Heat exchange device

A technology of heat exchangers and heat, applied in heating methods, household heating, indirect heat exchangers, etc., can solve the problems of reducing heat transfer and enhancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

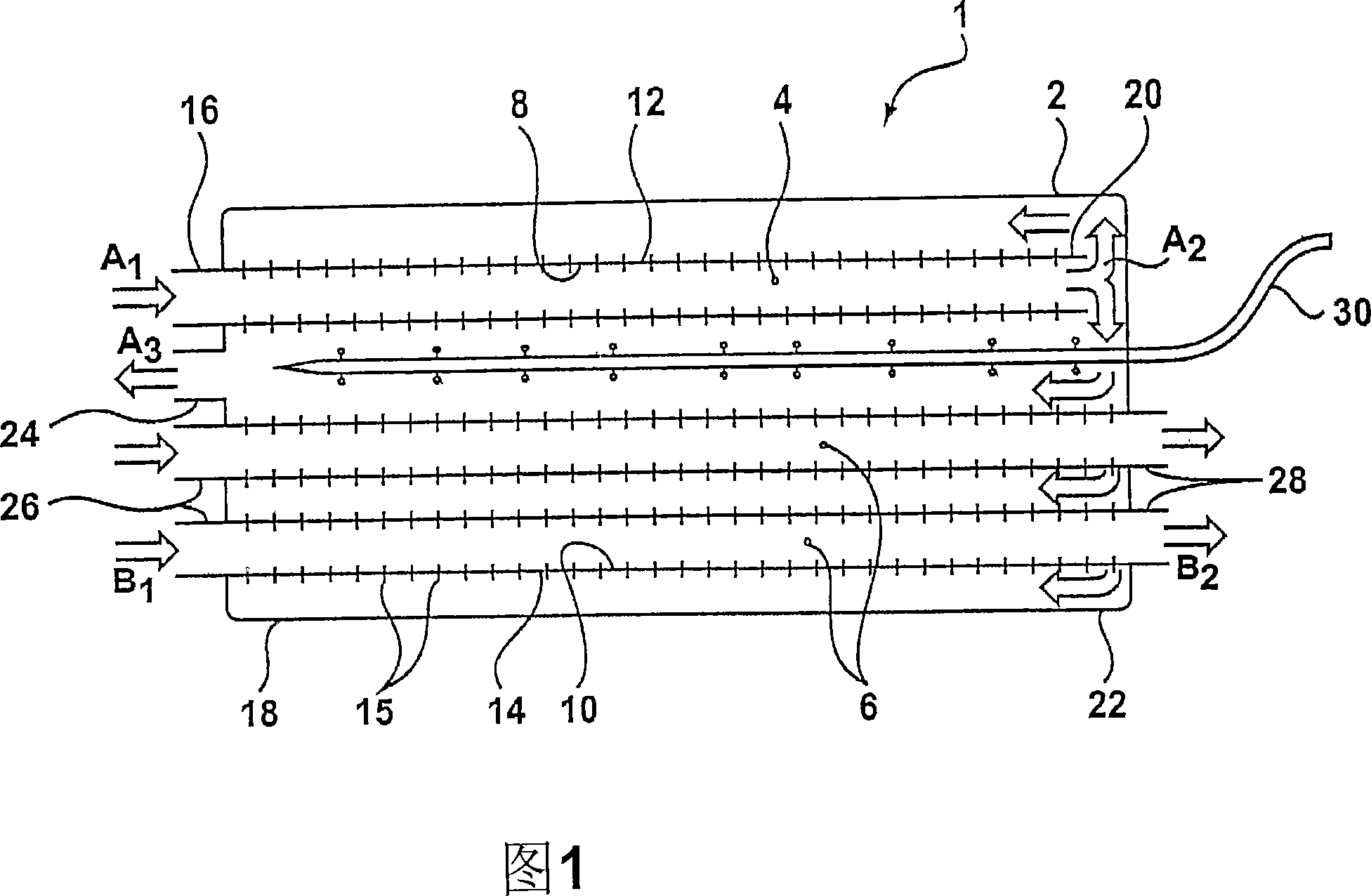

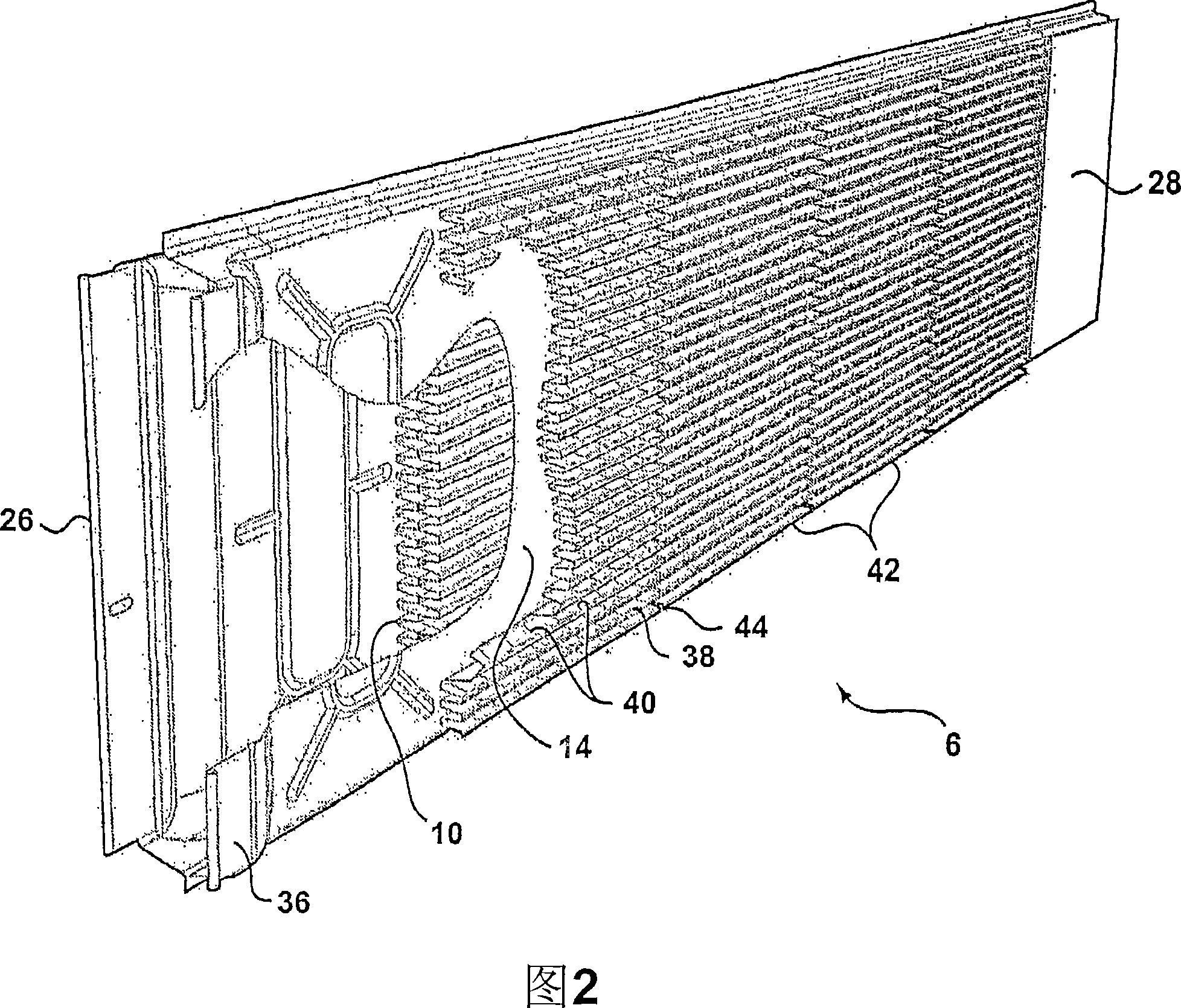

[0033] Fig. 1 shows a schematic diagram of an evaporative heat exchanger 1 according to the invention. The heat exchanger 1 comprises a generally elongated housing 2 in which working channels 4 extend. A plurality of product channels 6 also pass through the housing 2, the product channels 6 and the working channel 4 being generally parallel and spaced apart from each other. The working channel 4 and the product channel 6 respectively have a main surface 8, 10 arranged inside the channel, and a secondary surface 12, 14 arranged outside the channel. The working channel 4 and the product channel 6 are provided with a plurality of heat conducting elements 15 in the form of cooling fins.

[0034] The working channel 4 has an inlet 16 disposed externally of the housing 2 adjacent a first end 18 . An outlet 20 of the working channel 4 is provided in the housing 2 adjacent to the second end 22 . The housing 2 is also provided with a discharge opening 24 adjacent the first end 18 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com