Pressure stabilizing filter tube with double air cushion layer and independent water distribution and gas distribution

A filter tube and water distribution technology, which is used in filtration and separation, gravity filter, loose filter material filter, etc., can solve the problem of unable to replace filter bricks, filter head reconstruction, etc., to improve water supply water quality and production efficiency, backwash The effect of reducing energy consumption and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

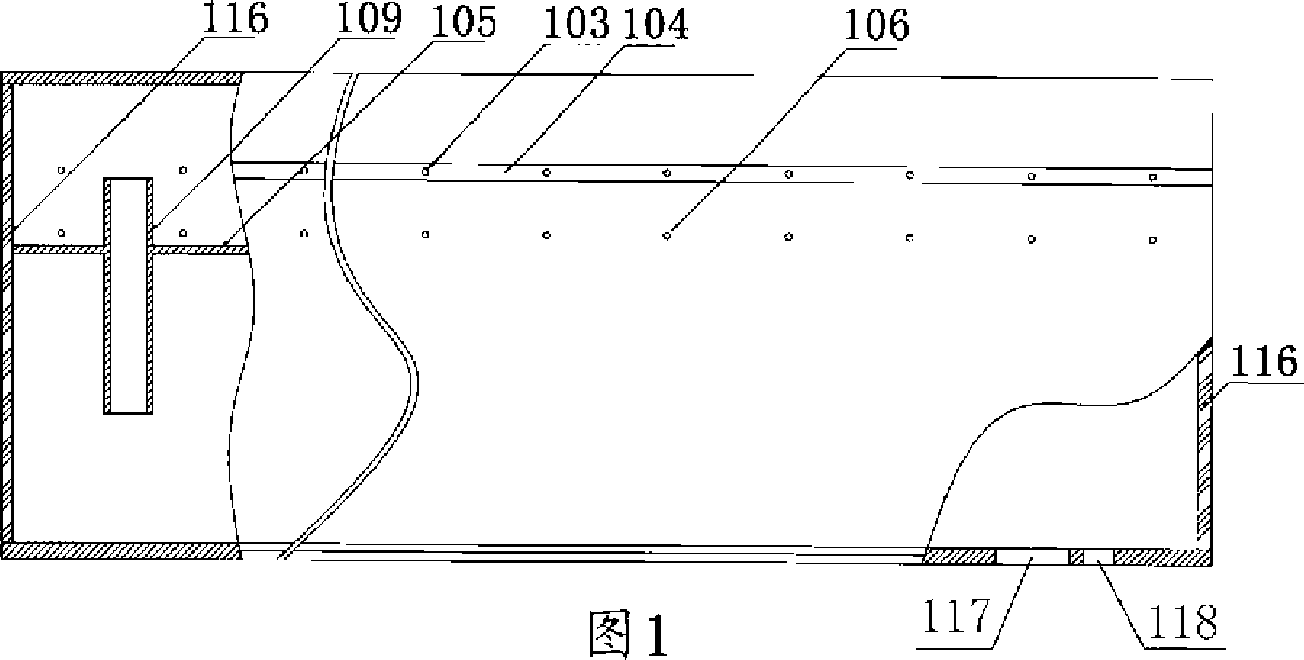

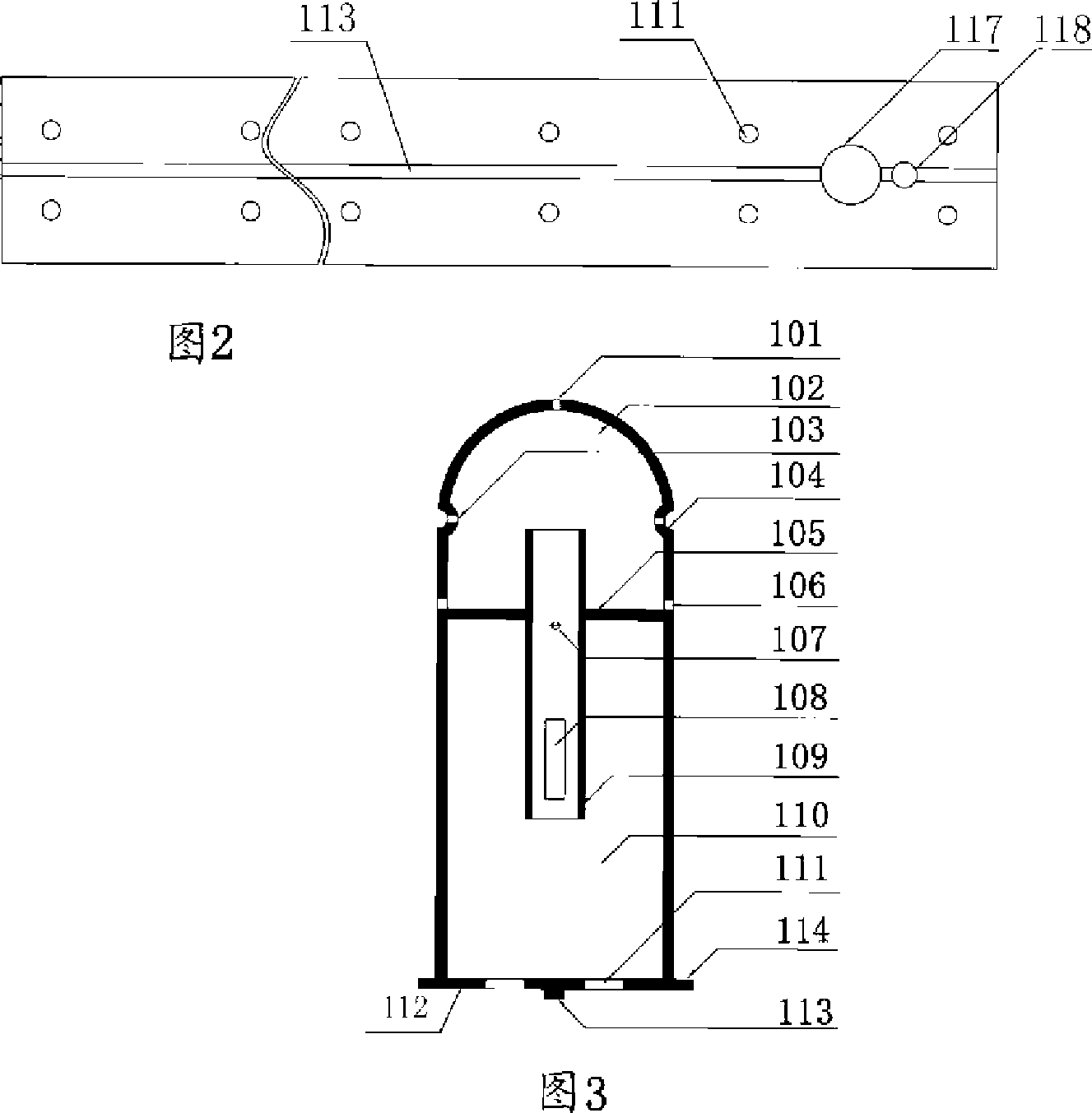

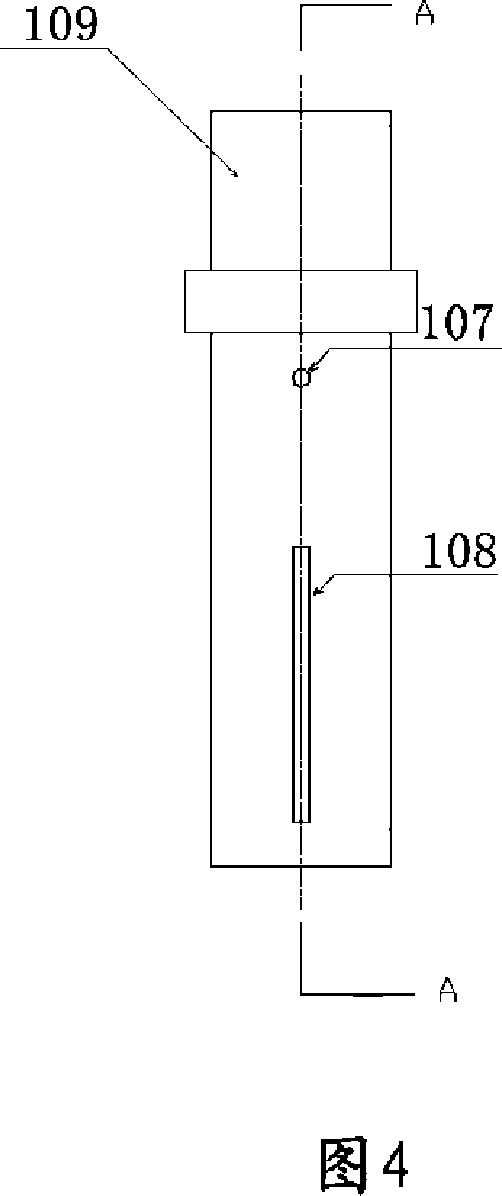

[0057] Filter embodiment 1 Referring to Fig. 9 , it is a filter using the above-mentioned independent water distribution and gas distribution and having a double air cushion pressure-stabilizing filter tube 1, and the filter tube 1 is arranged horizontally in the filter tank. There is a downward concave pipe ditch 10 on the filter tank bottom plate 5, and a water main pipe 9 and a recoil air main pipe 8 are built in the pipe ditch. The first embodiment of the connection between the filter tube and the water and gas pipelines: the above-mentioned water connection pipe interface hole and the gas connection pipe interface hole are arranged on the bottom plate of the filter tube, and the water connection pipe interface hole passes through the water connection pipe 6 and the water main pipe in the pipe ditch. 9 is connected from the bottom of the filter tank, and the gas connection pipe interface hole is connected with the recoil gas main pipe 8 in the pipe ditch through the gas con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com