Hypoeutectic no-lead SnZn alloy brazing alloy

A technology of hypoeutectic tin-zinc and lead-free solder, which is applied in metal processing equipment, welding/cutting medium/material, welding medium, etc., can solve problems such as ignoring the research of Sn-6.5Zn alloy, and achieve practicality, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

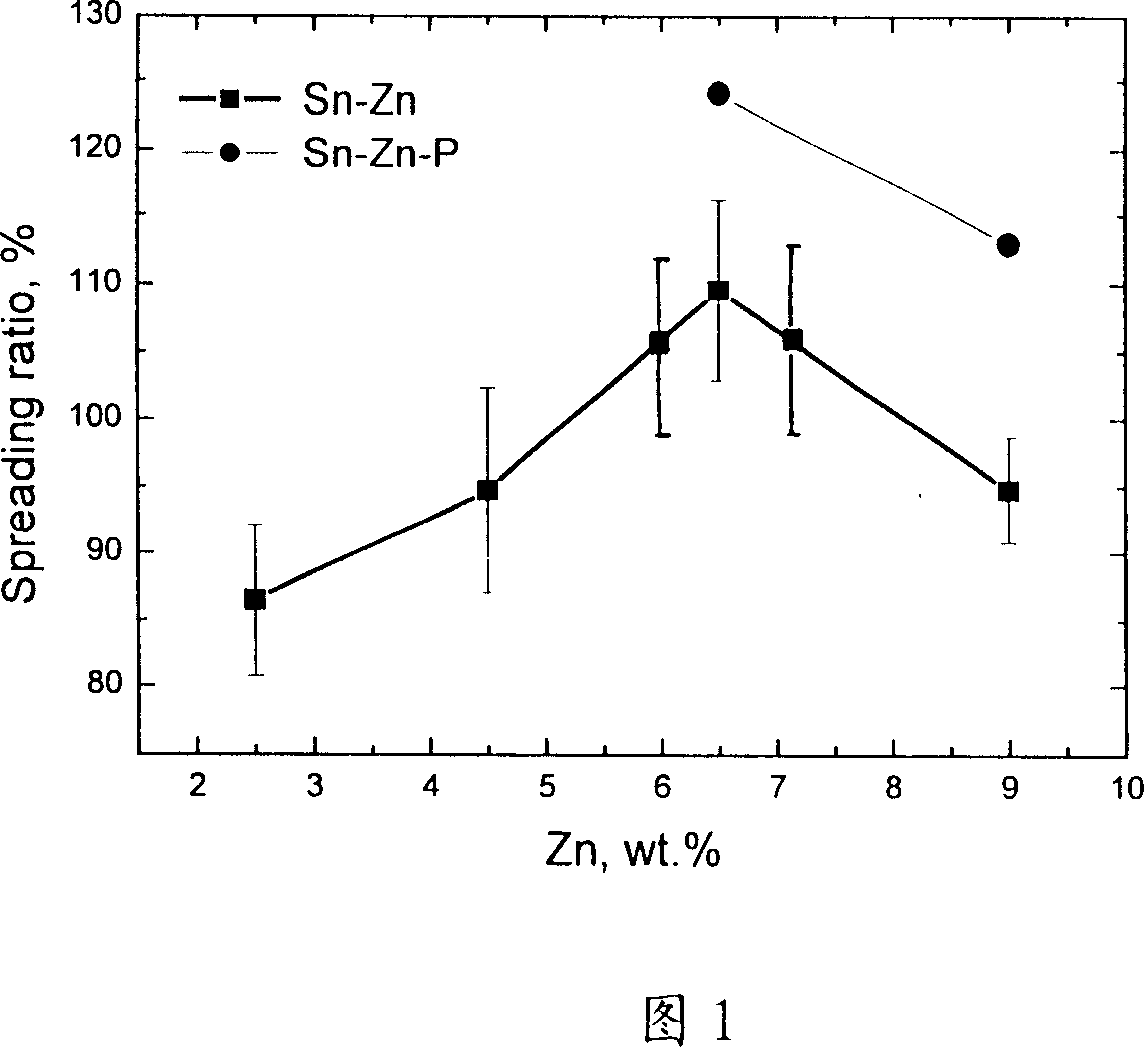

[0046] (1) hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 6.5% of the total weight of the alloy, and the content of phosphorus is 0.5% of the total weight of the alloy, The rest is tin.

[0047] (2) hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 9.0% of the total weight of the alloy, and the phosphorus content is 0.5% of the total weight of the alloy, The rest is tin.

