A TFT LCD pixel structure

A pixel structure and pixel electrode technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing device aperture ratio, TFT pixel electrode damage, high pressure, etc., to increase the aspect ratio and increase the on-state current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

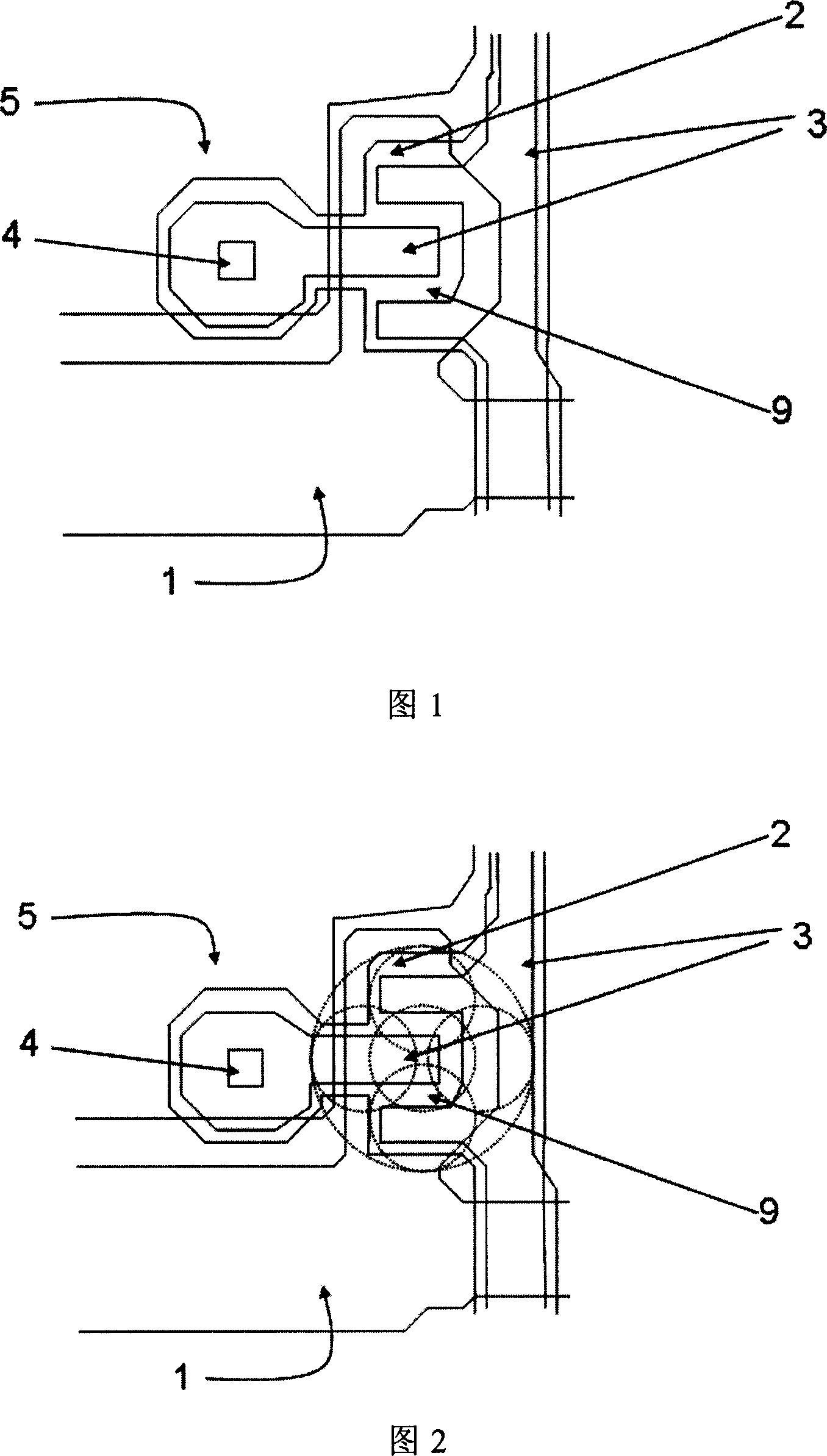

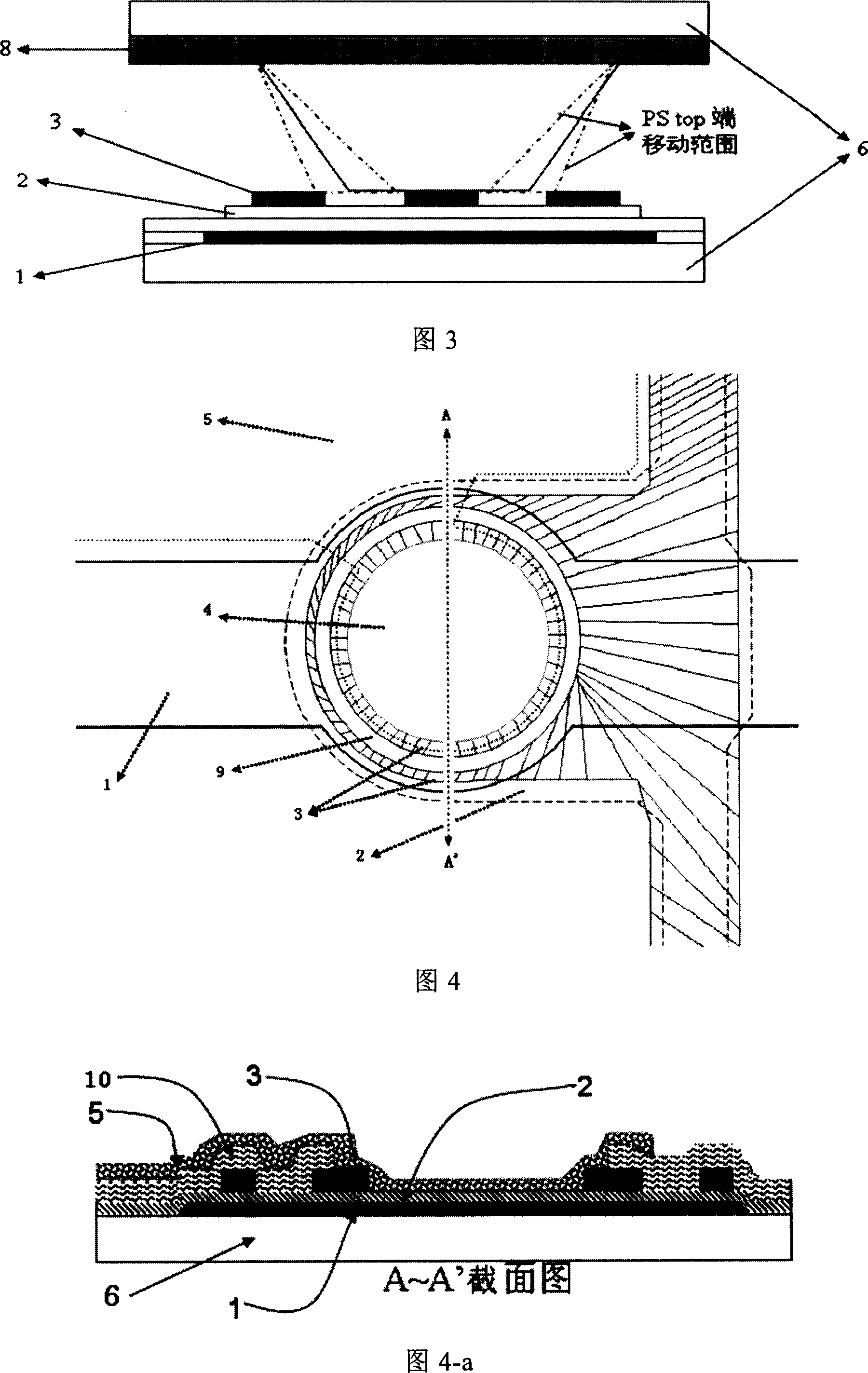

[0025] As shown in Figure 4 and Figure 4A. First, gate leads are formed on the glass substrate 6, wherein the gate electrode 1 and the gate leads are integrated, the gate electrode 1 is circular, and the active layer 2 with a circular structure is formed on the gate electrode 1 by photolithography and other processes. A double circular source-drain electrode 3 is formed on the active layer 2, a circular conductive channel 9 is formed between the source-drain electrodes 3; a passivation layer 10 is formed above the source-drain electrode 3 and the conductive channel 9 On the passivation layer 10, a circular via hole 4 is formed in the source contact, and the pixel electrode 5 is connected to the source terminal of the source-drain electrode 3 through the circular via hole 4. After the final pixel electrode 5 process is completed, a The middle part is a planar device structure.

[0026] Through the design of the circular TFT structure in Figure 4 and Figure 4A, the width-to-len...

Embodiment 2

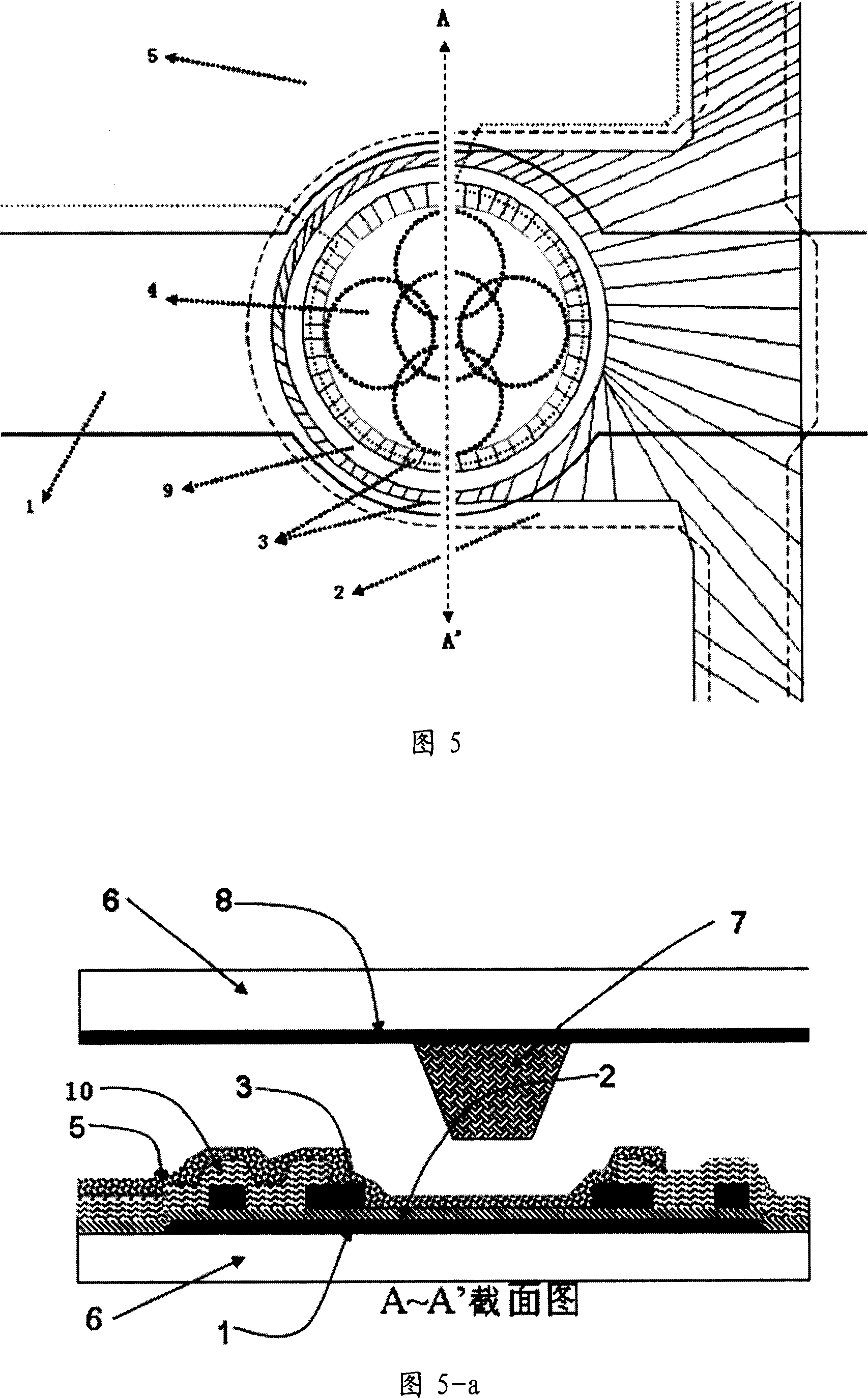

[0031] As shown in Figure 6 and Figure 6A. In consideration of reducing the parasitic capacitance, a hollow structure can be formed on the bottom gate electrode 1 of the TFT device structure described in Embodiment 1, so as to reduce the parasitic capacitance between the gate and the source, and at the same time increase the depth of the annular valley and strengthen the Restriction on the movement of the columnar spacer 7. Wherein, the shape of the hollow structure is preferably circular, and may also be polygonal, and fits with the upper end of the columnar spacer 7 .

Embodiment 3

[0033] As shown in Figure 7 and Figure 7A. In order to avoid disconnection of the pixel electrode 5 due to the step effect formed by the source-drain electrode 3 and the passivation layer 10 at the connection part between the pixel electrode 5 and the via hole 4, it can be used in the TFT device described in Embodiment 1 or Embodiment 2 , on the basis of sacrificing the width-to-length ratio of the part, the source and drain electrodes 3 are circularly opened to form a flat contact surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com