Bacillus and production of monodesmosidic panasaponin and aglucon therewith

A technology of bacillus and ginsenosides, applied in the directions of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of occupying land, polluting the environment, etc., and achieve the advantages of reducing emissions, high product recovery rate, and simple and convenient methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

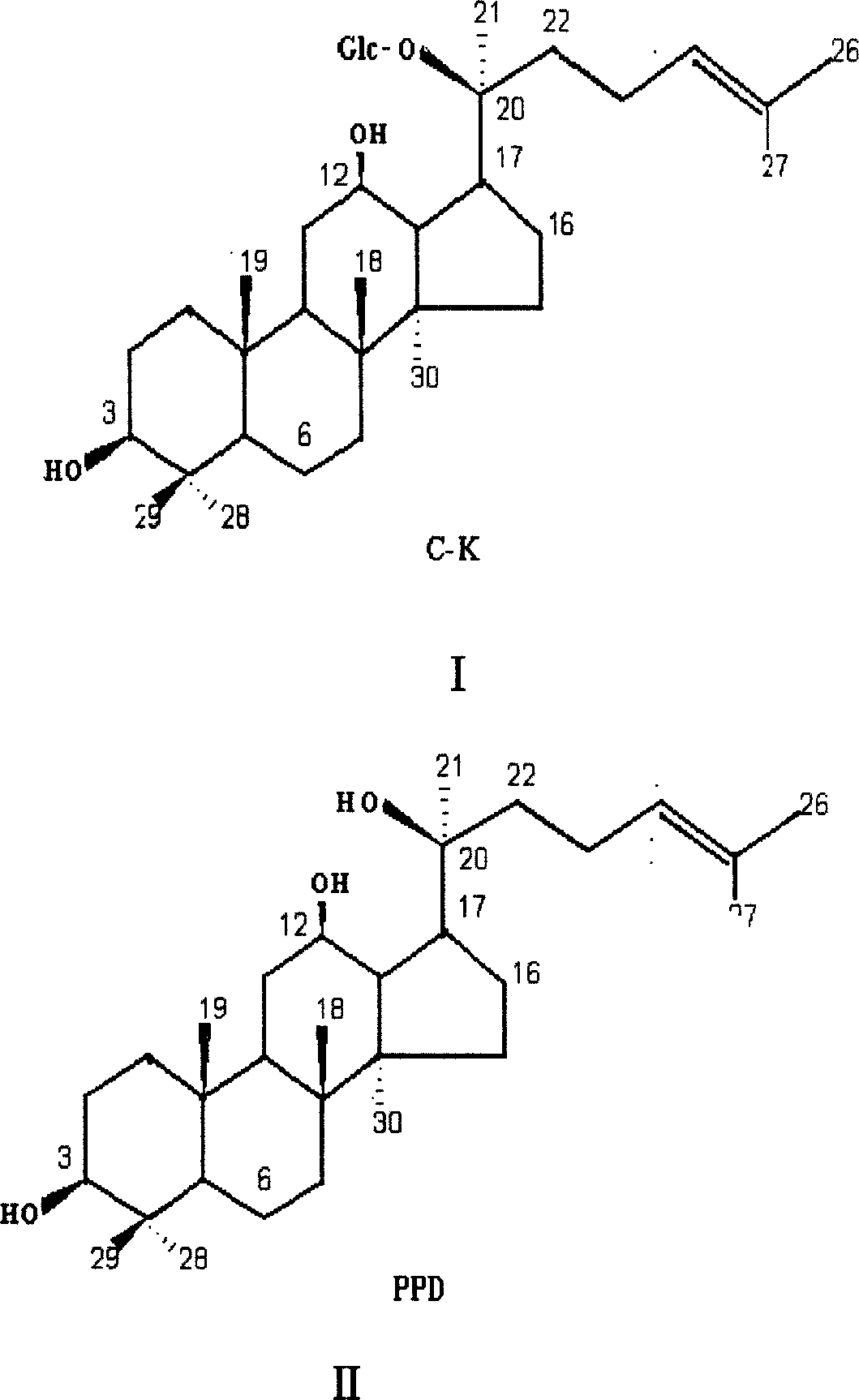

[0075] Transformation of Panax notoginseng stem and leaf saponins by A8

[0076] Inoculate the A8 cultivated under optimal culture conditions into an aqueous solution containing 10 g of notoginseng stem and leaf saponins (content > 80%). -1 , Conversion (hydrolysis) under natural pH conditions. Sampling starts after 3d. The results of TLC showed that compared with the control group, the spots of C-K, PPD and PPT gradually increased and the color deepened with the prolongation of time, while the content of Rb, Rd and Rg with larger Rf value in the stem and leaf saponins of Panax notoginseng decreased correspondingly . After 13 days of transformation, the reaction product was passed through a 0.2μm-0.45μm microporous membrane to remove microorganisms, and then injected into a D101 macroporous adsorption resin column, washed with water until colorless, and then washed with ethanol gradient to wash the resin column. The 80-90% ethanol eluate was concentrated and evaporated to d...

Embodiment 2

[0078] Transformation of ginseng fruit glycosides by A8

[0079]Inoculate the A8 cultivated under optimal culture conditions into an aqueous solution containing 1 g of ginseng fruit glycosides (content > 60%), at a temperature of 30°C and a shaker rotation speed of 160 r min -1 , Conversion (hydrolysis) under natural pH conditions. After 13 days of transformation, the reaction product was passed through a 0.2 μm microporous membrane to remove microorganisms, then injected into a D101 macroporous adsorption resin column, washed with water until it was colorless, and then washed with an ethanol gradient to wash the resin column. The 80-90% ethanol eluate was concentrated and evaporated to dryness to obtain 0.24 g of a mixture of C-K, PPD and PPT, with a conversion rate of 24%.

Embodiment 3

[0081] Transformation of American Ginsenosides by A8

[0082] Inoculate A8 cultivated under optimal culture conditions into an aqueous solution containing 2g American ginsenoside (content > 90%), transform (hydrolyze under the conditions of 160r min-1 and natural pH value at a temperature of 30°C) ). After 13 days of transformation, the reaction product was passed through a 0.2 μm microporous membrane to remove microorganisms, then injected into a D101 macroporous adsorption resin column, washed with water until it was colorless, and then washed with an ethanol gradient to wash the resin column. The 80-90% ethanol eluate was concentrated and evaporated to dryness to obtain 1.16 g of a mixture of C-K, PPD and PPT, with a conversion rate of 58%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap