Precision current sensor used for electric machine control

A current sensor, motor control technology, applied in the direction of DC motor speed/torque control, excitation or armature current control, control system, etc. problems, to achieve the effect of maintaining output accuracy, accurate current detection, and accurate current measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

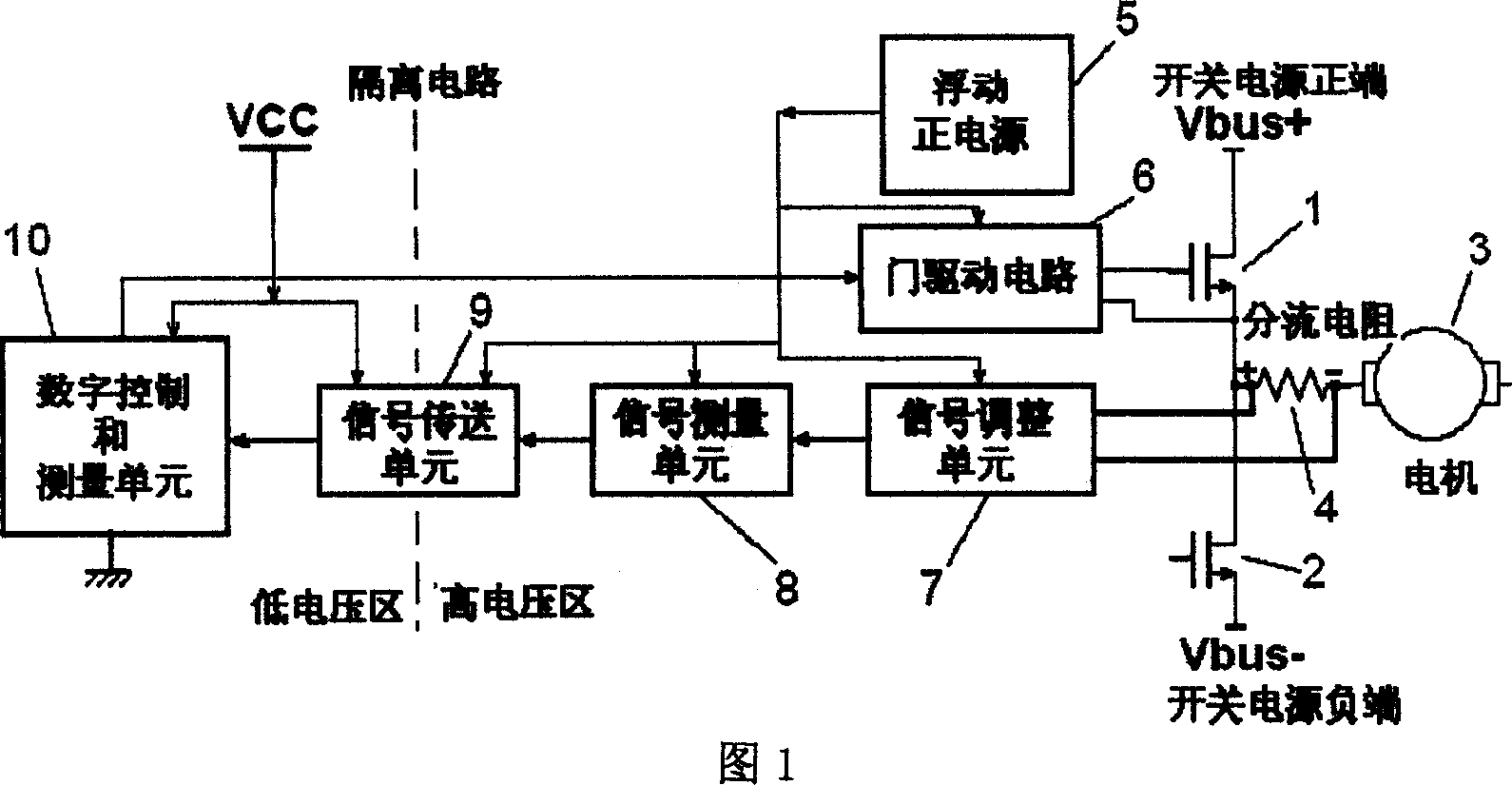

[0052] The present invention will be illustrated further in the following description, and the parts in the figure will be represented by their numbers throughout the text.

[0053] Made according to the characteristics of the present invention, Fig. 4 is a new precise current sensor system, this circuit system includes shunt resistor 4, a signal adjustment unit 19, a signal transmission unit 20, and a level shift unit 21. The original signal measuring unit 8 in Fig. 1 is omitted in this design, thereby simplifying the circuit, reducing the cost, and greatly eliminating the signal delay caused by this component.

[0054] FIG. 5 is an implementation of the signal conditioning unit 19 in the new sensor system (FIG. 4), which features a differential amplifier 24 to linearly amplify the current signal from the shunt resistor.

[0055] Another feature of the present invention is that only resistors are used as feedback and input elements in the amplifier 24, and the input resistors...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap