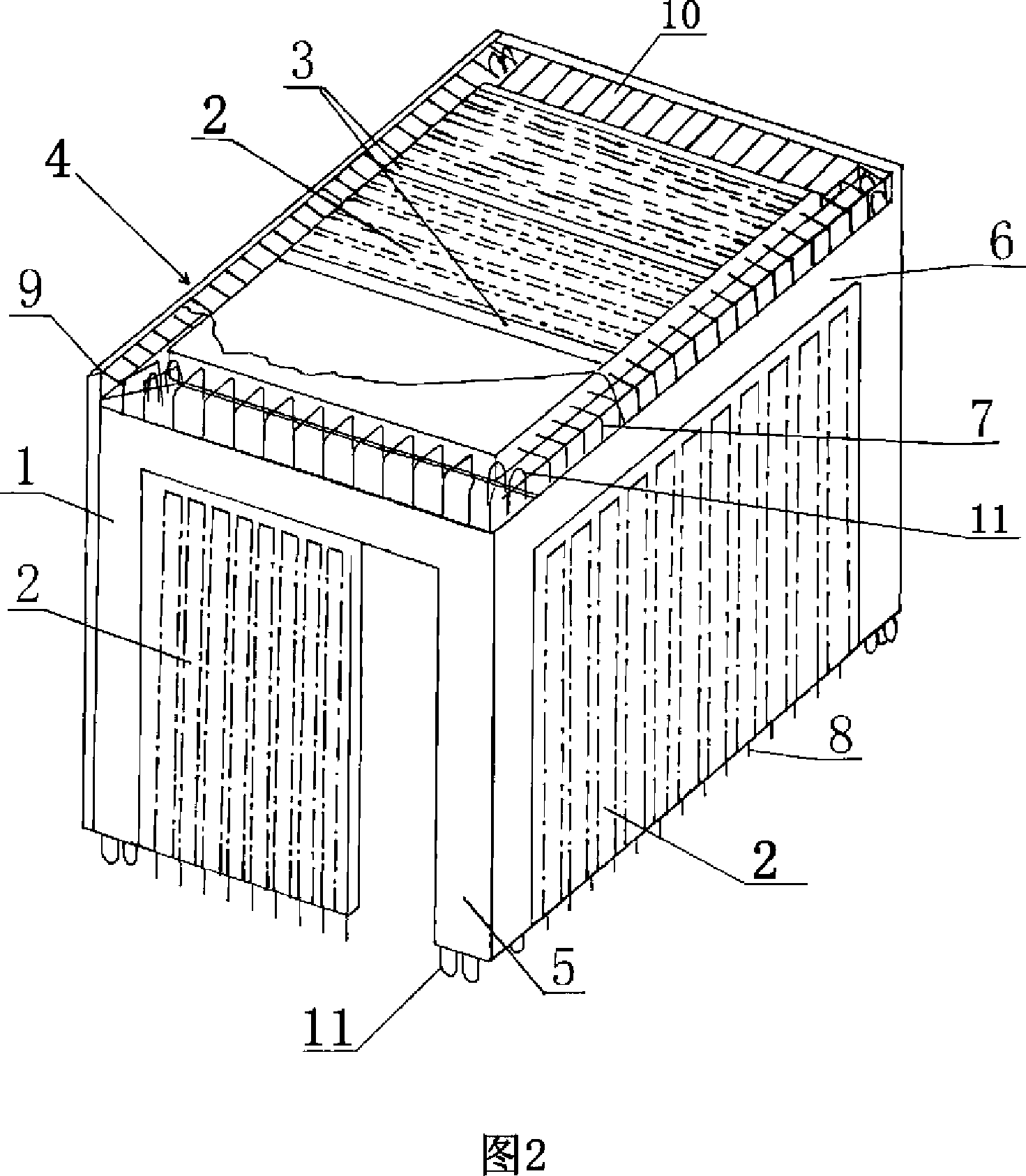

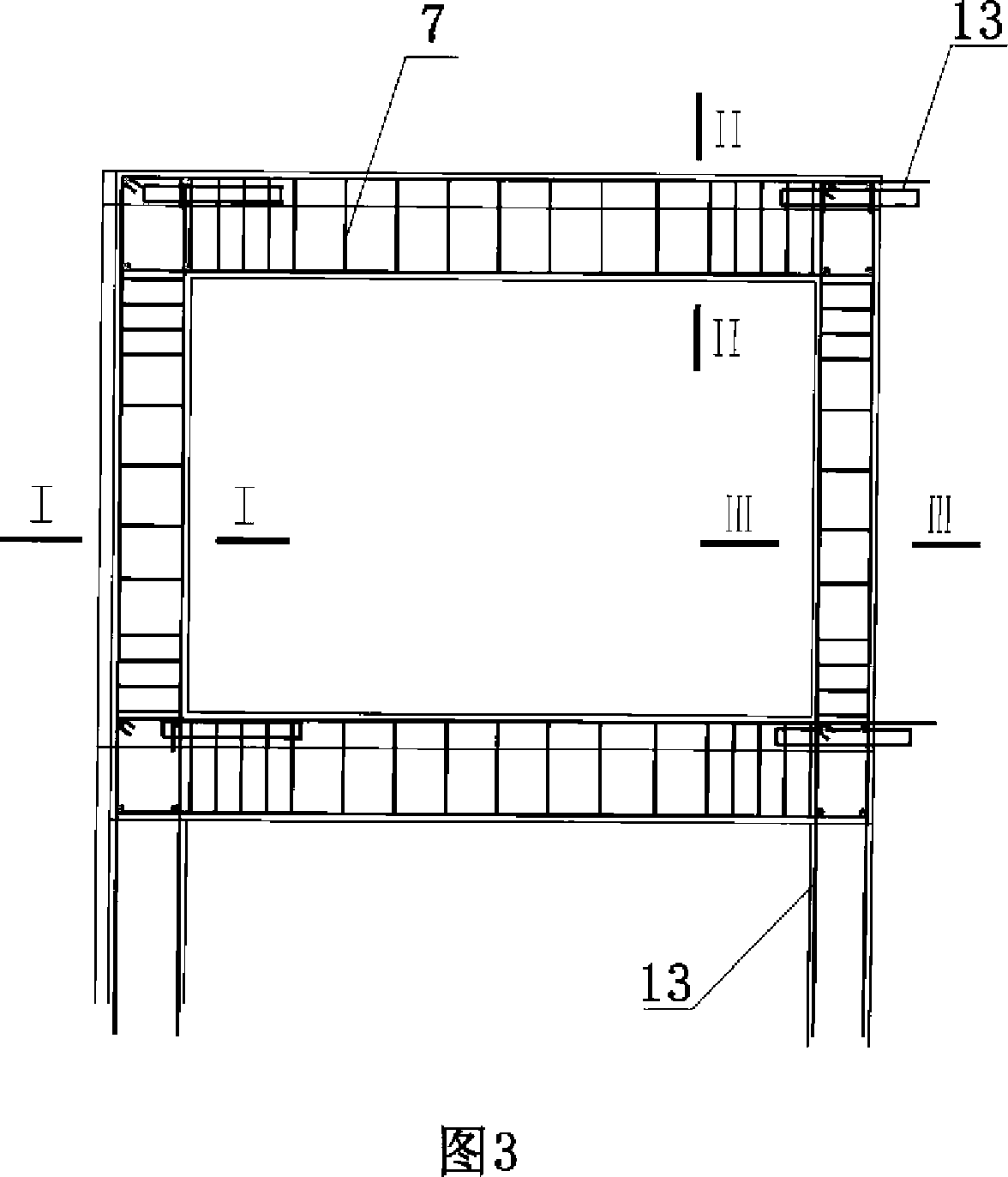

[0060] Embodiment 2 Referring to Fig. 2, another composite member of light-pumped concrete and ordinary concrete is a reinforced concrete box-shaped member 4 equipped with a steel cage and a steel mesh inside, and it is characterized in that: the three-dimensional box-shaped The load-bearing part of the frame and the enclosure and shielding part located in the core of the frame constitute a three-dimensional box-shaped frame light-wall composite structure. Concrete core slab, the above-mentioned prefabricated light-weight concrete core slab and the ordinary reinforced concrete in the load-bearing part of the three-dimensional box-shaped frame are poured into a whole.

[0061] Rib beams 3 are distributed on the upper floor of the above-mentioned three-dimensional box-shaped frame, and prefabricated light-weight concrete core panels with holes are located between the rib beams 3 .

[0062] The upper part of the above-mentioned three-dimensional box-shaped frame is a semi-finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density grade | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com