A modular filter water distribution device and its system and application method

A water distribution and gas distribution system technology, applied in chemical instruments and methods, water distribution pipes, separation methods, etc., can solve the problems of uniformity of gas distribution and energy consumption of backwashing, etc., to achieve uniform distribution of gas and water, Reduced voids and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

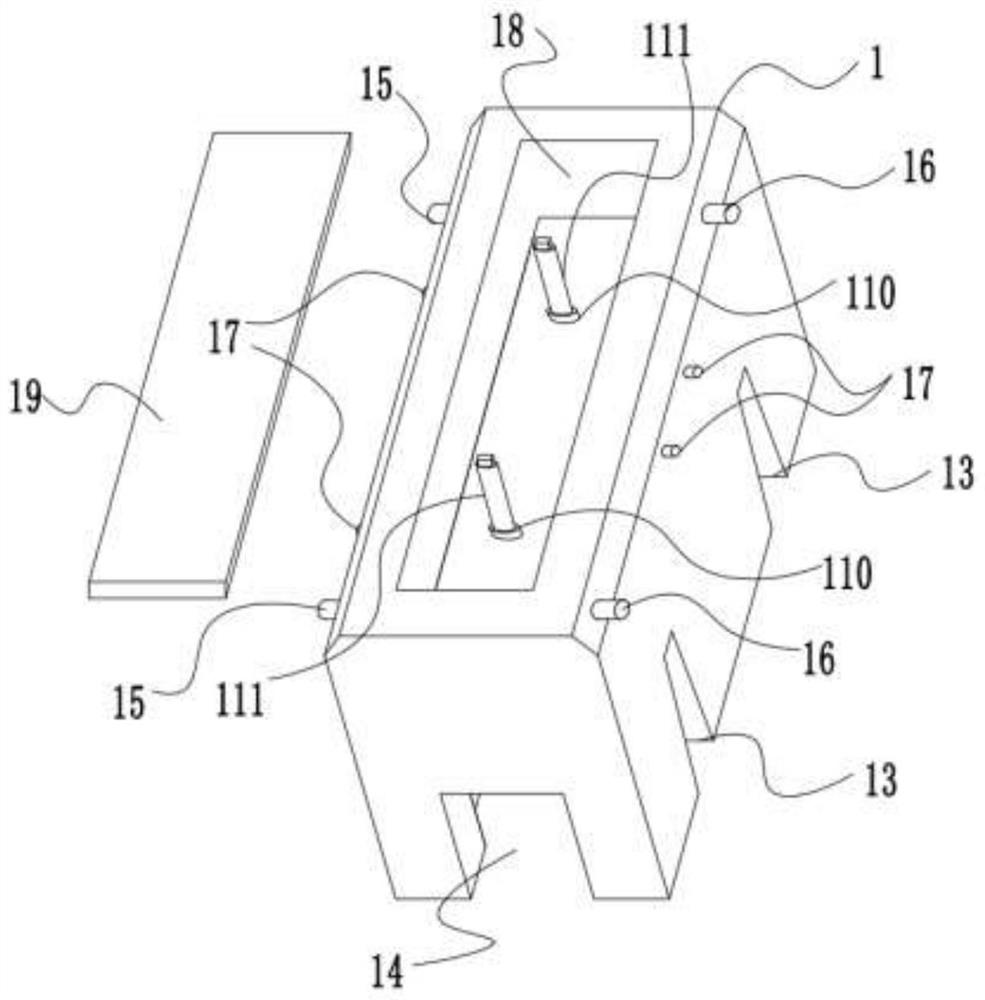

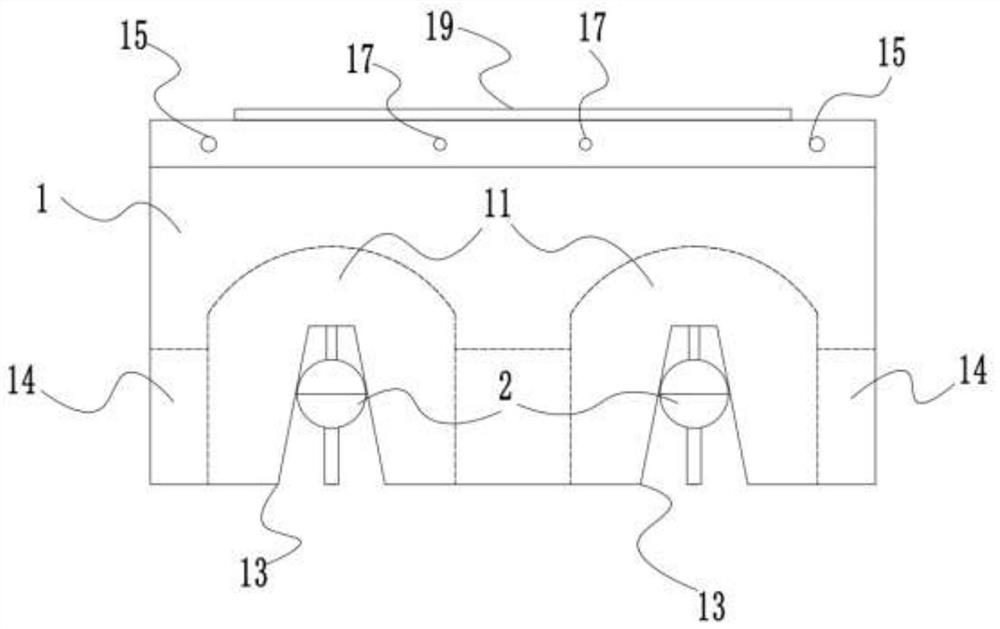

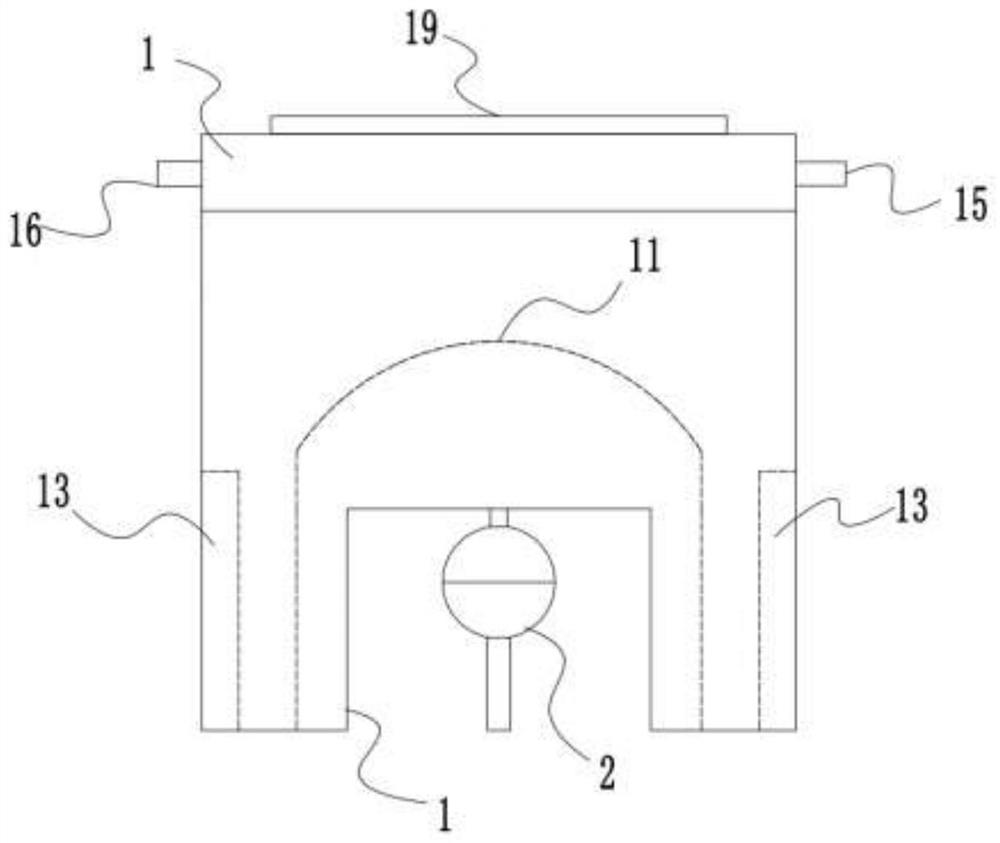

[0050] This embodiment provides a modular filter water and air distribution device, such as figure 2 and 3 As shown, it includes the filter brick body 1 and the water and air distribution assembly 2. The filter brick body 1 is a cuboid structure with a length of 400mm, a width of 200mm, and a height of 200mm. The schematic diagram of the appearance of the filter brick body 1 is as follows figure 1 As shown, the shell of the filter brick body 1 is made of HDPE, and the inside is filled with concrete, so the overall strength is high, and it is durable and not easily damaged. Such as figure 2 As shown, the inside of the filter brick body 1 is provided with two cavities 11 symmetrically distributed about the center line of the filter brick body 1 in the length direction; A flow control gap 13 is opened to make the cavity 11 communicate with the outside; the bottom of the filter brick body 1 is provided with a water flow channel 14, and the water flow channel 14 runs through th...

Embodiment 2

