Water-permeable paving and method for producing a paving

A ground covering and sand layer technology, applied to the pavement paved with prefabricated blocks, cohesive pavement paved on site, pavement details, etc., can solve the problems of lack of foundation connection, damage to the mechanical stress of the outer layer, etc., and achieve pressure The effect of load capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

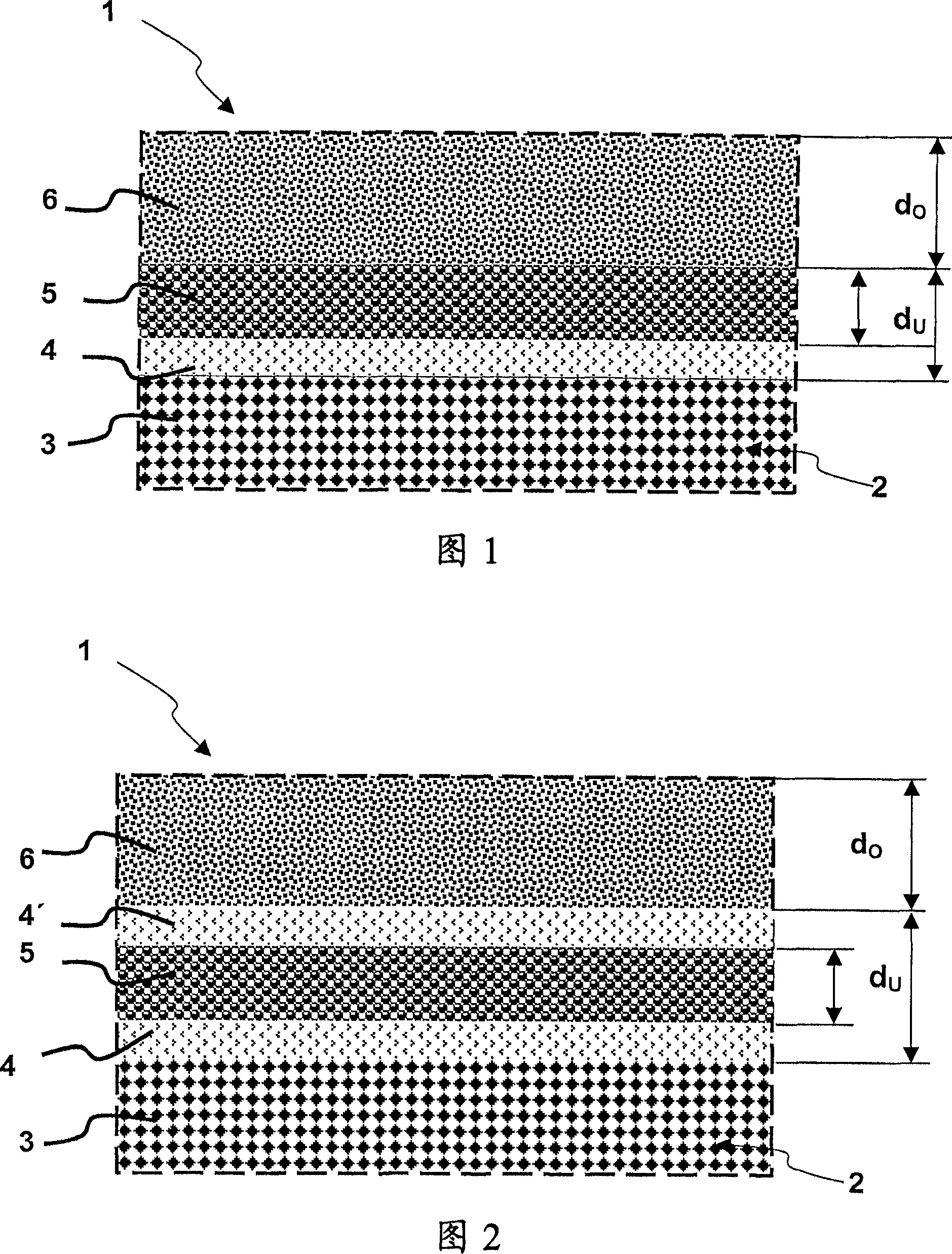

[0040] FIG. 1 schematically shows the multilayer structure of a floor covering 1 according to the invention in a cross-sectional view. The floor covering has three layers in the present embodiment, the lowest layer, the substructure 2 , being laid on the foundation 3 . Before the substructure 2 can be laid, the foundation 3 must first be prepared. Dig the foundation to a frost protection depth of 40 to 60 cm. The excavation depth depends on keeping the connection between the substructure 2 and the foundation 3 unaffected by the erosive effects of the freeze-thaw transition.

[0041] The substructure 2 itself consists of a layer of sand on the foundation side, the so-called sand layer 4 , and a crushed stone layer 5 lying thereon. In addition, firstly a filler material consisting of cement and sand is prepared, which are mixed with one another. The bonding material is a two-component polyurethane bonding material. It is also possible to use two-component epoxy resin adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com