Static discharge protection structure, element and manufacturing of element

A technology for electrostatic discharge protection and electrostatic discharge, which is applied in the direction of static indicators, instrument parts, shielding, etc., and can solve problems such as damage, lack of components on the display, and inability to effectively release energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

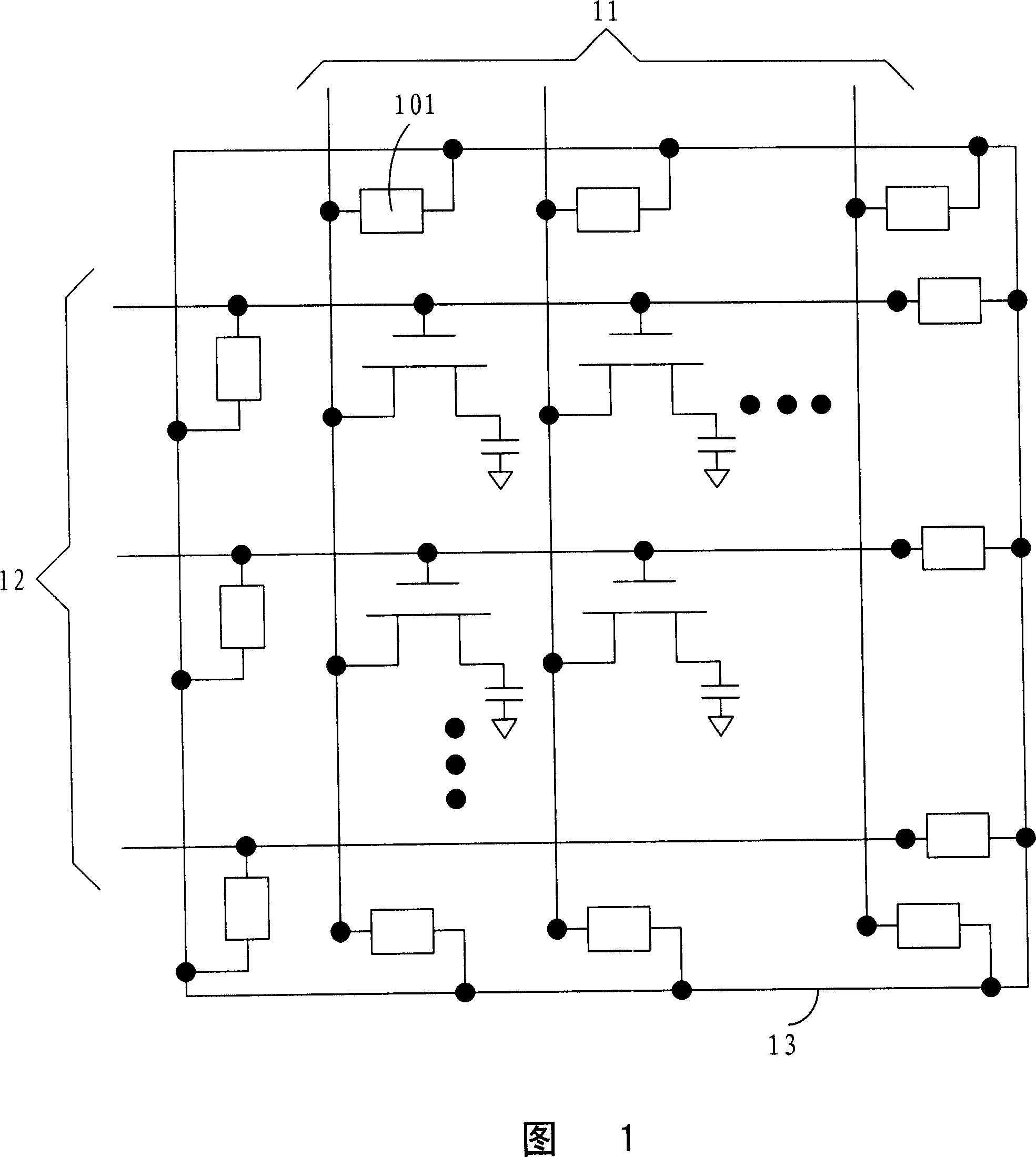

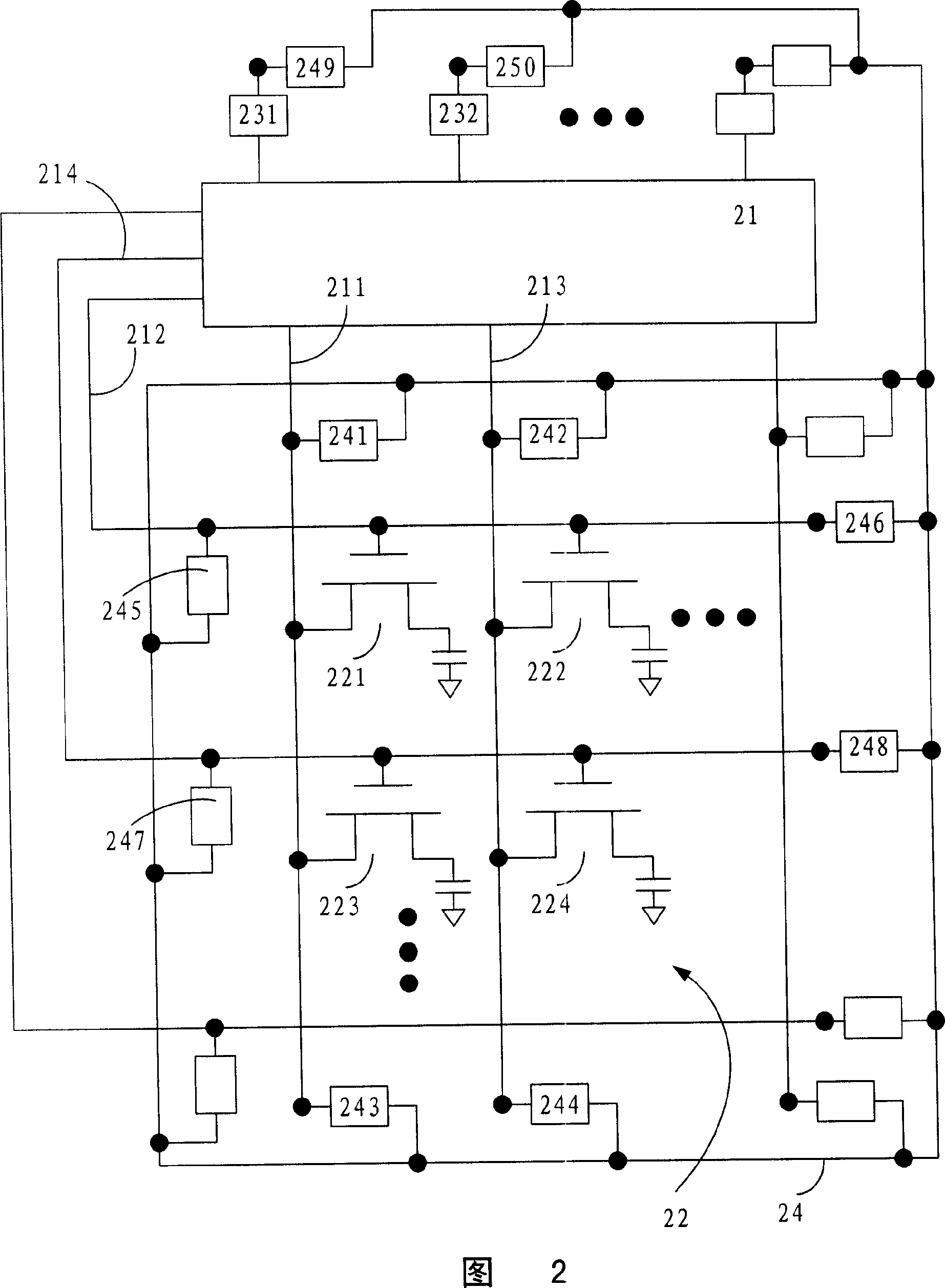

[0019] FIG. 2 shows a first embodiment of the present invention, which provides an electrostatic discharge protection structure between the integrated driving circuit 21 and the pixel array 22 . The output terminal of the driving circuit is respectively connected to the gate and source / drain of each thin film transistor in the pixel array 22 . In FIG. 2 , only a schematic diagram of connection between a part of the pixel array 22 and the driving circuit 21 is shown. The data lines 211 are connected to the pixel array, and are arranged as source / drain electrodes of a plurality of thin film transistors in a row. In FIG. 2 , only a part of the thin film transistors 221 and the thin film transistors 223 connected to the data lines 211 are shown. Similarly, the sources / drains of the TFTs 222 and 224 are connected to the data line 213 . Gates of the thin film transistor 221 and the thin film transistor 222 are connected to the gate line 212 . Gates of the thin film transistor 223 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap