A floating biological filter backwashing device

A biological filtration and backwashing technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of increased water head loss, affecting the treatment effect of the sewage treatment system, and reducing the voids of fillers, etc. problem, achieve the effect of reducing equipment investment, reducing energy consumption, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

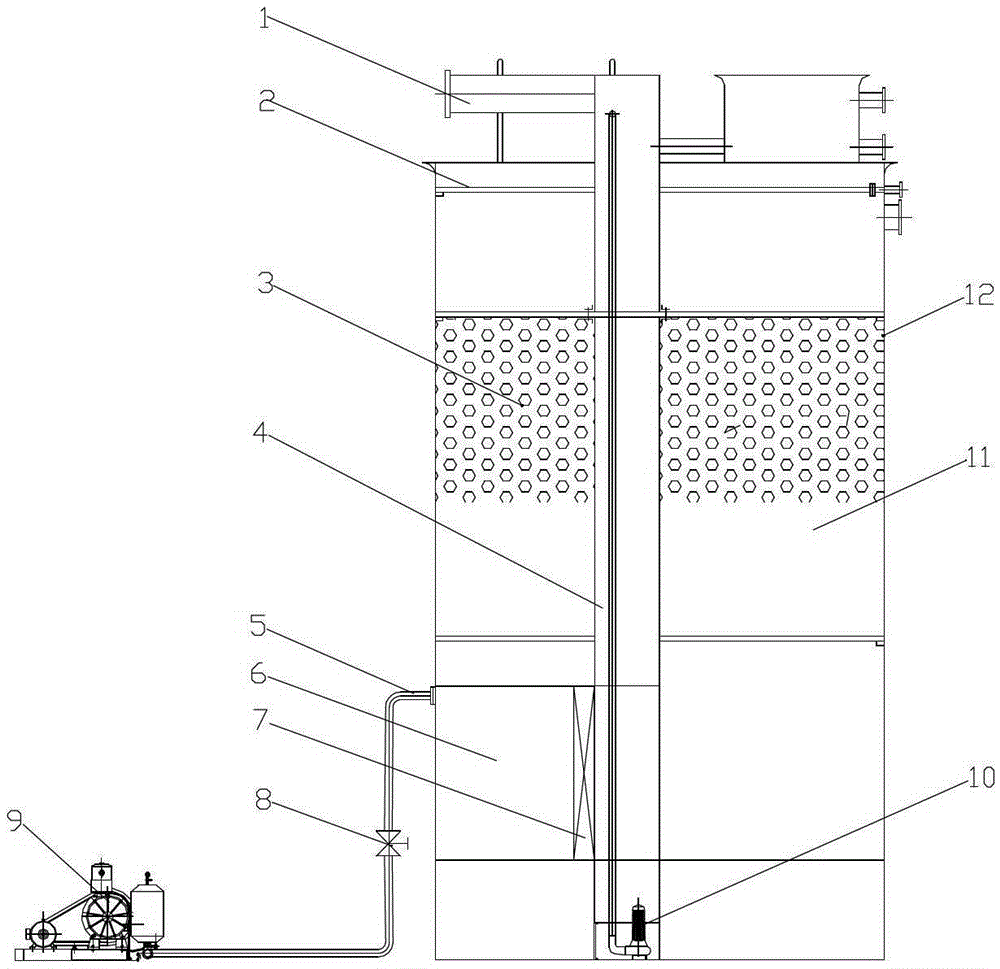

[0017] A floating biological filtration and backwashing device, comprising a pool body 12, a treatment tank 11, the treatment tank 11 is filled with granular floating filler 3 to form a filter layer, and also includes a backwash outlet pipe 1, a backwash sprinkling pipe 2, a backwash Sludge discharge pipe 4, backwash intake pipe 5, air chamber 6, air release mechanism 7, backwash air source 9 and sludge lift pump 10, the air chamber 6 is arranged at the bottom of the pool body 12, and the backwash air source 9 passes through The backwash inlet pipe 5 is connected to the air chamber 6, the air release mechanism 7 is arranged inside the air chamber 6, the outlet of the backwash outlet pipe 1, and the backwash sprinkler pipe 2 are sequentially arranged above the treatment tank 11 from top to bottom, and the sludge is lifted The pump 10 is arranged at the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com