[0048] Take the melted Sn-6.5 and 9.0%wt Zn alloy as the base material, take 100 grams each of the two base materials and melt them in a corundum crucible in a resistance furnace and heat up to 370°C. The surface is protected with graphite powder and wrapped with tin foil. Each 0.5 g of red phosphorus powder was quickly pressed into the melt and stirred, kept warm for 10 minutes and then cooled down to 300 °C, and cast into a φ5 ...

Embodiment 2

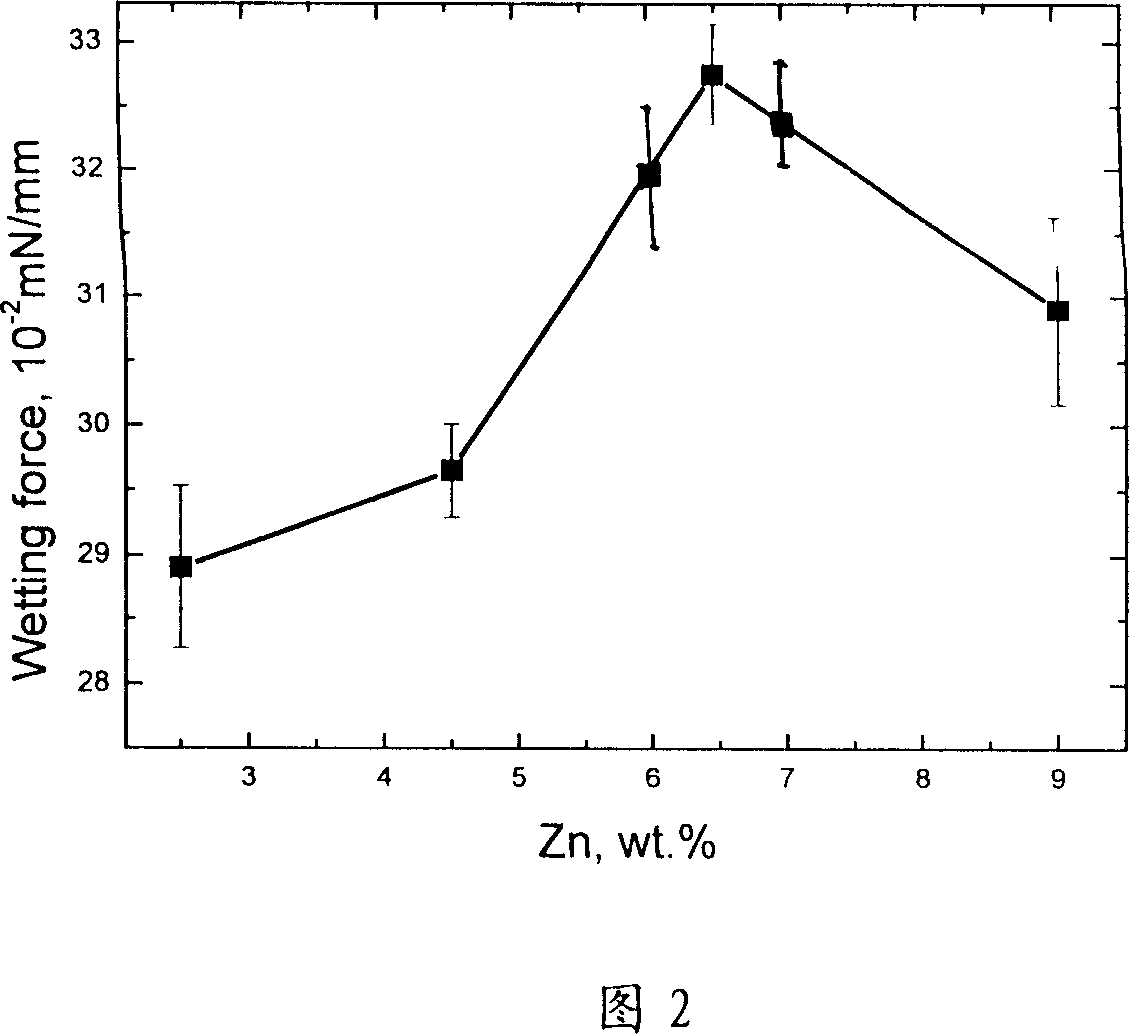

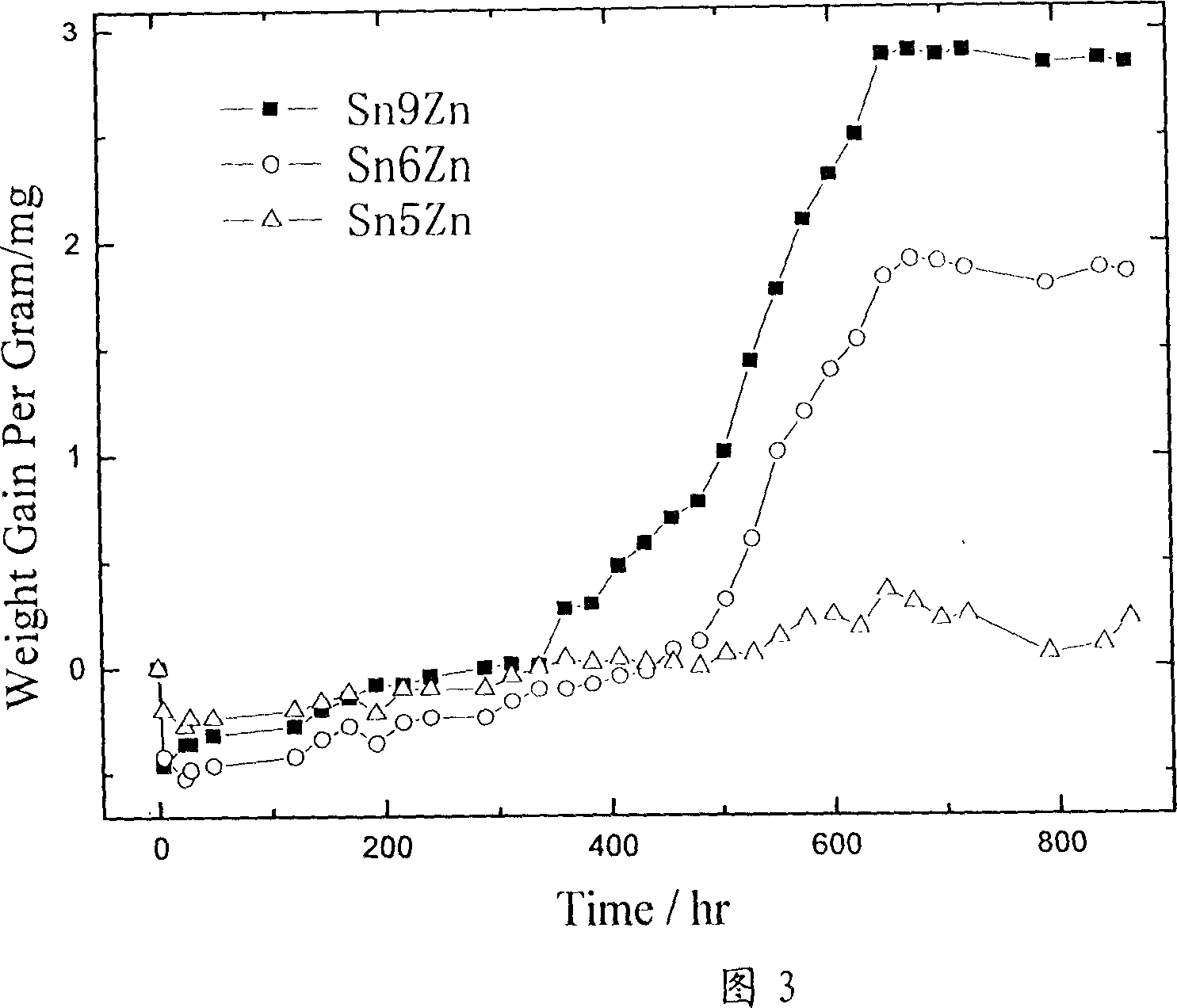

[0051] (1) Hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 2.5% of the total weight of the alloy, and the rest is tin.

[0052] (2) Hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 4.5% of the total weight of the alloy, and the rest is tin.

[0053] (3) Hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 6.0% of the total weight of the alloy, and the rest is tin.

[0054] (4) Hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 6.5% of the total weight of the alloy, and the rest is tin.

[0055] (5) Hypoeutectic tin-zinc alloy-based lead-free solder, wherein: the zinc content of the hypoeutectic tin-zinc alloy-based lead-free sol...

Embodiment 3

[0060] The hypoeutectic tin-zinc alloy-based lead-free solder, wherein the zinc content of the hypoeutectic tin-zinc alloy-based lead-free solder is 6.3% of the total weight of the alloy, and the rest is tin. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com