Encapsulation structure of optical sensor

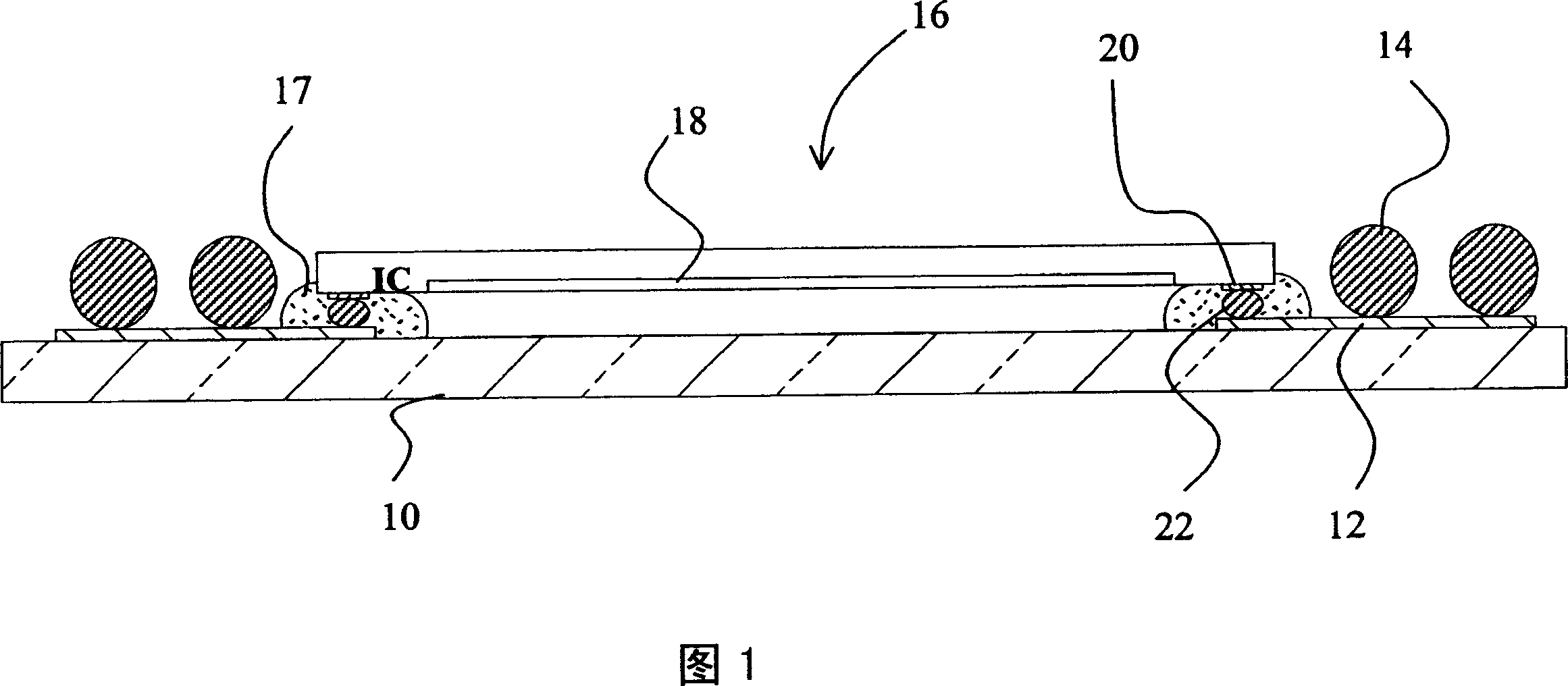

A packaging structure and light sensor technology, which is applied to electric solid devices, semiconductor devices, radiation control devices, etc., can solve the problem of colloid layer contaminating metal balls and light sensing areas, avoid contamination of light sensing areas, and reduce packaging. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

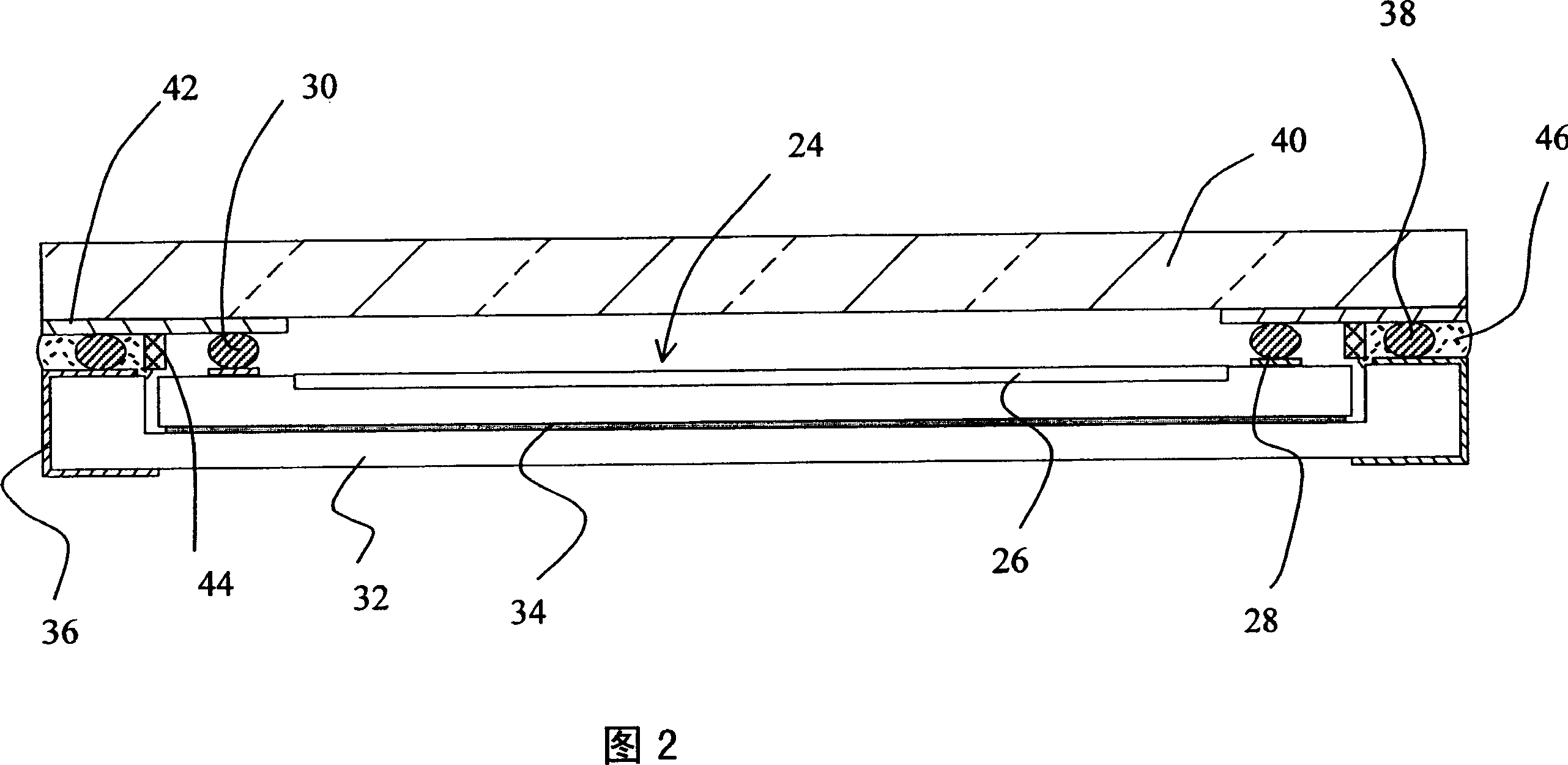

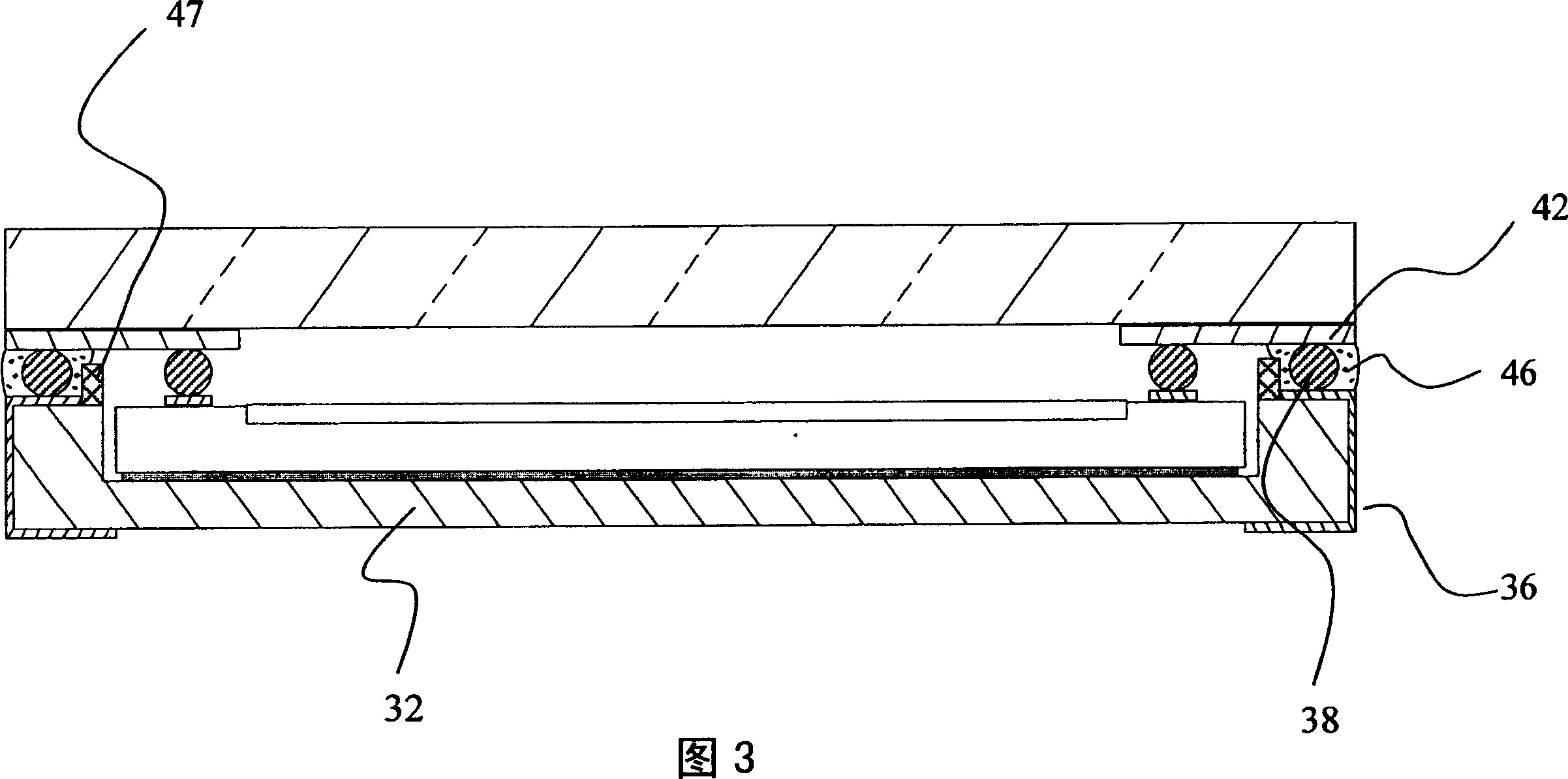

[0033] The present invention relates to a light sensor packaging structure. Please refer to FIG. 2, which is a schematic diagram of an embodiment of the present invention. The present invention mainly includes a light sensing component 24, which includes a light sensing area 26 and a plurality of welding pads 28. There are a plurality of metal connection points 30 on the welding pad 28; a substrate 32, which has an adhesive layer 34 for bonding the light sensing component 24 on the substrate 32, and the edge side of the substrate 32 is provided with metal wiring 36 and A plurality of metal connection points 38 located on the metal wiring 36, a light-transmitting layer 40 covering the light-sensing component 24 and the substrate 32, which can be a light-transmitting glass that can filter a certain wavelength, the light-transmitting layer 40 is provided with metal wiring 42, and metal connection point 30, metal wiring 42, metal connection point 38 form electrical connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com