[0060] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 4 and 5 As shown, the inner wall of the cavity 11 is provided with a permanent magnet material layer 12, and the permanent magnet material layer 12 is a plurality of rubidium magnet sheets 121, and the middle part of the rubidium magnet sheet 121 is provided with a fixing hole 122, which is used to wear the rubidium magnet sheet 121 On the bolt 123 on the inner side wall of the cavity 11 and fix it with a nut 124, at the same time, use glue to reinforce between the rubidium magnet sheet 121 and the inner side wall of the cavity 11. The glue can be plastic sticky magnet glue YH-896. Using the rubidium magnet sheet 121 with strong magnetism to form a magnetic field in the area of the cavity 11 can magnetize and disturb the fine water flow ejected from the backwash to form high-oxygen water, which can greatly improve the backwash efficiency.

[0061] Apply the water and gas distribution...

Embodiment 3

[0067] This embodiment is basically the same as Embodiment 2, the difference is: as Figure 8 As shown, the bottom of the water distribution rod 28 is provided with an oxygen-enriched filter screen 213. Further, the oxygen-enriched filter screen 213 is woven by steel fibers and oxygen-enriched anion fibers according to a three-dimensional weaving method, wherein the steel fibers root The quantity ratio of the number and the number of oxygen-enriched anion fibers is 1:3, and the aperture diameter of the oxygen-enriched filter screen 213 is 1.2mm. The steel fiber provides skeleton support, and the oxygen-enriched negative ion fiber can carry out preliminary oxygen-enrichment treatment on the backwash water, which can not only intercept debris to prevent the water distribution hole 27 from clogging, but also increase the oxygen content of the backwash to improve the backwash efficiency. A small pore size is not conducive to the interception of debris, and a too small pore size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com