Engine with two port fuel injectors

A fuel injector and intake port technology, which is applied in the field of engines with two intake port fuel injectors, can solve the problems of reduced fuel economy, increased system cost, assembly of direct fuel injectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

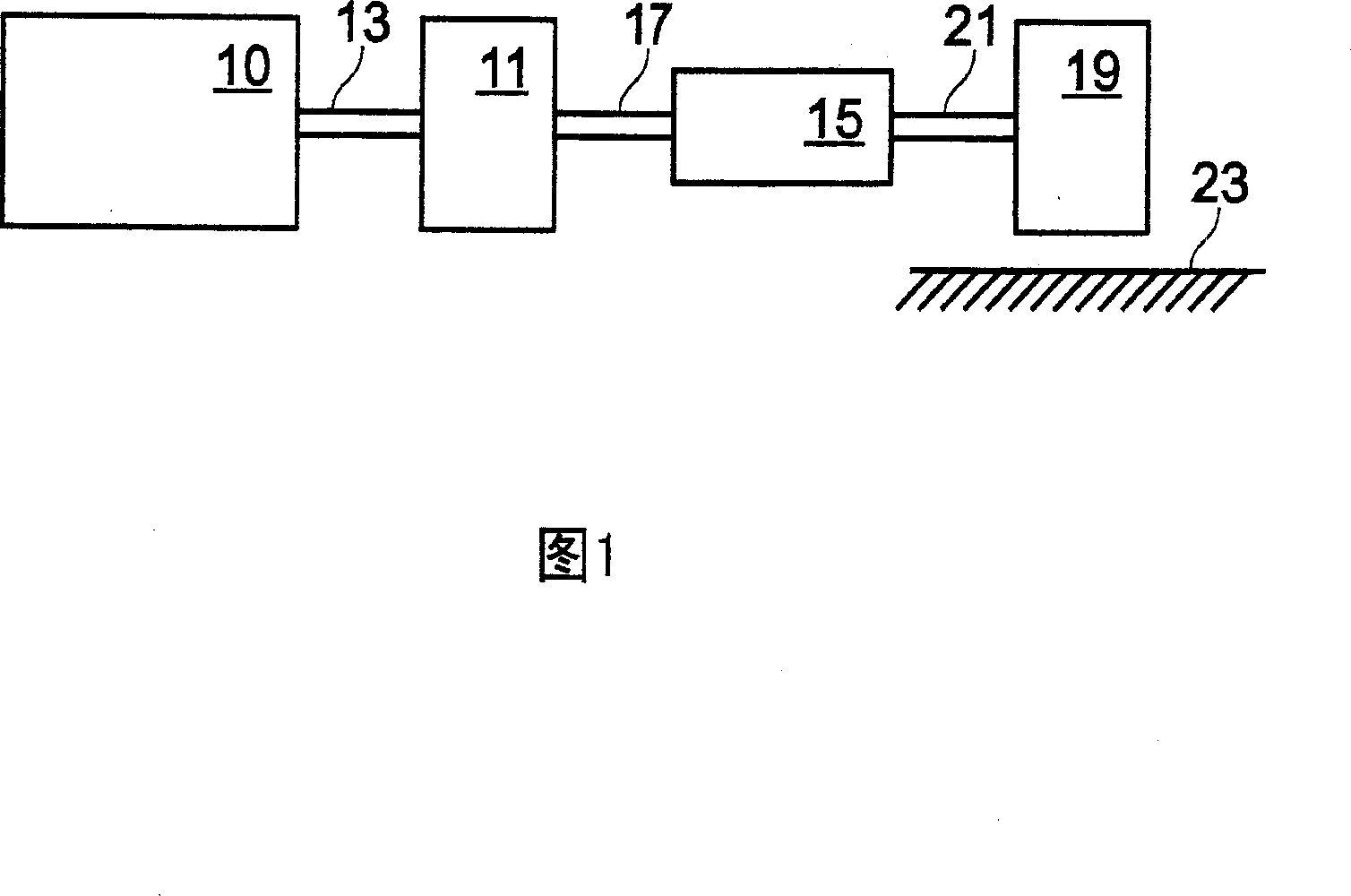

[0042] Referring to FIG. 1 , in this example, an internal combustion engine 10 , described in further detail herein with reference to FIGS. 2 and 3 , is shown coupled to a torque converter 11 via a crankshaft 13 . The torque converter 11 is also connected to a transmission 15 via a turbine shaft 17 . The torque converter 11 has a bypass or lock-up clutch 14 that may be engaged, disengaged, or partially engaged. When the clutch is disengaged or partially engaged, the torque converter is in the unlocked state as described. The lock-up clutch 14 may be, for example, electrically actuated, hydraulically actuated, or electrohydraulically actuated. The lock-up clutch 14 receives a control signal (not shown) from a controller, as described in more detail below. The control signal may be a pulse width modulated signal for engaging, partially engaging, and disengaging the clutch based on engine, vehicle, and / or transmission operating conditions. The turbine shaft 17 is also referred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com