Method for surface treatment of aluminum alloy

A technology of aluminum alloy surface and surface treatment, applied in the direction of metal material coating process, etc., can solve problems such as cost increase, and achieve good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

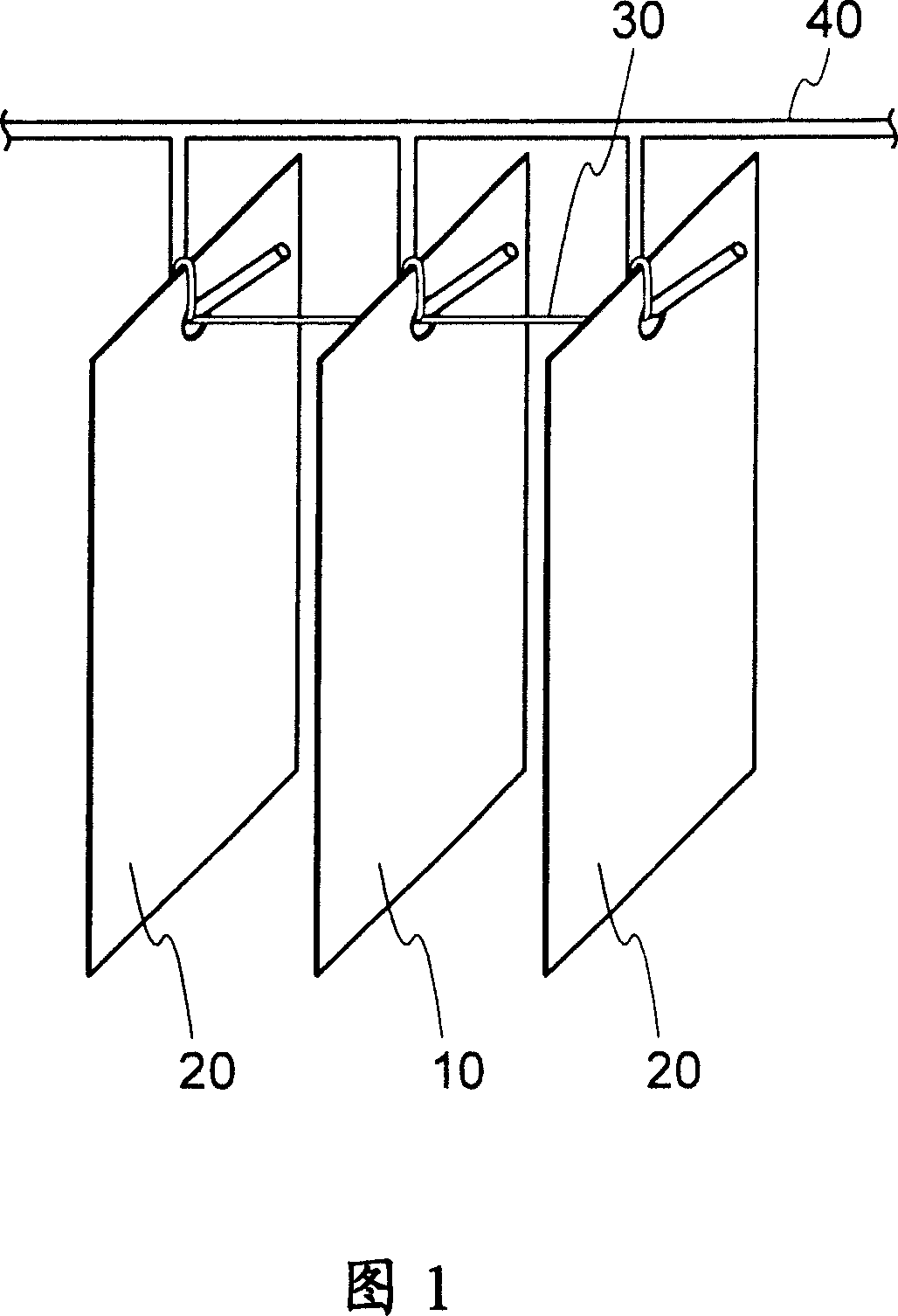

Image

Examples

Embodiment

[0056] Hereinafter, the present invention will be described in further detail based on examples, but the present invention is not limited thereto.

[0057] (Example 1-7, Comparison 1-5)

[0058] (processing object raw materials)

[0059] In any of Examples 1 to 7 and Comparative Examples 1 to 5, the same aluminum alloy was used as the raw material to be processed. Specifically, an aluminum alloy having a copper content of 0.01% by mass or less, 0.1% by mass, and 0.2% by mass is used. The size of the aluminum alloy is 70mm×150mm, and the thickness is 0.8mm. These aluminum alloys were ground through #180 sandpaper using a double action sander ("905B4D" manufactured by Compact Tool Co., Ltd.) and used as raw materials for processing. In addition, among these aluminum alloys which have been solidly ground, the aluminum alloy which makes SPC contact conduction is used as the raw material to be processed, and this SPC has the same size and thickness as the aluminum alloy. That i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com